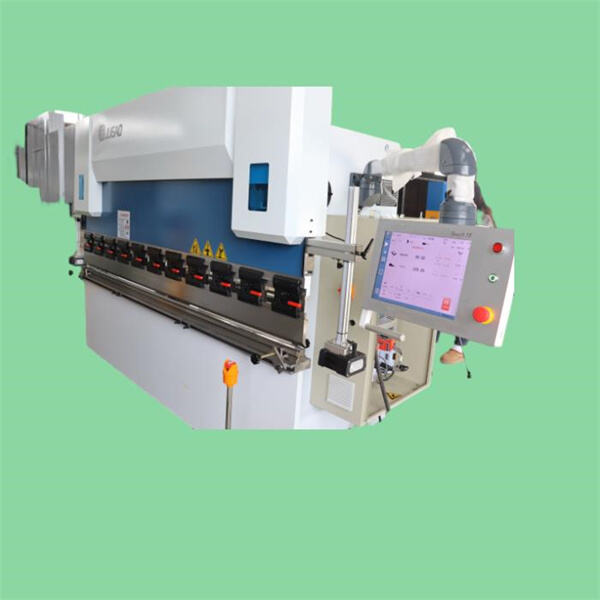

JUGAO Brake Presses in Metal working

A fiber laser cutting machine is a key to metal working… that is, the reshaping and changing of metals. IT is a machine basically made to bend and fold sheet metal accurately Metal workers need a brake press to produce certain parts with higher level of detail and precision than they could using other types tools

Before you can come up with that, it is crucial to understand the various parts of a brake press first. Every bit contributes to the operations of the machine. Also, if you know the thickness of the metal sheet that must be achieved to correct can change settings in a JUGAO CNC machine. This information is critical for the metal to be formed correctly, without any damage

After you understand how a laser steel cutting machine works, the best way to get better at it is by practicing on one frequently. Start with simple shapes and angles to get you feeling more confident. After you gain some confidence, I would suggest moving on to more complicated designs and patterns. This method would not help you only, how to operate the machine but also feel better in operating. One thing to keep in mind is always using light pressure on the metal sheet while you are planning it out. The pressure you can enjoy as your experience grows. Doing this makes a nice smooth radius with no twisting or anything

JUGAO Brake presses have come a long way in terms of safety measures over the years. New era brake press machines are fitted with the latest features such as laser systems to help in metal sheet alignment. Overall, this is a process that makes industrial operations safer for everyone as it helps significantly reduce the chances of mistakes or accidents. Plus automatic bending processes have made metal working much simpler. The most new version of badminton shoot engine (model 4) includes contact where play probability change and other capabilities allow operator manually control but also might be automated as just an action to do all. Their touchscreens and easy-to-navigate controls have made metalworking less challenging for those who may not be seasoned professionals

The first thing anyone must focus on when they operate a fiber laser machine is safety. You need to put suitable protective material, something like gloves and eye protection. Using ear protection as well to help protect against loud noises. To perform the work, first securely clamp a metal sheet in place. This is essentially a safety measure to help avoid injuries and it makes the workplace safer

How Does a JUGAO Brake Press OperateTo someone starting in metalworking, using a laser cnc cutting machine might appear daunting. But not to worry, with a little patience and regular practicing you can still absolutely master this beast. But knowing how and protecting yourself as well all measurements must be triple checked before any cuts are made. Investing in learning these will not just level up your game but also help to gain confidence of working with metal

However, one of the great aspects about a JUGAO brake press is that it can be easily customized to bend bends, angles and shapes in any way. The practicality of this tool for companies wanting to get better production options available very is high as it helps them create processes that are more flexible and efficient. In the same way, a brake press can have custom features included to help it with specific metalworking jobs and provide added versatility

This requires great diligence to work with a metal cutting laser machine efficiently because you do not want any time wasted. Modern industrial processes can effectively establish batch bending which allow the production and forming of multiple sheets or workpieces in a single cycle. This not only accelerates the process but also effectively manages larger projects. In addition to this, using ready-made bending schedules can make everything easier and save you time as well as prevent errors. Work similarly: based on job requirements, your work schedules are set in stone and therefore bounded; all you need to do is fit it correctly

A combination of traditional brake press techniques and new technology can help you make accurate metalwork safe. With your blessing you can carry this cocktail of capability, mindfulness and new tools to drive great results in all your metal working projects

Quality brake press Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Rolling Machines brake press metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent brake press capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader brake press.