What Materials Can Be Cut with a Fiber Laser?

As a leader in cutting-edge technology, we often get asked, “What materials

can be cut with a fiber laser?” Fiber laser cutting is transforming industries

by offering unprecedented precision and efficiency. Fiber lasers are adept at

processing a variety of materials, including metals like stainless steel, carbon

steel, alloy steel, iron, copper, aluminum, and titanium alloys, as well as

plastics and even wood. They consistently deliver clean and precise cuts, with

the added benefit of not requiring secondary processing for smooth finishes. In

this article, I’ll walk you through the various materials that can be cut using

fiber laser technology and explain why this method is becoming the go-to

solution for manufacturers worldwide. Let’s dive into the incredible versatility

of fiber laser cutting.

Finding it challenging to select the appropriate cutting method for varying materials? Opting for the incorrect cutting tool may result in unsatisfactory outcomes and unnecessary resource consumption. Fortunately, fiber lasers offer a versatile and efficient solution for a wide range of materials.

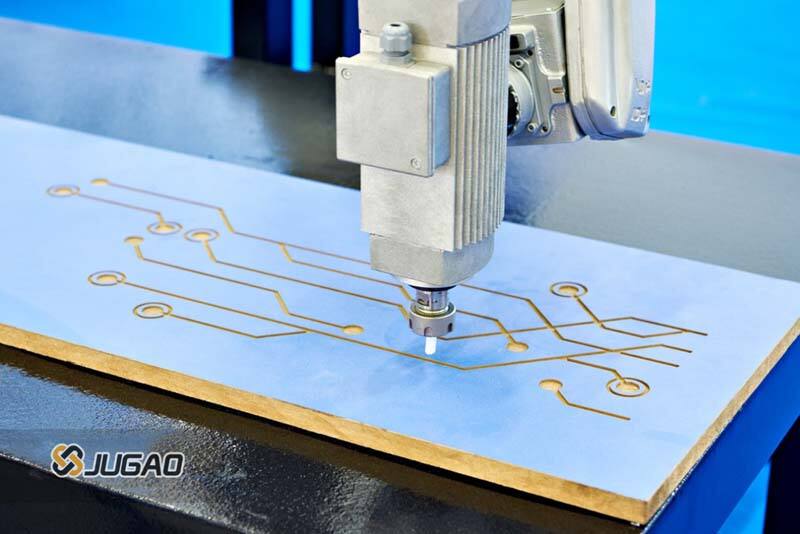

Fiber lasers are renowned for their precision and efficiency in cutting a wide range of materials, including metals, plastics, and composites. For instance, precision can be guaranteed to 0.01mm/step with an overall accuracy error within ±0.5mm, as tested during the quality assurance process. Moreover, fiber laser cutting machines can achieve a cutting precision of ±0.015mm with a repeatability of ±0.001mm, making them ideal for high-precision applications such as medical devices and microelectronics. Their advanced technology makes them ideal for industries requiring accuracy and speed. Let’s explore which materials work best with fiber lasers and why they are the preferred choice for many manufacturers.

What is Fiber Laser Cutting?

Fiber laser cutting involves using a laser beam generated by a fiber optic laser to melt or vaporize material, resulting in precise cuts. This cutting process uses a high-intensity beam that is focused onto the material’s surface. Fiber lasers are known for their excellent beam quality, high power output, and ability to cut through thicker materials with less distortion.

Fiber lasers, which utilize a solid-state medium, offer significant advantages over traditional CO2 lasers by being more energy-efficient, compact, and faster in operation. The high-speed capabilities and precision of fiber laser cutting, as demonstrated by machines such as the 1500W fiber laser cutting machine with a cutting speed of 100m/min, are particularly advantageous for applications that demand intricate cuts, clean edges, and minimal heat-affected zones.

Introduction to Fiber Laser Technology

Fiber laser technology represents a cutting-edge advancement in the world of industrial lasers, offering remarkable precision, efficiency, and versatility. Fiber lasers, unlike traditional CO₂ lasers or solid-state lasers, utilize a laser beam that is generated through a fiber-optic cable composed of glass or other specialized materials. This approach allows for higher efficiency and lower maintenance compared to CO₂ lasers, as fiber lasers can achieve a higher photoelectric conversion rate of up to 30%, significantly reducing energy consumption and operational costs. These lasers offer numerous advantages, particularly in applications requiring fine cuts, deep engraving, or high-speed processing.

Fiber lasers are increasingly recognized as the preferred technology across a multitude of industries, such as metalworking, automotive, aerospace, and medical device manufacturing, due to their superior beam quality, stability, and flexibility in power and wavelength. Below is an introduction to the core principles of fiber laser technology, its components, working mechanism, and advantages.

What Materials Can Be Cut with a Fiber Laser?

