Rolling Out Strong and Durable Steel Plates with Steel Plate Rolling Machine

Introduction:

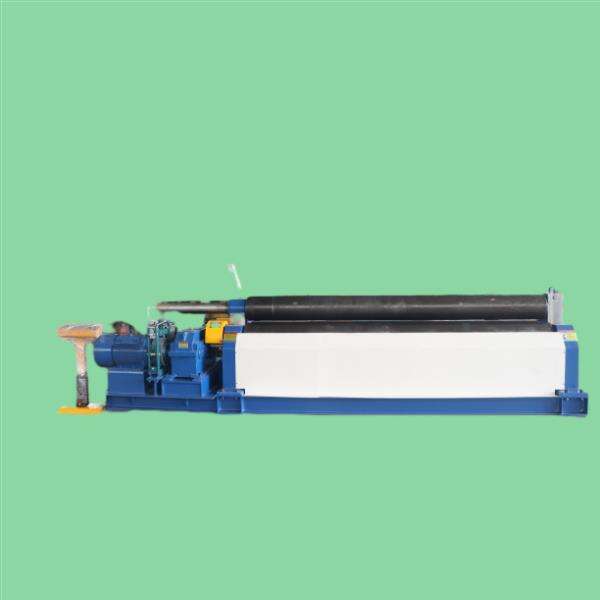

Are you looking for a machine that can produce high-quality and consistent steel plates? Look no further because the JUGAO steel plate rolling machine is here to roll out sheets of metal that are essential for construction, manufacturing, and other industries.

The steel plate rolling machine has several advantages that make it a popular choice for engineers and manufacturers. It has a high production speed, allows for precise cuts and measurements, and rolls out steel plates with a smooth surface and accurate thickness. Moreover, it has the ability to process different types of metals such as carbon steel, stainless steel, and aluminum. These advantages make the JUGAO plate rolling machine suitable for a wide range of industries, including construction, aviation, automotive, and shipbuilding.

With technological advancements, steel plate rolling machines continue to evolve to meet the changing needs of customers. The latest models come equipped with intelligent control systems, which enable operators to monitor the JUGAO metal rolling machine’s performance, adjust the settings, and detect any possible defects. Additionally, they have safety features such as emergency stop buttons and automatic shut-off mechanisms that prevent accidents and injuries.

Like any machine, the steel plate rolling machine can be risky if not handled carefully. Therefore, operators must undergo proper training on how to operate the machine and follow the manufacturer's safety guidelines. They should wear protective clothing such as gloves and safety glasses when working with the JUGAO rolling sheet metal. Additionally, it is crucial to keep the workspace clean and organized to prevent accidents.

The steel plate rolling machine is easy to use, even for those who are not familiar with it. To use the machine, operators need to load the metal sheet onto the rollers, adjust the settings, and press the start button. The JUGAO sheet rolling machine’s rollers will then compress the metal sheet, gradually forming it into a steel plate. Once the plate has been rolled out, it can be cut into the desired size and shape using other machines such as a laser cutter or a plasma cutter.

their precision efficacy laser cutting machines steel plate rolling machine range different materials. Rolling machines thanks excellent forming abilities efficient production meet needs many customers. Mass production requirements; Pipe Bending machines ideal variety pipe processing thanks flexible bending capabilities long-lasting performance. products embody essence latest industrial technology allow manufacturing industry tackle various challenges effectively, accurately flexibly.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed steel plate rolling machine cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective steel plate rolling machine production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

understand steel plate rolling machine RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

At some point, the steel plate rolling machine will need maintenance and repairs to ensure it operates at its best. Therefore, customers should choose a reputable manufacturer that offers comprehensive service and support. The manufacturer should provide installation, training, maintenance, and repair services to help customers maximize the JUGAO sheet metal rollers’ efficiency and minimize downtime.

The quality of steel plates produced by a rolling machine depends on several factors, including the quality of the machine, the type of metal being processed, and the skill of the operator. Therefore, customers must choose a high-quality JUGAO metal sheet roller that meets their needs and budget. They should also consider factors such as durability, accuracy, and reliability.

The steel plate rolling machine is used in various industries to produce steel plates with different thicknesses and shapes. For example, the construction industry uses steel plates in a JUGAO sheet metal rolling for building frames, bridges, and other structures. The aerospace industry uses steel plates for aircraft parts, while the automotive industry uses them for manufacturing cars and trucks. Similarly, the marine industry uses steel plates for shipbuilding, and the energy industry uses them for producing pipelines and other infrastructure.