Introduction

You may have heard of a fiber laser welder if you are searching for a new and innovative way to weld metals. This JUGAO Fiber laser welder is great for people who work in manufacturing or construction, or anyone who needs to join metal parts together. we will explore the advantages of utilizing a fiber laser welder, how it works, and how to make use of it safely.

One of the greatest advantages of using a fiber laser welder is that it is incredibly accurate. This machine can make very cuts that are precise welds, which means that you could create intricate designs or repair small parts with ease. Another benefit is that it is very fast. You can weld parts together in a matter of seconds, which can save you money and time. Additionally, JUGAO laser welder for sale are very efficient because they use much less energy than other welding machines.

Fiber laser welding is a technology relatively new and it has quickly become very popular into the manufacturing industry. This is because it is more efficient and precise than traditional welding techniques. A dietary JUGAO fiber laser cutting machine uses a laser high-powered to melt the metal and fuse it together. One of the innovations that are key fiber laser welding is that it can work with a wider range of materials than other welding machines. This means it to join together metals that would be difficult to weld along with other methods which you can use.

As with any machine that uses lasers or heat high it really is essential to take certain safety precautions when using a fiber laser welder. Make sure you wear appropriate gear protective such as goggles and gloves, to prevent burns or eye damage. Additionally, factors to consider that the area around the welder is clear of any materials that are flammable debris. JUGAO fiber laser machine is also important to help keep the device properly maintained, as any malfunctions could lead to injuries or damage to the equipment.

Using a fiber laser welder is relatively simple, but it does require some training and practice it effectively before you can use. First, you need to make sure that the metal parts you want to weld together are clean and free of any debris or rust. Then, you need to position the right parts so that they are lined up correctly. Next, you need to turn on the JUGAO fiber cutting machine and adjust the settings to create the amount right of and intensity. Then, you can begin to weld the right parts together using the laser.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain fiber laser welder advantages.

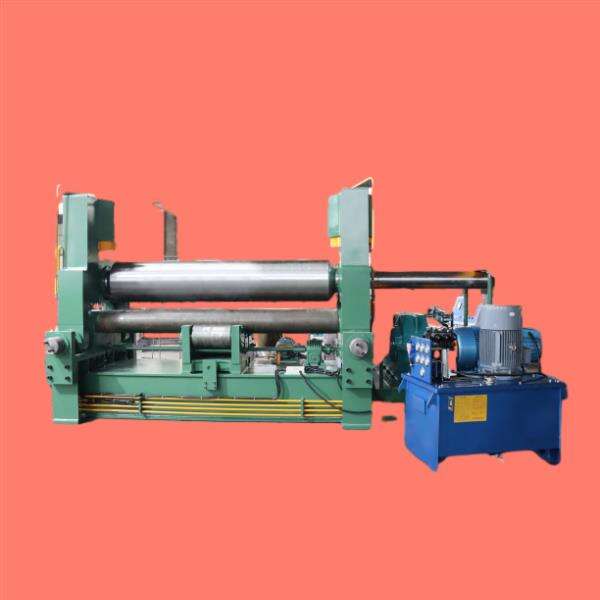

precision efficiency, fiber laser welder cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

aware importance after-sales service RD innovation. provide array after-sales solutions such fiber laser welderg after-sales press brakes, various products. same time, continue invest research development, support improvements products using latest technologies meet evolving needs customers help customers maintain leading position marketplace.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe fiber laser welder. product range focused efficiency, precision, stability help customers improve production efficiency quality products.