Benefits of a 600-Ton Press Brake for Bending on Large Scale

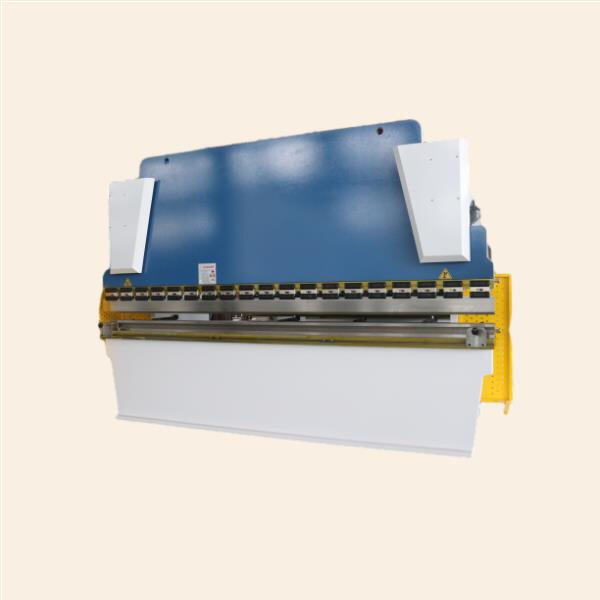

A 600-ton press brake is a strong and robust machine typically found in the industrial sector, primarily used to fold metal sheets for heavy projects. Here are the most important advantages of using a 600-ton press brake for high-volume bending jobs:

1. Enhanced Bending Capacity

The first and foremost benefit getting a 600-ton press brake consists of its large ability for bending. This machine is capable of bending thicker sheets a great deal faster and as such has started to become more popular in larger projects where time could be deemed an issue.

A machine like this one can give you a level of precision in your bending that the competition just wouldn't be able to compete with. This higher capacity allows each bend to be executed correctly, significantly reducing errors. As a result, the final products will be of best quality and quite uniform as compared to what is usually produced out smaller press brakes.

3. Heightened Safety Measures

It is even safer to operate a 600-ton press brake than working with smaller machines; The hydraulic and computer-controlled technology gives the operator a high level of control over bending with minimal chance for accidents or injury.

4. Time and Cost Efficiency

A 600-ton press brake can bend heavier and thicker pieces of materials easier than other machines, making it an ideal machine for large scale bending projects. This is clearly very efficient as it save a significant amount of time and costs during production, allowing more focus from the business end to other areas.

5. Versatility in Application

A 600-ton press brake is so versatile, it can be adapted to bend a wide range of projects. Its flexibility in terms of the allowed shapes, material thicknesses and size makes it a useful device for every type of manufacturing.

How to Choose The Right 600-Ton Brake Press For Your Needs

Selecting the Correct 600-Ton Press Brake for Your Operation So when making decisions about what to buy, consider these brain-imaging-based insights:

1. Compatibility of Materials and Thickness

Make certain that the press brake you choose is ideal for the level of material and thickness required by your produtcions.

Take the bending bed length into account, depending on what material will be processed.

The tonnage of the machine also plays a very important part in this respect, and a 600-ton press brake is well suited for heavy-duty work like bending thick plates.

Look for such features as automatic tool change and computer control technology that will speed up the bending process, making your work easier.

Levels Of Material Capabilities of a 600-Ton Press Brake With Different Tools

A 600-ton press brake is a beast in terms of archival ability. Specializing in aluminum, stainless steel & mild steel this machine has you covered. In tandem, the array of tooling options means that it can handle different shapes and sizes ensuring its importance within manufacturing.

Latest Technology: ACCURL 600-Ton Press Brake Is Always High-quality,power Efficient, Precise Bending

With technology advancements for a 600-ton press brake, precision metal bending is no longer met by its machinists. Features such as computer control, an automatic tool changer improves the reliability and accuracy of bending.

Select The Best 600-Ton Press Brake

The choice between the different models of 600-ton press brake that are available is an important one for your operations. Amada, Axial Bystronic and LVD similarly offer high-quality machines with advanced features at competitive prices. Take your time to conduct research in order that you may select the brand which best aligns with how you operate.

In conclusion, 600 ton press brake is an innovative method of creating unimpeachable precision. Properly choosing the machine that fits your needs correctly, guarantees better performance and commitment to achieve success. As technology progresses, the possibilities for high-quality bending projects are endless with the 600-ton Press Brake consolidating itself as a fixture in manufacturing environments.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market 600 ton press brake using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle 600 ton press brake materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.

understand 600 ton press brake RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Rolling Machines specialize metal sheet forming high-quality production. 600 ton press brake offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.