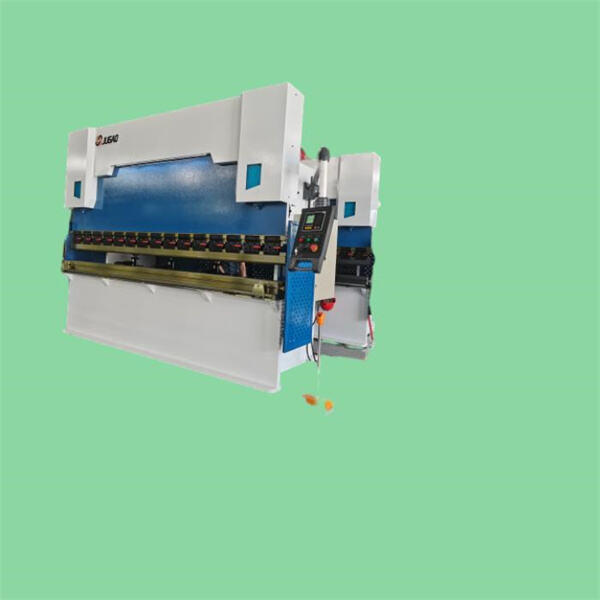

Sheet and plate metal are often bent, formed or shaped as part of this process, but it is ideally done with the right tools whose quality them an easy fit for countless projects. A 100 ton press brake is a standalone device that bends metal well, and it does so exceptionally. Today we are going to discuss top 5 sheet metal brake press products which work best with our Sheet Metal Machines for all ranges Newest The Best Hydraulic Press Brake, US built machines gangyangara.

Accurpress 100Ton Press Brake: This particular Accupress model is famous as it can make high-quality bends and for material lengths of fourteen feet with precise.

ROBOT PRESS BRAKE 100 Ton JMT Press Brake: With Y1-Y2 designed hydraulic cylinders, which are especially useful in bending of complex curves and arcs as the cylinder synchronization makes it safer.

100 Ton Cincinnati Press Brake 11 - This press brake has been introduced with a never-seen-before multi-axis control system that encompasses every aspect of bending operations, thereby enhancing its ability to produce much more challenging rolls and bends.

The utility solidified casing and ram are structured as one piece giving the Pacific 100 Ton Press Brake its solidarity getting exactness gauges long life expectancy connections to our high-power water powered arrangement.

100 Ton Amada Press Brake: It allows automation of complex bending with the combined use mechanical, hydraulic and servo-electric technologies that make this multipurpose press brake a guarantee for accurate bends every time.

A 100-ton press brake with improved tonnage options open up new design possibilities for seasoned operators to cycle through more complex metal bending processes faster. Just as with any device, this equipment needs to be maintained and calibrated periodically so that it remains in proper working condition. They can be programmed and eventually automate the tool change, aiding in their manufacturing productivity.

Some of the advantages you will get when a 100 ton press brake is present in your workshop are;

The components of the unit feature a trustworthy hydraulic system performance engineered to keep your metal materials intact and premium in quality.

Options for A Variety of Bending Applications: Folding Thin Sheets to Heavy Plates

Productivity Improvement: A qualified press brake operator can reduce manual work and thus increase manpower productivity by twenty percent, which in turn improves manufacturing efficiency.

Read further on this topic: What parts you can have added or controlled to eliminate any more of that unpredictability from your press brake and help increase productivity in a safe manner like safety light curtains, back gauges & a PC console. Due to the fact that press brakes play a vital role in many metalworking operations-needing proper maintenance, training and calibration for maximum performance and service life, your manufacturing depends on them.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed 100 ton press brake cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

100 ton press brake Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

recognize significance RD 100 ton press brake. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

Press brakes ideal 100 ton press brake tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.