Do you need to cut metal for a project at school or at home? A solution is had by us for that! A plasma metal cutter is a tool powerful uses a gas to create an electric arc that cuts through metal with ease. This tool is an innovation in JUGAO plasma metal cutter, making it simpler and faster to complete projects that require metal cutting. The part best? It's safe to use and offers advantages that are countless anyone who needs to cut metal!

A plasma metal cutter offers many advantages over traditional metal methods that are cutting. It's faster, more efficient, and precise, which means you can get the working job done in no time. This JUGAO laser cutting machine metal also produces less heat, which means there's less chance of the metal warping or bending during the cutting process. Additionally, the plasma metal cutter can cut through materials other cutting tools can't, such as aluminum, copper, and steel stainless.

The plasma metal cutter is a revolutionary innovation in the metal industry cutting. It has changed the real way people cut metal by offering a faster, more efficient, and safer method. With the use of gas and an arc electric metal cutting has never been easier or more accessible to everyone. Plus, as technology continues to advance, the JUGAO laser cutter metal shall only get better!

When using a plasma metal cutter, it's crucial to follow safety guidelines to ensure operation safe. Always wear gear protective such as for instance gloves and goggles, to protect your hands and eyes. Additionally, ensure the ongoing work area is clear and free of flammable materials to avoid accidents. JUGAO metal cutting laser machine also essential to regularly maintain the tool and follow the manufacturer's instructions for safe operation.

Using a plasma metal cutter is straightforward. Here are the steps that are necessary

1. Collect the materials you need, including the plasma metal cutter, protective gear, metal to be cut, and any clamps.

2. Connect the JUGAO metal laser machine power supply to a charged power source and turn it on.

3. Adjust the settings on the tool for the thickness of the metal you're cutting.

4. Put on protective gear before positioning the metal and clamping it in place on the ongoing work surface.

5. Turn on the plasma metal cutter and move it across the metal to cut it.

6. turn the plasma metal cutter off and unplug it from the power supply when you finish.

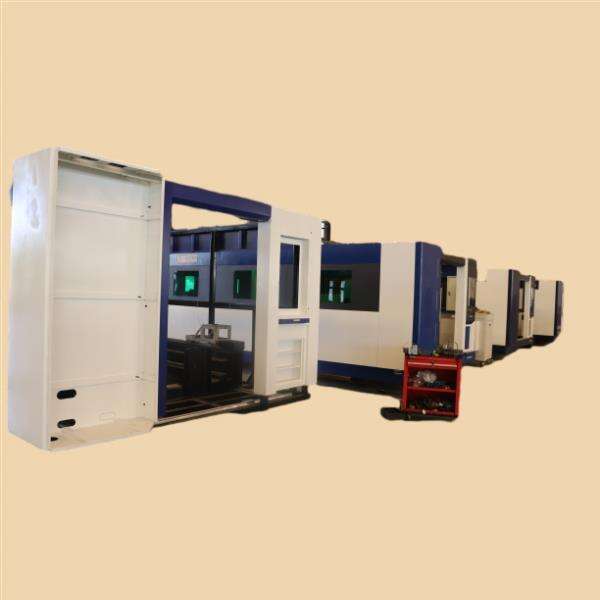

Quality Builds Trust: Dedicated sheet metal machines carefully monitor each machine's quality ensure conforms industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease anxiety customers.respond rapidly plasma metal cutter demands through efficient production supply-chain management. time deliver can reduced week ample inventory. enables rapid equipment purchases competitive advantage.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; plasma metal cutter, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader plasma metal cutter.

Rolling Machines specialize metal sheet forming high-quality production. plasma metal cutter offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.