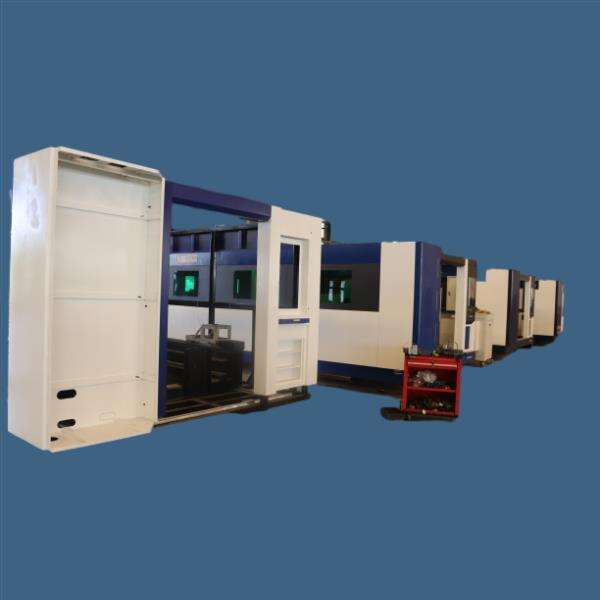

Are you looking for a device high-tech can cut, carve, and engrave materials with amazing precision? Look no further than the JUGAO laser cnc machine! we will explore the amazing advantages of this machine innovative exactly how it works, and how to use it safely and effectively.

Laser CNC machines are the tool perfect cutting and engraving materials such as wood, plastic, and metal. Here are some of the advantages of using a laser CNC machine:

Precision: The JUGAO fiber laser cnc machine uses a laser high-power to cut or engrave materials with incredible precision. This machine can cut materials as thin as 0.1mm.

Speed: The laser CNC machine can cut or engrave materials at incredible speeds, making it an tool ideal mass production.

Versatility: The laser CNC machine can cut or engrave a wide range of materials, including wood, acrylic, glass, and metal.

Effectiveness: The laser CNC machine eliminates the need for manual cutting or engraving. This machine can work continuously all day, saving you effort and time.

The laser CNC machine is a revolutionary innovation in the world of cutting and technology engraving. This machine uses a laser high-power to cut and engrave materials with incredible precision. The JUGAO laser cnc cutting machine is also equipped with advanced software that allows you to control every facet of the cutting and process engraving.

Safety is of utmost importance when using a laser CNC machine. This machine uses a laser high-power that can cause serious injury if not handled properly. Here are some safety tips when using a laser CNC machine:

Always wear protective goggles when using the machine.

Read and follow the manufacturer's instructions carefully.

Make sure the JUGAO laser steel cutting machine is properly grounded.

Do not leave the device unattended while in use.

Using a laser CNC machine is easy, but it does require some knowledge and skill. Here are some steps that are basic follow when using a laser CNC machine:

Prepare your material: Make yes your material is flat, clean, and securely fastened to the machine's bed.

Set the machine up: Turn on the JUGAO fiber laser cutting machine and calibrate the laser beam.

Load your design: Use the device's software to load your design or create a new one.

Start the machine: Start the machine and let it do its job.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader laser cnc machine.

laser cnc machine accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

laser cnc machine Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective laser cnc machine production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.