Fiber lasers have become an indispensable tool in the metal cutting industry, rapidly replacing traditional metal processing methods. They are capable of cutting metal sheet with high precision and efficiency, often three times faster than other cutting methods. The use of fiber lasers allows for automatic focusing, which is crucial for cutting different materials, and the 'leapfrog' function, which significantly reduces the time required for the cutting head to move, thus increasing overall efficiency. Additionally, fiber lasers can cut through thick metal plate with ease, and their use of cooling systems like laser chillers ensures stable cutting quality and efficiency.

Indeed, fiber lasers are highly efficient and widely adopted for metal cutting in industrial settings, known for their precision, speed, and cost-effectiveness. Fiber lasers are highly effective for cutting a variety of metals due to their precision, speed, and energy efficiency.

Versatility Across Metal Types

1. Stainless Steel

Stainless steel is one of the most commonly cut materials using fiber lasers. The laser beam's high-energy density allows for exceptionally precise and clean cuts, producing smooth edges even on the thinnest sheets.

Applications include: Kitchen equipment, Medical devices, Automotive parts, Architectural components

2. Carbon Steel

Fiber lasers excel in cutting carbon steel, offering fast cutting speeds and high-quality results. With oxygen-assisted cutting, thicker carbon steel sheets can also be processed efficiently.

This makes fiber lasers invaluable for: Construction equipment, Heavy machinery manufacturing, Industrial piping

3. Aluminum

Aluminum’s lightweight and reflective properties make it a popular material in industries like aerospace and automotive. Modern fiber lasers, equipped with anti-reflective technology, can easily cut aluminum with excellent precision and minimal heat distortion.

Key applications include: Aircraft parts, Automotive panels, Consumer electronics

4. Copper

Copper, known for its high reflectivity and conductivity, presents difficulties for conventional cutting techniques. Advanced fiber lasers are capable of efficiently cutting copper, ensuring clean edges and preventing warping, due to their high absorption of light by the material and the use of auxiliary gases that enhance the cutting process.

Its common applications encompass electrical components, plumbing fixtures, and decorative items.

5. Brass

Like copper, brass possesses reflective properties yet can be accurately cut using a fiber laser. The precise control of heat ensures that the material retains its aesthetic appeal without tarnishing.

Industries using brass components include: Musical instruments, Jewelry design, Decorative hardware

6. Titanium

Titanium is a strong, lightweight metal often used in high-performance applications. Fiber lasers can handle titanium’s strength and hardness, producing precise cuts without compromising material integrity.

Typical applications are: Aerospace components, Medical implants, High-end sports equipment

Advantages of Fiber Lasers for Metal Cutting

1. High Precision and Clean Cuts

Fiber lasers produce a focused, high-energy beam that enables extremely precise and clean cuts. This makes them ideal for industries that require intricate designs and tight tolerances.

2. Cutting Thin and Thick Metals

·Thin metals can be cut at high speeds with minimal thermal deformation.

Fiber lasers with higher power (e.g. 6 kW or above) can easily cut thick metals.

3. Energy Efficiency

In comparison to CO₂ lasers, fiber lasers offer reduced energy consumption and enhanced cutting efficiency, as evidenced by their ability to match the cutting效能 of a 4kw CO₂ Laser with only 3kw of power.

4. Low Maintenance

Fiber lasers have fewer moving parts and a solid-state design, resulting in reduced maintenance requirements and longer operational lifespans.

Can Fiber Lasers Cut Non-Metal Materials?

Fiber lasers are primarily intended for metal cutting and processing, yet they possess the capability to manage select non-metal materials, albeit under specific conditions. Nonetheless, their efficacy in dealing with non-metals is typically constrained when juxtaposed with CO₂ lasers, which excel in these applications owing to their extended wavelength and enhanced absorption by non-metal substances. Here’s a detailed overview of what fiber lasers can and cannot cut in the realm of non-metal materials.

Non-Metal Materials Fiber Lasers Can Cut or Process

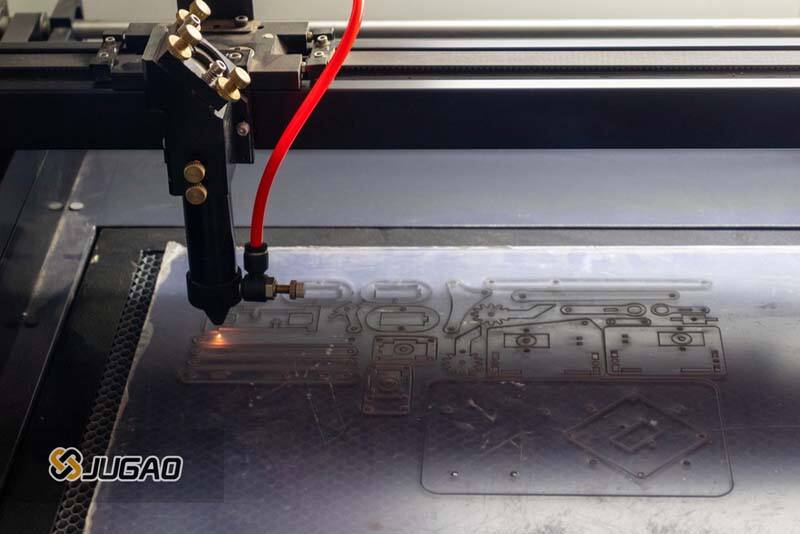

1. Plastics

Fiber lasers can mark and engrave various plastics but are not ideal for cutting thick plastic sheets. Thin layers of plastic or specialized plastics (e.g., polycarbonate or acrylic) can sometimes be cut with lower-powered fiber lasers, but the quality may vary.

