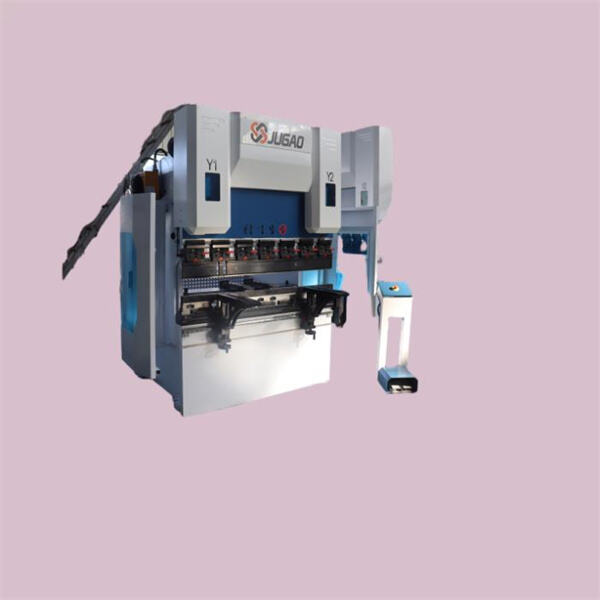

Introduction:Ever heard of a metal bending machine that could flex some tough and hard metals in minutes? It is a hydraulic press brake bending machine, an amazing tool It is a powerful and versatile device used to forge metal with accuracy. Deep dive into the interesting world of this machine and unveil how it has changed metal fabrication & manufacturing.

Hydraulic Press Brake - That Lets You Bend the Metals into Desired Angles and Forms The machine uses hydraulic cylinders, which work like giant syringes filled with oil or water and apply pressure in a controlled way to the die --a specialized metallic tool that gives shape. The die then forces the metal into a second die (a flat surface), or more commonly, against another V-shaped punch. This adjustment is fine tuned by the die set, often using computerized controls which will allow even greater precision in depth and length of bending to create the desired 3D shape.

Newer versions of hydraulic press brakes (back gages are mechanical or electronic devices that check the placement and change position for sheet metal with respect to dies) including state-of-the-art technologies. The thickness and curvature of the metal is also detected using laser sensors, further improving bending accuracy. This configuration, combined with advanced software algorithms to improve the bending order and eliminate errors optimize the overall speed, efficiency and accuracy of bend operations. As a result, the risk of waste material misuse and rework is minimized along with fewer chances for workplace injuries.

Metal fabrication is no different in the sense that time equals money. One of the primary goals are to achieve the highest productivity and least amount of downtime, setup up or maintainance possible. The capability of a hydraulic press brake can function as the driving force for your business in meeting these objectives by streamlining workflows and improving manufacturing efficiencies. For example, long sheets of metal can execute a series or bends by operators using this machine and they might not need multiple tools/ machines. Moreover, when bending is harmoniously combined with associated operations like cutting, punching or welding to create a material flow strategy that in turn reduces the use of manual handling and transportation. Computer controls that store and recall settings for different products or projects allow operators to switch tasks without compromise of quality/care.

Not only is it a versatile tool for industrial applications, but an hydraulic press brake has opened up whole new creative worlds to the artisan and craftsman. This machine enables the home-gamer and industrial workshop owners alike to embark on their respective creative passion projects -- limited by only metal! It means moving from the realm of artistic sculpture, bespoke furniture making and production of customized accessories reflecting individual skills and aesthetics taking advantage of precision operation versatility only a hydraulic press brake can offer. Experimenting with materials means being able to play around not only with texture but also color and finishes, from aluminum or stainless steel to even brass or copper. Artisans can just as easily push their boundaries, branching into entirely-new territories to make ideas without limits with the benefit of a hydraulic press brake.

Ways You Can Do To Deserve The Uses Of A Hydraulic Press Brake In Your Enterprise

A quality hydraulic press brake bending machine can revolutionize the processes of metalworking entrepreneurs and businesses. It is critical to innovate and improve efficiency in a competitive market when facing changes dictated by the market, regulatory environment or expectations from customers all while cost pressures are increasing. When businesses invest in the best new equipment including a top-tier hydraulic press brake, they will get on track to see those stellar growth results in full. This machine maximizes both quality and precision in the production of parts/products, while reducing material wastage as well as labor costs. Likewise, expanding the product range apart from presenting tailor-made services to customers have the capacity in getting a good reputation and gain more trust coming from potential buyers. Adopting a hydraulic press brake leads to safety and sustainability enhancements by reducing noise, emissions, as well is eliminating risks related with alternative bending techniques. In short, the implementation of a premium-quality hydraulic press brake in operations leads to better days ahead for businesses as well their workforce.

To sum it up, the hydraulic press brake bending machine is far more than a toy that can crush crops or phone mats. It comes into being as an asset of a device that is driving creativity and productivity in the metal fabrication, manufacturing. Whether you are a hobbyist, seasoned professional or an up-and-coming entrepreneur the speed and efficiency of using a hydraulic press brake will always give your metalworking new directions it can take simply by being quicker and safer. Then why wait, come go to realize the numerous possibilities over this beast of a machine and take bending game to next level with it.

Rolling Machines specialize metal sheet forming high-quality production. hydraulic press brake bending machine offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

hydraulic press brake bending machine Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

hydraulic press brake bending machine aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle hydraulic press brake bending machine materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.