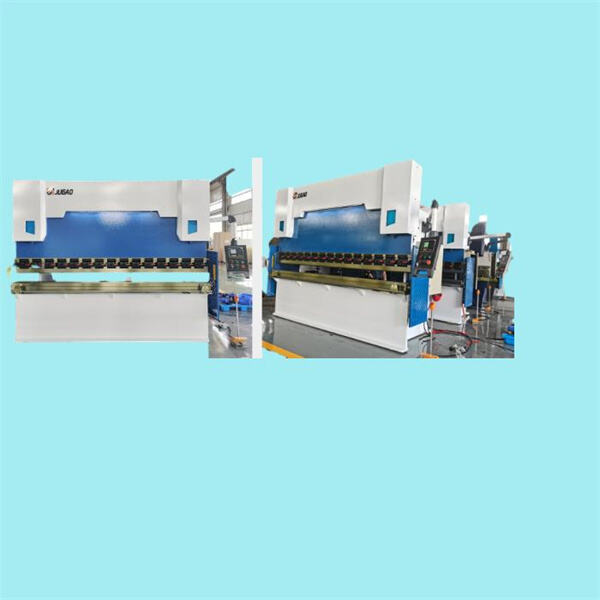

A 20 ton press brake is one of the staple machines found in metal fabrication shops, and plays an important role in bending, shaping, and cutting metal sheets with accuracy. This machine is popular throughout a range of industries, from small to large due in part because it can work with different types of materials including steel, stainless steel, aluminum and brass.

The Baileigh BB-2014E, the Edwards HAT2010 and JET J-Press 20 are among the top-rated 20 ton press brake machines which gives precision bending. These are the machines that have made a name in this industry for being good.

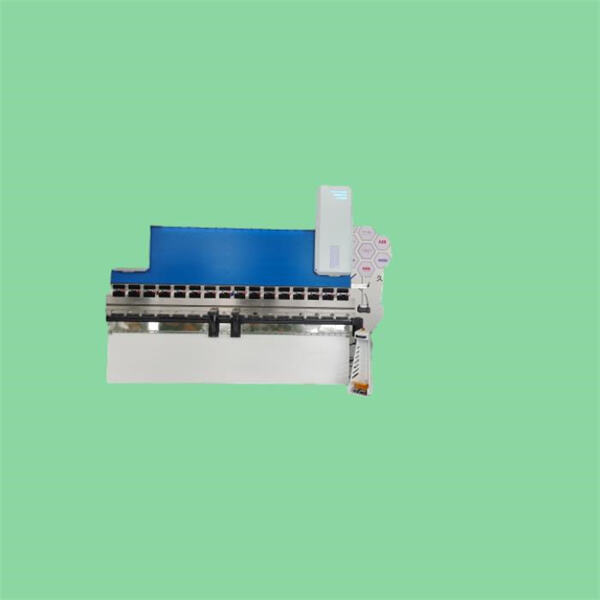

In addition to boasting a maximum 20-gauge mild steel sheet bending capacity, Baileigh BB-2014E Hydraulic Press Brake is also considered THE hydraulic press brake of all time. It comes with a rugged fully welded steel frame for ultimate strength and ensures it lasts over many years of precise bending. This machine has back gauge and hydraulic cylinder - With 14 inch bending length, this is a basic feature comply with others.

One more significant machine is Edwards HAT2010, a model that manages the bending pressure by hydraulic devices and bends 10 gauge mild steel easily. It is a popular choice for those looking to achieve precision in their bending projects with its 20-inch bending length complemented by features such as: Finger brake, Back gauge, and Variable speed control.

The other widely praised hydraulic press brake, the JET J-Press 20 offers a 20-tonne rating and bent length of just over half-a-metre. This machine capacity to handle bending duties of up-to 10 gauge mild steel is enough for precise bends and further, it also features a hydraulic cylinder along with a back-gauge & foot pedal control

When choosing the proper 20 ton press brake for your workshop, you need to take a few factors into account. You should always consider what sizes of material you are working with, the parameters and accessories each machine offers as well as its physical dimensions.

Another crucial consideration is what size and the type or material you will be bending. A higher capacity is only needed if you are working with thicker or more difficult to cut materials a lot. Also, if you are working with metal sheets which have a larger length, it is recommended to buy bending machine with longer bending length.

Additionally, the actual size of the machine should fit within your workshop. Short of space: Smaller workshops may benefit from a compact machine that can be easily manhandled (a larger workshop will house bulkier equipment)

Lastly, consider which features and accessories that come with the machine. While some press brakes include convenient features like a back gauge and foot pedal control for increased operational efficiency, others provide extra accessories such as custom dies or specialized tooling.

To ensure safety when running a 20 ton press brake, necessary precautions which must be taken include using eyewear and gloves for protection, grounding the machine properly if need be and servicing it regularly. Steps include cleaning, lubricating and checking hydraulic fluid levels-and inspecting for signs of wear or damage to maintain the machine in top performance.

When it comes to reliable 20 ton press brake models, the three best picks are: Baileigh BB-2014E Edwards HAT2010 JET J-Produce 20 Their durability and reliability is credited to the tough construction of these machines as well as their precise bending abilities and easily- operated features.

Taking time to utilize the advanced features that are built into your 20MT press brake can really help increase performance. Explore fully programmable CNC controls, multi-axis back gauges and other tailored tooling options to reduce trimming in-between bending. In some machines, there are additional features that can be used to enhance the precision and accuracy of bending jobs: from laser alignmentdevices or variable speed controls.

In summary, 20 ton press brake is an essential equipment to have in a metal fabricating workshop and by choosing the right machine you will be able to use it for many years making sure that it stays operative!

Quality Builds Trust. We committed sheet metal machinery assure every machine sell up industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease worries.able 20 ton press brake quickly market needs utilizing efficient production supply-chain management. ample inventory, delivery times cut just week, allows rapid acquisition equipment gaining market advantage.

know importance service sales RD 20 ton press brake. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe 20 ton press brake. product range focused efficiency, precision, stability help customers improve production efficiency quality products.

precision efficiency, 20 ton press brake cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.