Looking for a simple yet effective plus means safer join steel section together? Search no further than laser welding devices. Laser welding devices have actually revolutionized the way in which are genuine build plus fix steel components. We are going to talk about the many perks of JUGAO lazer welding machine, their innovation, security, utilize, provider, quality, plus application.

Laser welding devices provide a few importance over conventional welding techniques. First, laser welding devices enable exact control of the weld, causing a far more accurate and finish smooth. 2nd, laser welding machines is quicker than old-fashioned welding practices, reducing manufacturing some time expenses. Third, JUGAO laser welding devices may be used for the wider assortment of metals plus alloys, creating them versatile plus devices being efficient. 4th, laser welding equipment give you a small area which was heat-affected and thus the nearby steel just isn't afflicted with heat regarding the weld, reducing the possibility of warping as distortion into the item final.

The innovation of laser welding devices has resulted in their use wide in companies. Contemporary laser welding devices utilize computer-aided design (CAD) and production computer-aidedCAM) technology generate welds being accurate minimal mistake. Also, some JUGAO laser welding machines offering robot integration, enabling also greater accuracy plus persistence within the welding procedure.

Protection is often the priority top it comes down to utilizing just about any equipment. Laser welding devices is safer to utilize if best precautions is taken. Operators should put gear protective such as for example goggles plus gloves, to avoid presence to your laser. Furthermore, JUGAO laser welding devices should be run in well-ventilated areas to avoid the risk of inhaling fumes being toxic particles. It is vital to follow all security instructions plus directions when working with the laser welding device.

Making use of laser welding devices might appear daunting, however it is really an activity simple. First, the steel section become welded needs to be precisely served by cleansing plus aligning them. Next, the laser welding device must be correctly arranged by adjusting the charged pulse plus energy settings to complement the depth plus form of steel being welded. Finally, the JUGAO laser weld machine price are directed at the steel components to additionally feel accompanied the welding procedure starts. It is vital to exercise on scrap steel before welding an item make certain that was real appropriate weld plus minimize any errors.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales laser welding machines well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.

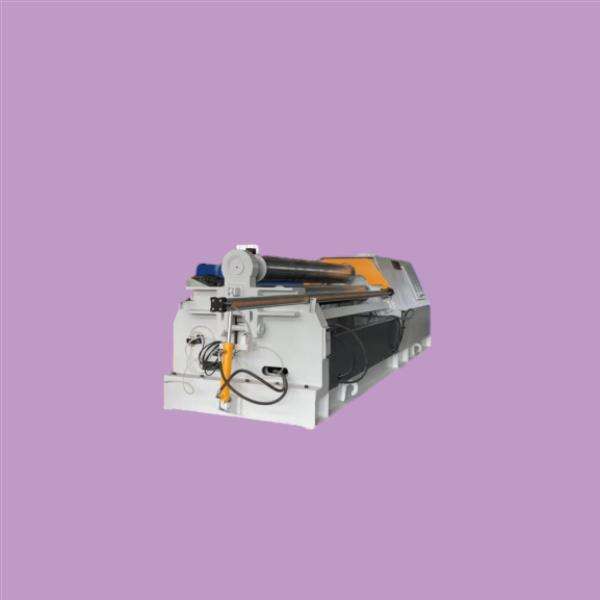

Press brakes ideal laser welding machines tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

laser welding machines specialize metal sheet forming high-quality production. Pipe Bending Machines flexible solutions pipe bending. product line focused efficiency, accuracy, stability, allows customers increase production efficiency improve quality products.

Quality Builds laser welding machines: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.