Revolutionizing Aerospace Manufacturing: The Transformative Impact of Advanced Press Brake Technology

The aerospace industry operates at the pinnacle of engineering precision, where micron-level accuracy can determine mission success. Modern press brake technology has emerged as a cornerstone in this demanding sector, enabling manufacturers to transform specialized alloys into the complex structural components that define contemporary aircraft design. This in-depth analysis explores how cutting-edge press brake solutions are addressing the unique challenges of aerospace manufacturing while setting new benchmarks for quality and efficiency.

Precision Engineering for Aerospace Excellence

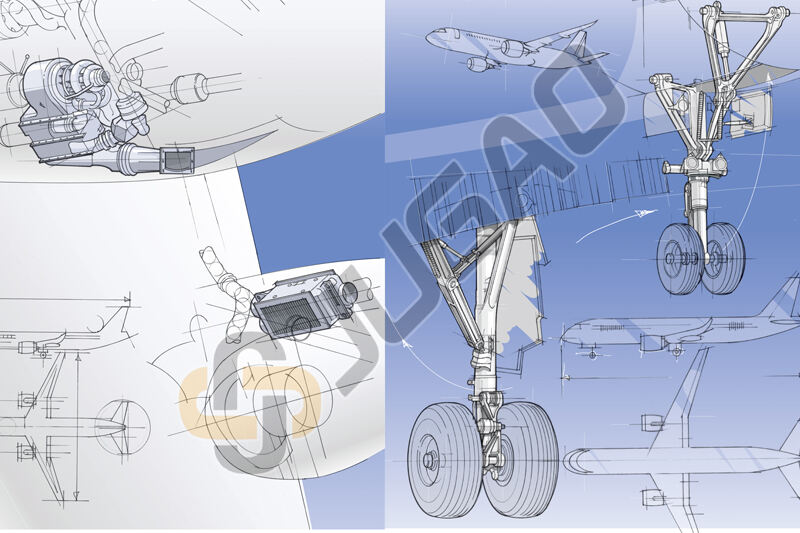

Fabricating Mission-Critical Aircraft Components

Aerospace applications demand unparalleled precision in metal forming operations. Today's CNC press brake systems deliver:

Structural airframe components with exacting dimensional tolerances

Precision-formed control surface assemblies

Engine compartment shielding elements

Landing gear structural elements

These advanced systems utilize real-time angle measurement and adaptive correction technologies to maintain tolerances within ±0.1°, ensuring perfect compatibility with adjacent aircraft systems.

Advanced Material Processing Capabilities

Modern press brake technology has evolved to handle aerospace-grade materials with exceptional finesse:

Titanium Alloys: Specialized tooling configurations prevent stress cracking

Aluminum Composites: Adaptive bending sequences accommodate material memory

High-Strength Steels: Precision-controlled hydraulic systems manage extreme material resistance

This material versatility enables manufacturers to optimize component weight without compromising structural integrity - a critical factor in aerospace design.

Streamlining High-Stakes Production Workflows

Contemporary press brake systems provide significant advantages in aerospace manufacturing environments:

Automated tool changing reduces setup time by up to 70%

Integrated vision systems verify component geometry in-process

Cloud-connected monitoring enables predictive maintenance scheduling

Digital twin technology facilitates rapid process optimization

These capabilities prove particularly valuable when producing complex wing and fuselage components where traditional fabrication methods would be prohibitively time-consuming.

Optimizing Press Brake Operations for Aerospace Standards

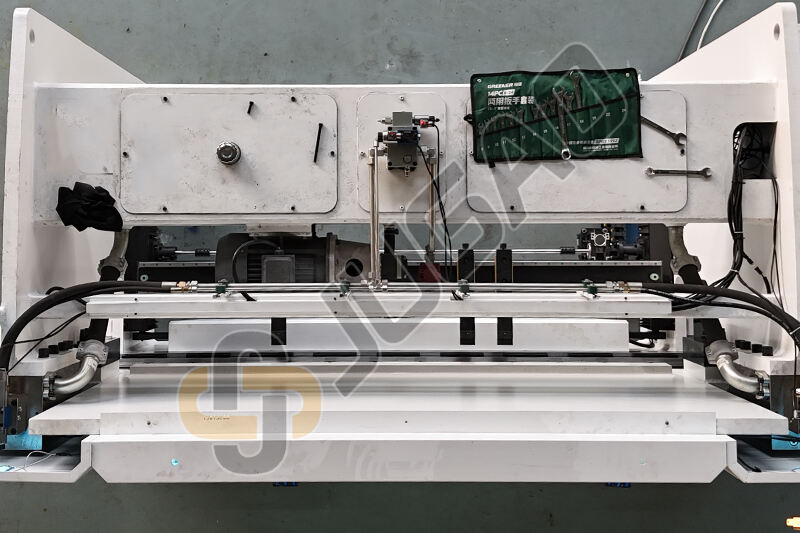

Strategic Machine Configuration Protocols

Establishing optimal press brake performance requires meticulous attention to setup procedures:

1. Workspace Preparation

-Vibration-dampened foundation installation

-Climate-controlled environment maintenance

Ergonomic operator positioning considerations

2. Precision Tooling Configuration

-Material-specific die selection protocols

-Laser-verified tool alignment procedures

-Dynamic pressure distribution optimization

3. Calibration Excellence

-Multi-axis backgauge certification

-Real-time angle monitoring implementation

-Automated compensation for thermal expansion

Comprehensive Maintenance for Peak Performance

Aerospace-grade maintenance protocols include:

Preventive Maintenance Schedule

-250-hour intermediate inspections

-500-hour comprehensive service intervals

-1000-hour full system recalibration

Advanced Diagnostic Procedures

-Hydraulic fluid spectrometry analysis

-Servo motor performance benchmarking

-Structural fatigue testing

Continuous Improvement Practices

-Software version control management

-Retrofit opportunity evaluation

-Operator skill enhancement programs

Expert Solutions for Aerospace Manufacturing Challenges

Q: What quality assurance measures ensure press brake precision in aerospace applications?

A: Implement a layered approach combining laser interferometer calibration, in-process CMM verification, and statistical process control methodologies.

Q: How does modern press brake technology address titanium's unique forming challenges?

A: Advanced systems utilize heated tooling options, strain-rate controlled bending sequences, and post-forming stress relief protocols to maintain material properties.

Q: What maintenance frequency is recommended for high-volume aerospace production?

A: Intensive operations require 200-hour inspection cycles with particular attention to hydraulic system integrity and guideway wear patterns.

Pushing the Boundaries of Aerospace Fabrication

The aerospace industry's relentless pursuit of performance excellence continues to drive press brake innovation. Emerging technologies such as:

AI-powered adaptive forming algorithms

Hybrid additive/subtractive manufacturing integration

Nanocomposite-compatible tooling systems

are positioning press brake technology as a key enabler for next-generation aircraft development. For manufacturers ready to elevate their aerospace fabrication capabilities, partnering with technology leaders who understand the unique demands of this sector can provide the competitive edge needed in today's market.

Leading equipment providers now offer comprehensive aerospace solutions packages, including:

Material-specific process development services

Regulatory compliance documentation support

Turnkey training and certification programs

By embracing these advanced capabilities, aerospace manufacturers can achieve unprecedented levels of precision, efficiency, and innovation in their metal forming operations.