Applications: Labels, barcodes, branding, and custom designs.

2. Ceramics

Fiber lasers are frequently employed for marking or surface etching ceramics, rather than for cutting purposes. The high precision of fiber lasers allows for detailed designs on ceramic surfaces without compromising the material’s integrity.

Applications include industrial components, decorative items, as well as medical equipment.

3. Glass

Fiber lasers are unsuitable for cutting glass, but they can mark or engrave it when used in conjunction with specific laser parameters or coatings.

Applications: Branding on glass bottles, artistic engravings, and industrial markings.

4. Composites

Thin composite materials may be cut or marked, but fiber lasers may struggle with thicker, layered composites due to uneven heat absorption.

Applications: Aerospace and automotive components, or lightweight structures.

5. Rubber

Fiber lasers can mark and engrave rubber efficiently, making them suitable for creating intricate designs or text. Cutting rubber is possible but not commonly done with fiber lasers.

Applications: Stamps, gaskets, and seals.

Non-Metal Materials Fiber Lasers Struggle With

Wood

Fiber lasers are not well-suited for cutting or engraving wood due to their short wavelength, which is poorly absorbed by organic materials. CO₂ lasers are more effective for wood processing.

2. Fiber lasers often burn or damage fabrics because of uneven heat distribution. CO₂ lasers are favored for precise cutting and engraving of textiles.

3. Fabric and Textiles

Fiber lasers generally burn or damage fabrics due to uneven heat distribution. CO₂ lasers are preferred for clean cutting and engraving of textiles.

4. Fiber lasers have difficulty cutting foam materials effectively due to melting and uneven cuts.

5. Paper and Cardboard

Fiber lasers are not ideal for these materials due to excessive heat and risk of ignition.

Why Fiber Lasers Are Limited for Non-Metal Materials

· Wavelength: Fiber lasers operate at a wavelength of 1.064 microns, which is ideal for metals but not absorbed efficiently by many non-metals.

· Heat Control: Non-metals often absorb and distribute heat unevenly, leading to burns, warping, or melting.

· Material-Specific Properties: Organic and porous materials, such as wood or foam, do not interact well with the intense, focused beam of fiber lasers.

Alternative for Non-Metals: CO₂ Lasers

In industries that necessitate extensive non-metal cutting, such as woodworking and textile manufacturing, CO₂ lasers have proven to be the superior option. They operate at a longer wavelength (10.6 microns) that interacts well with non-metal materials, providing cleaner cuts and more versatility.

Alternative for Non-Metals: CO₂ Lasers

For industries that require extensive non-metal cutting (e.g., woodworking, textile manufacturing), CO₂ lasers are the better choice. They operate at a longer wavelength (10.6 microns) that interacts well with non-metal materials, providing cleaner cuts and more versatility.

Factors That Affect Fiber Laser Cutting

Several factors influence the efficiency and quality of fiber laser cutting:

· Material Thickness: The thickness of the material plays a crucial role in determining the cutting speed and laser power required. Thicker materials generally require higher laser power and slower cutting speeds.

· Material Reflectivity: Certain materials, including aluminum and copper, exhibit high reflectivity that can impede laser cutting processes. However, fiber lasers are particularly adept at cutting reflective metals, outperforming CO2 lasers in this task.

· Laser Power and Cutting Speed: The power of the laser and the cutting speed determine the quality and efficiency of the cut. Higher power typically results in faster cutting, but can also increase the risk of burn marks if not properly managed.

· Gas Assist Types: The type of assist gas, particularly oxygen, used in fiber laser cutting can significantly affect the quality of the cut and the materials that can be processed, as evidenced by a study showing that oxygen as an assist gas led to a 38.1 mm s⁻¹ cut rate and improved cut quality for Nitinol.

Conclusion

Fiber laser cutting technology is capable of processing a wide range of materials, from metals to non-metals and composites. Its precision, speed, and versatility make it an invaluable tool in various industries. As fiber laser technology continues to evolve, the materials it can cut will expand, offering even more possibilities for manufacturers and fabricators.

About Gary Olson

Gary Olson is a skilled website editor at JUGAO CNC MACHINE, specializing in curating and organizing professional knowledge about sheet metal processing. With his keen eye for detail and unwavering passion for precision, he guarantees the accuracy, engagement, and informativeness of all technical content. Gary Olson regularly updates the JUGAO website with invaluable industry insights, helping to educate and support customers and professionals in the metalworking field. His dedication to excellence plays a key role in strengthening JUGAO's online presence and reputation as a trusted authority in sheet metal solutions.View all posts by Gary Olson