- Overview

- Inquiry

- Related Products

- Product Details

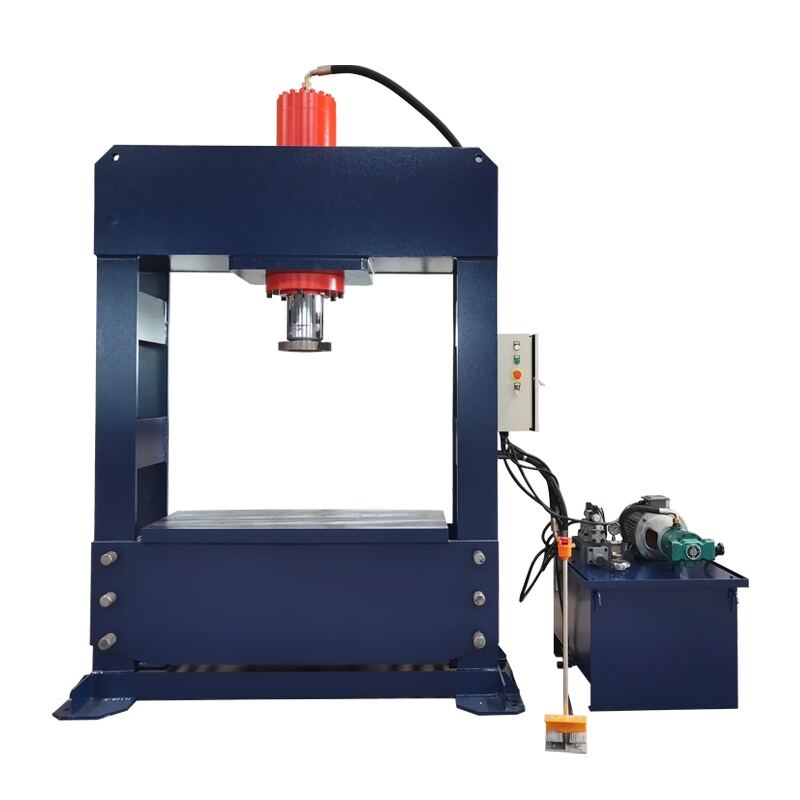

Single Column C Frame Hydraulic Press Machine

Product Features

Y41 series single calibration mounting hydraulic press is a multi-functional medium and small type of hydraulic press. It is suitable for shaft parts and other steel material or for press-assembly sleeve or bush parts. It also can be used to press powder or plastic parts with rough press requirements .

1. Totally European design, Welded steel frame rigid to deflection moment and high tensile with ST44 A1 materia .

2. Fully enclosed drive, easily accessible for maintenance, eliminates, exposed over hanging parts,slide and bolster tables with T-slots .

3. Uses a variable flow piston pump - offers high pressure resistance, high velocity, durability and low noise .

4. Hydraulic pipe system uses integrated circuits - manifold block fits inside the press to reduce piping and oil leaks, easy to maintain, simple and safe. Hydraulic system is from Bosch,Germany .

5.Guiding device: adopts four cylindrical location guiding to make sure of the steady precision, and it's easy to test and maintain .

6.Presses operated with automatic one cycle design; two hand push button design for simple and safe operation. Presses which could realize three-operation mode: adjustment, manual and semi-automatic .

7.PLC press control is flexible and safe. Adjustable proximity switches allows stroke adjustments in seconds .

8. The Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA .

Technical parameter

| Y41 | Unit | Y41-20T | Y41-30T | Y41-40T | Y41-60T | Y41-80T | Y41-100T | |||

| Nominal Pressure | KN | 200 | 300 | 400 | 600 | 800 | 1000 | |||

| Hydraulic Cushion | Capacity | KN | 800 | 100 | 120 | 150 | 350 | 400 | ||

| (Optional) | Stroke | mm | 120 | 120 | 120 | 140 | 150 | 150 | ||

| Max.Pressure | Map | 12.8 | 16 | 22.2 | 24.3 | 25.8 | 25.8 | |||

| Max.Opening Height | mm | 500 | 550 | 600 | 630 | 720 | 800 | |||

| Slide Stroke | mm | 350 | 350 | 400 | 500 | 500 | 500 | |||

| Accuracy Error Range Between Tables | mm | ±0 | .01 | |||||||

| Speed of Slide | Return Speed | mm/sec | 70 | 75 | 70 | 80 | 80 | 80 | ||

| Working Speed | mm/sec | 5~8 | 10~15 | 4~8 | 8~10 | 4~6 | 8~12 | |||

| Advance Speed | mm/sec | 55 | 50 | 55 | 65 | 60 | 65 | |||

| Throat depth | mm | 280 | 300 | 320 | 350 | 350 | 350 | |||

| Dimensions of Die Table | F.B. | mm | 500 | 500 | 550 | 620 | 650 | 650 | ||

| LR | mm | 600 | 600 | 700 | 700 | 700 | 800 | |||

| Ram Table Dimensions | F.B. | mm | 350 | 350 | 380 | 450 | 450 | 480 | ||

| LR | mm | 450 | 450 | 500 | 500 | 550 | 600 | |||

| Worktable Height | mm | 710 | 710 | 710 | 720 | 730 | 730 | |||

| Work Table Opening Diameter | mm | Φ100 | Φ100 | Φ100 | Φ140 | Φ150 | Φ150 | |||

| Hydraulic cylinder diameter | mm | Φ125 | Φ140 | Φ150 | Φ180 | Φ200 | Φ250 | |||

| Motor Power | KW | 4 | 4 | 5.5 | 7.5 | 7.5 | 7.5 | |||

| Overall Dimension | LR. | mm | 1050 | 1100 | 1250 | 1450 | 1500 | 1550 | ||

| F.B | mm | 650 | 650 | 780 | 800 | 950 | 1050 | |||

| Height | mm | 2100 | 2150 | 2300 | 2500 | 2560 | 2800 | |||

| Machine Weight | Kgs | 1700 | 2200 | 3100 | 4600 | 5300 | 6800 | |||