Tandem Press Brake: The Next Level in Metal Bending

Metal bending is an important process in the manufacturing industry, the same as JUGAO's conical rolling machine. It involves shaping metal sheets, pipes, and other materials into specific shapes and forms for various applications. One of the most innovative and efficient tools used in this process is the tandem press brake. We will explore the advantages, innovation, safety, use, service, quality, and application of tandem press brakes.

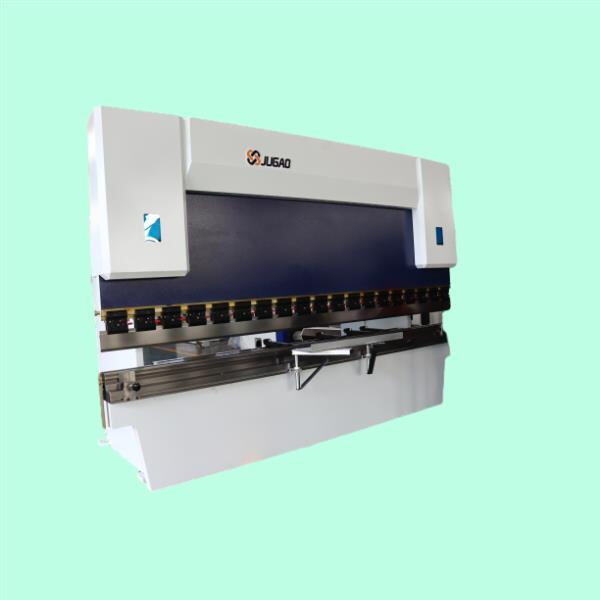

Tandem press brakes are designed to bend metal sheets with precision and high efficiency, identical to laser welder price developed by JUGAO. They are equipped with two or more hydraulic press brakes that work in unison to bend long, wide, and thick materials. The main advantage of tandem press brakes is their high production capacity. They can bend large volumes of metal sheets at once, making them ideal for mass production. This saves time, reduces labor costs, and increases profitability.

Another advantage of tandem press brakes is their versatility. They can be used to bend different types of metals, including Aluminum, stainless steel, and copper. They can also be used to create various shapes and forms, such as U-shaped channels, V-shaped channels, and box-shaped components. This makes them suitable for a wide range of applications, including the automotive, aerospace, and construction industries.

Tandem press brakes are continuously evolving, thanks to technological advancements in the manufacturing industry. The latest innovations in tandem press brakes include fully automated systems that can operate without human intervention. These systems use sensors and algorithms to optimize the bending process, ensuring accuracy and consistency. They also come with advanced software that allows for easy programming, monitoring, and control of the machine.

Another innovation in tandem press brakes is the use of servo-electric motors, similar to the JUGAO's product like fiber laser for cutting metal. These motors are more energy-efficient compared to hydraulic motors and provide better performance in terms of speed, precision, and noise reduction. They also require minimal maintenance, making them cost-effective in the long run.

Safety is a top priority in the manufacturing industry, and tandem press brakes are no exception, just like the fiber laser for cutting metal built by JUGAO. These machines are equipped with safety features that protect operators from accidents and injuries. One of the main safety features is the light curtain, which uses sensors to detect any intrusion into the bending area. When an object or person enters the area, the machine stops automatically, preventing accidents.

Another safety feature is the emergency stop button, which allows operators to stop the machine instantly in case of an emergency. Tandem press brakes are also designed to have a low noise level, reducing the risk of hearing damage to operators.

Using a tandem press brake requires proper training and experience. Operators must understand how to program the machine, select the appropriate tooling, and load the material properly. They must also be aware of the safety features and follow the standard operating procedures to prevent accidents.

To use a tandem press brake, operators must first input the bending parameters into the software, identical to JUGAO's product auto pipe bending machine. These parameters include the material type, thickness, width, and bending angle. Once the parameters are set, the machine automatically selects the appropriate tooling and clamps the material in place. The operator then presses the start button, and the machine starts bending the material according to the programmed parameters.

tandem press brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales tandem press brake well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; tandem press brake, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond tandem press brake market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.