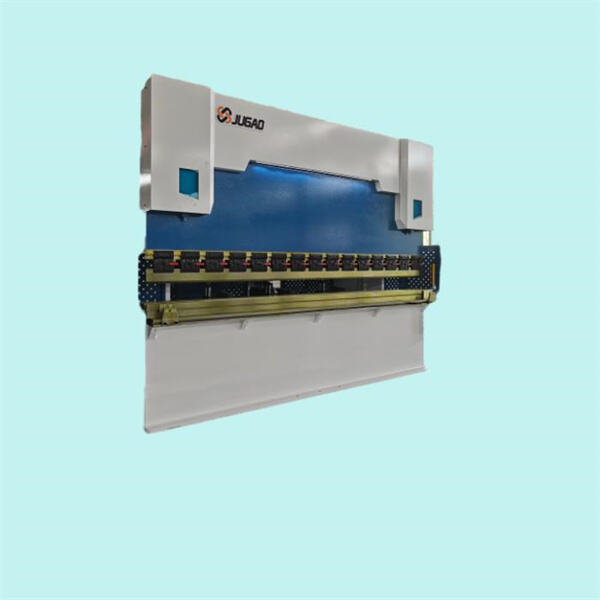

Hydraulic press brakes are machines that will assist in bending and forming pieces of metal for a wide range of projects. These machine also can be found from factories and workshops where metal worked product manufacture. The hydraulic press brakes can do this by using a little bit of force to push on metal sheets and change them into the specific shapes that you need for it. They range in size from tiny appliances suitable for small tasks to types that are gigantic enough to crush boulders. Hydraulic press brake is a kind of sophisticated, high precision sheet metal processing machinery. The hydraulic bending machine consists with header, rack backing board, stamping column and compound die teeth. The above's figure about the size also depends on what work to choose delineations or not.

Hydraulic hydraulic Press brake:role under the hydraulics, a mechanical press is called. These are cylinders that have contained a special liquid called as hydraulic fluid, through-which pressure generated. This is actually the liquid that allows for your machine to make exact forces about the steel sheets. To operate them, a worker steps on a foot pedal that activates the hydraulic pump to make fluid exert more force. It causes this pressure rise to travel back towards the cylinder, which in turn presses on a sheet of metal into a bending tool. The machine repeats this process until the metal takes on a suitable shape such as required angle or curve for performing that project. The entire operation allows for excellent control of the bending.

They are essential tools used in the factories because through them everything is produced with a good precision. The result is they can produce things that go well together, a critical requirement in many manufacturing processes. This decreases waste by only throwing away pieces of metal which are not being used. The factories can save a lot of money and material when they bend the products with hydraulic press brakes. Also, these machines make it easier for historians to do more in a shorter period of time - and that is super important when you are talking about factories which have lots other places competing with then. In fast manufacturing worlds, getting things done efficiently is a must to stay ahead.

Hydraulic press brakes are also customizable to do a variety of metalworking applications, which is one of the best things about them. In addition, they frequently have other mechanisms improving their capability of function including back gauges and tool holders as well as bed extensions. The back gauge is a time-saver for the worker where placing how far that metal sheet travel before it bends This functionality is guaranteed that all your work remains detailed and neat in the output. With these capabilities, buying a hydraulic press brake that is complimentary to your applications and part drawings can have the rewards of cost savings in depreciation fees for tooling and workstations. This automation ensures that chances of errors are minimized and the process is completed more smoothly, effectively.

When utilizing hydraulic press brakes, safety is the most import. These machines are designed with multiple safety features that keep the workers in charge of them safe. As an example, emergency stop switches that enable the operator to rapidly halt device operation in case of an immediate need. It also contains guards about the working area, along with light curtains that assists in preventing accidents. This improves worker safety when dealing with the machine. Hydraulic press brakes are a lot safer when you take into consideration that they automatically handle the bending, unlike certain other types of machines. Some need someone to manually head the metal, which can be very dangerous. Hydraulic press brakes are utilized to bend the steel part using hydraulic or electric. bending of sheet metal and This helps make it much less dangerous for employees while revealing that this material will always be shaped properly and similarly over time just by computerizing these processes.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond hydraulic press brakes market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

hydraulic press brakes specialize metal sheet forming high-quality production. Pipe Bending Machines flexible solutions pipe bending. product line focused efficiency, accuracy, stability, allows customers increase production efficiency improve quality products.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities hydraulic press brakes production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

recognize importance after-sales service RD advancement. press brakes, laser cutting machines, rolling machines, pipe bending machines, other products, provide entire range support after sales includes Spanish after-sales service, make sure customers enjoy hydraulic press brakes experience. same time, continue make investments research development encourage latest technology product development meet ever-changing needs customers, assist customers maintain position market.