TITLE: Discover the Ultimate Advantages of Using a Metal Plate Roller

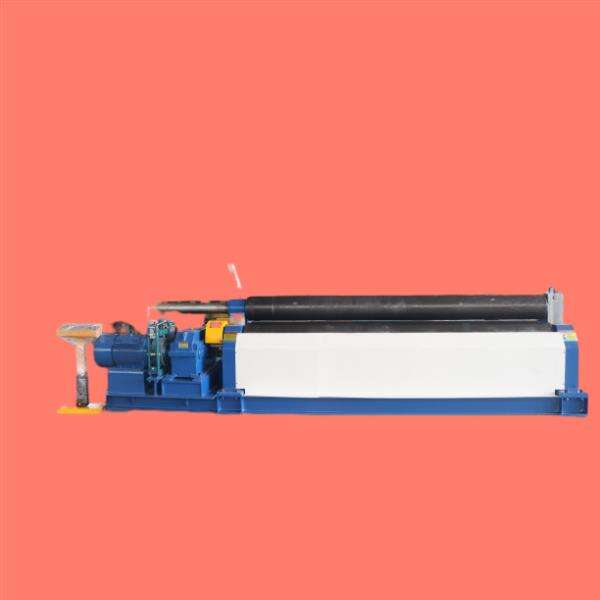

If you need to bend and curve metal plates for your artwork or custom projects, a metal plate roller is an essential tool to have. This innovative machine can roll sheets of metal into a variety of shapes with ease, and it's incredibly safe to use. In this marketing article, we'll explore the many advantages of using a JUGAO metal plate roller, discuss its unique innovations, provide tips on how to use it effectively, and explain the quality and service you can expect from this incredible machine.

The primary advantage of using a metal plate roller is its versatility. This machine can bend plates of all sizes into numerous shapes, including cylinders, cones, and spheres. Metal plate rollers are also incredibly precise, so you can make detailed curved shapes with ease. This machine also makes it possible to create large volumes of uniform curved shapes, which is useful for manufacturing settings.

Another advantage of a JUGAO metal plate roller is its sturdiness. Typically, these rollers are made of high-quality materials that can withstand heavy loads. This means you can use them regularly without worrying about wear and tear. Additionally, these rollers often come with adjustable rolls that can be used to roll different thicknesses of metal.

As technology progresses, new innovations are continually being introduced to improve JUGAO metal sheet roller. One of the latest innovations is the electronic control system. With this system, you can precisely control the movement of the roller through programmed commands. Electronic control systems allow for greater accuracy and efficiency, making it easier to make precise curved shapes in your metal plates.

Using a metal plate roller is typically very safe, especially when you follow the appropriate safety guidelines. One of the key safety features of modern metal plate rollers is the inclusion of safety guards. Safety guards protect your hands and fingers from getting caught in the machine while it is in operation. Additionally, many metal plate rollers come with emergency stop buttons that allow you to stop the machine quickly in case of an emergency.

Using a metal plate roller requires some expertise, but once you get the hang of it, it can be easy and efficient. First, make sure you have the appropriate size of metal plates that need to be rolled. Adjust the roller's tension and roll the metal plate slowly through the machine, exerting equal pressure on both sides. This will ensure that the JUGAO plate is bent uniformly and doesn't become misshapen.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe metal plate roller. product range focused efficiency, precision, stability help customers improve production efficiency quality products.

precision efficiency, metal plate roller cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

Quality metal plate roller Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales metal plate roller well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.