Do you wonder how metals are cut into a desired shape? Then the metal cutting laser machine is your answer if you do. This machine uses the power of light to cut through metal materials into the shapes that are precise we need. There is more to this JUGAO metal cutting laser machine than meets the optical eye, and below are five subtopics to guide you through its world.

Firstly, let's explore the various advantages of using a metal laser machine cutting. This technology is faster and more precise unlike traditional cutting methods. Additionally, it can cut through thick layers of metal without producing any waste or damage. JUGAO metal cutting fiber laser also reduces the amount of energy needed to power the machine, saving you both right time and money.

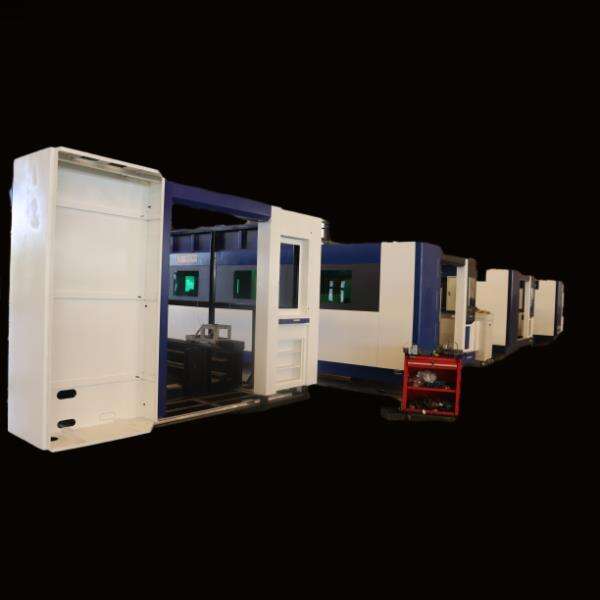

The metal laser cutting is a remarkable innovation that has changed the world of manufacturing. Before the advent of this machine, cutting metals was laborious and time-consuming. The JUGAO laser cnc cutting machine is sophisticated, consisting of a laser, optics, and other components that are essential together to create precise cuts in metal. It is a game-changer in the manufacturing industry and has made metal cutting easier, faster, and more accurate.

Using the metal laser cutting requires safety precautions. High energy is required to create the light intense cuts through metal. As a result, it is crucial to use personal equipment protective when handling the machine. This includes safety glasses, gloves, and clothing protective. Additionally, the JUGAO laser steel cutting machine must be operated and installed by trained professionals to prevent accidents. Safety first!

Now, let's talk about the simple steps to follow when using a metal laser machine cutting. Firstly, install the JUGAO fiber laser cutting machine and ensure that all the connections that are necessary in place. Next, turn on the machine and set the laser power to the level required. Step three, load the metal materials that need cutting onto the machine's work table. The step final to activate the machine, and watch it cut through the metal with ease.

Rolling Machines specialize metal sheet forming high-quality production. metal cutting laser machine offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

understand metal cutting laser machine RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Quality Builds metal cutting laser machine: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle metal cutting laser machine materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.