The Role of Press Brakes in Construction Machinery Manufacturing

In the realm of construction equipment manufacturing, precision engineering and structural durability are fundamental requirements. Press brakes serve as indispensable tools in this sector, enabling the precise bending and shaping of metal components that form the backbone of construction machinery. This comprehensive guide examines the critical functions of press brakes in construction equipment production and provides actionable recommendations for their optimal configuration and maintenance.

Essential Functions of Press Brakes in Construction Machinery

Fabricating Robust Structural Components

Press brakes are instrumental in manufacturing essential structural elements such as support frames and load-bearing beams that constitute the framework of construction equipment. The capacity to consistently produce components with precise dimensional accuracy is vital for ensuring the structural reliability of heavy machinery.

Processing Heavy-Gauge Materials

Construction equipment demands components fabricated from thick steel plates and other durable materials. Modern press brakes, particularly those with substantial tonnage capacities, are specifically engineered to process these demanding materials while maintaining component integrity and performance specifications.

Producing Customized Machine Parts

Contemporary construction machinery often requires specialized components tailored to specific operational requirements. Press brakes facilitate the production of customized parts, including unique mounting brackets and specialized protective enclosures, designed to meet the exacting demands of various construction applications.

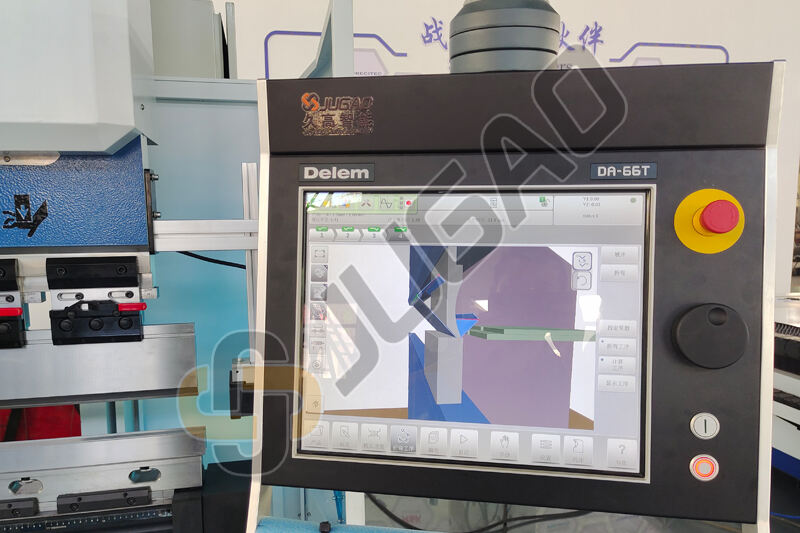

Enhanced Capabilities through CNC Integration

The incorporation of Computer Numerical Control (CNC) technology has significantly enhanced the versatility of press brake operations. This advanced integration enables rapid design modifications and operational adjustments while maintaining exceptional precision and minimizing production lead times.

Optimizing Press Brake Performance in Manufacturing

Configuring Press Brakes for Maximum Efficiency

Workspace Preparation

Prior to press brake operation, ensure the work area is properly organized and free from obstructions. A well-maintained workspace is essential for operational safety and efficiency. Verify that the equipment is positioned on a level surface to guarantee consistent performance accuracy.

Tooling Selection and Installation

Select appropriate tooling based on material specifications and component design requirements. Ensure proper installation and alignment of tooling components, as precise setup is critical for achieving accurate bending results.

Equipment Calibration Procedures

Conduct thorough calibration of the press brake by configuring backgauge parameters and programming bending sequences through CNC controls. Proper calibration is fundamental for producing components that meet exact design specifications.

Maintenance Guidelines for Construction Machinery Press Brakes

Regular Equipment Inspections

Inspection Process

Implement a comprehensive inspection protocol to identify potential wear or damage. Focus particularly on hydraulic system components and machine alignment to maintain consistent operational performance.

Proper Lubrication and Cleaning Procedures

Establish a systematic schedule for cleaning and lubricating moving parts, with special attention to ram guides and tooling interfaces where contaminants may accumulate.

Implementing Preventive Maintenance Plans

Develop a proactive maintenance strategy that includes regular checks of electrical connections, fastener tightness, and control system functionality to prevent potential operational issues.

Frequently Asked Questions

Calibration Best Practices for Press Brakes

Ensure proper calibration by verifying machine levelness and utilizing precision measurement tools to assess die bend angles. Follow manufacturer specifications for optimal calibration adjustments.

Recommended Maintenance Intervals

Conduct comprehensive maintenance checks every 500 operational hours, including thorough inspections, cleaning procedures, and lubrication of critical components to maintain peak performance.

Material Compatibility Considerations

Modern press brakes are capable of processing various high-strength materials, including advanced steel alloys, when equipped with appropriate tooling and configured with correct tonnage settings.

Final Thoughts

Press brakes represent a critical component in construction machinery manufacturing, facilitating the production of both structural elements and specialized components. Through proper configuration, operation, and maintenance practices, these machines can deliver exceptional performance and reliability. For additional technical support or detailed operational guidance, consult with industry experts or explore specialized technical resources.

By implementing these optimized practices and maintenance strategies, manufacturers can significantly enhance their production capabilities and operational efficiency in the construction machinery sector.