Safety solution for bending machine

1. Italian imported anti-pressure hand laser safety protection device MSD

----------More than 40 years of European technology accumulation has made it unique

Bending machine safety solutions

MSD laser protection avoids the danger of bending machine operators due to the rapid movement of the beam on the machine tool.

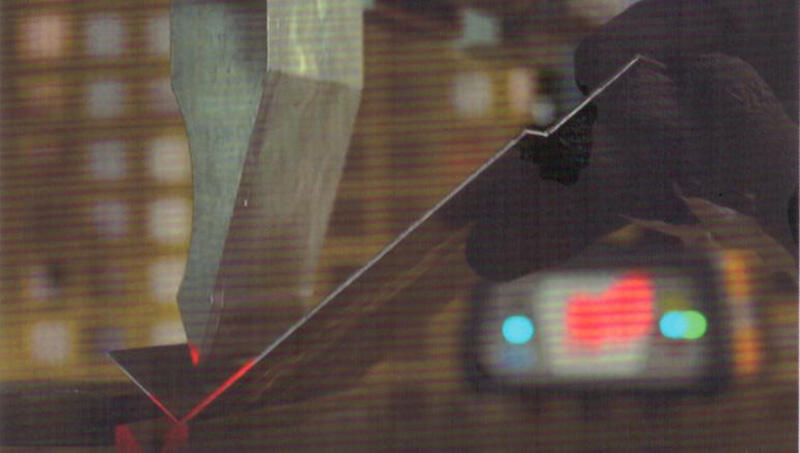

A single beam of visible laser is emitted from the transmitter, and the receiver receives the emitted beam, thus generating a detection area formed by a laser beam and acting on the entire bending axis. If any opaque obstruction enters the area and interrupts the laser beam, MSD will immediately interrupt the signal and stop the operation of the equipment through the control system.

Features:

*CLASS 1M laser transmitter that is harmless to human eyes

*The receiver is equipped with LED indicator lights to display various working modes

*Safety level reaches CAT.4 and SIL.3, protection level IP65

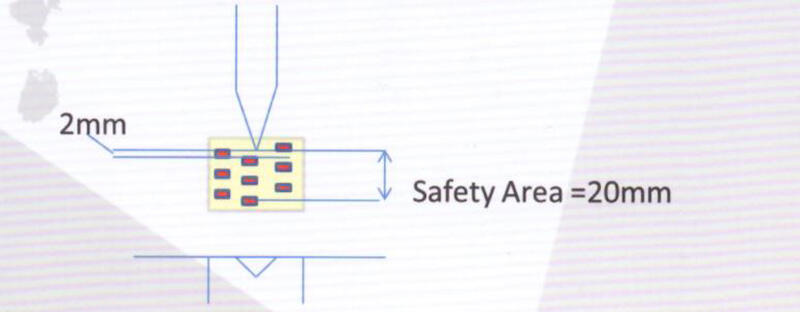

*Speed conversion point can be as small as 5mm

*MSD can be installed on the upper or lower beam of the machine tool

Unique advantages:

*Protection distance up to 15M

*Protect bending below the blade with almost no interference

*Stable performance and same lifespan as the bending machine

*Communicate with the bending machine system to achieve 100% safety and reliability

*The only choice for dual-machine linkage bending machines

*Can be used on any bending machine in the world

2. Bending machine safety upgrade DSP

The DSP laser safety protection device fully protects the safety of the bending machine operators and avoids the danger caused by the rapid operation of the slider on the machine tool.

Once an obstruction (such as a worker's finger) enters the DSP protection area, the DSP will immediately send a signal to interrupt the downward movement of the slider.

Main features:

*CLASS 1M non-hazardous block laser transmitter.

*Safety level reaches CAT 4 and SIL3. Protection level IP65.

*System response time is 5MS. Protection distance can reach up to 15M.

*Speed conversion point: 5mm+stop distance.

*Complies with the EU CE standard for bending machines and the safety standard for Chinese bending machines.

Protection area:

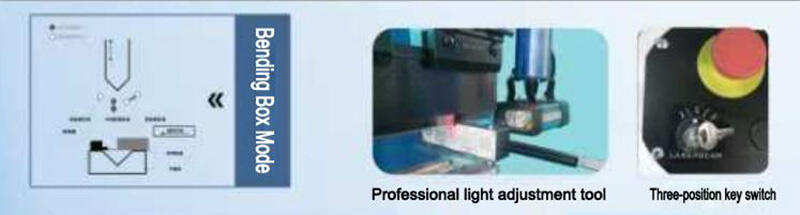

The protection area is divided into three areas: front, middle and back, which protect the operator's operating area, bending area and rear finger area respectively. The three modes can be selected according to the actual working conditions and switched at will according to the needs. Block protection area, convenient for light alignment and weekly testing.

Professional customized bracket

*Aluminum alloy structure, strong stability

*Easy to install, adjustable in multiple directions

*Equipped with linear guide rails, rulers, handles, set different sizes according to different mold heights

*Positionable bracket for easy mold change

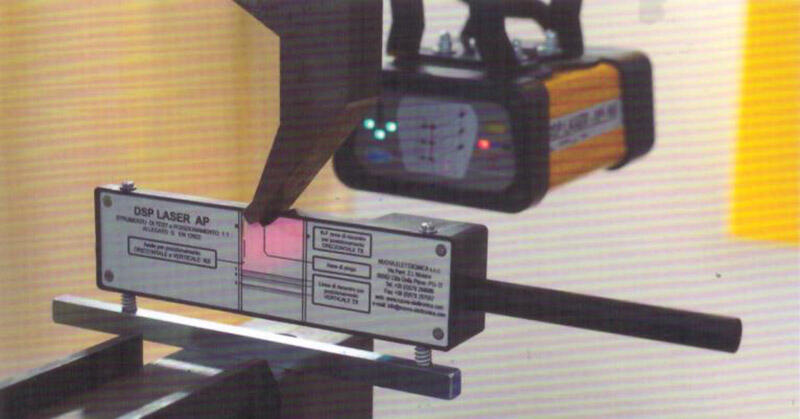

3. DSP AP LASER----For the high-end press brake

Main Technical Features:

*Laser protection, Multi beam Receiver

*Pretective areas, Front, center and rear.

*The safety level is CAT.4 and SlL3

*Detection Case protection degree: lP 65

*Laser classification: class 1 M

*MCS Response time: 2 ms

*DSP LASERAP Response time: 5 ms-Operating temperature 0°C 50°C

*Mounted on the upper beam

*Box Mode Function

*Overrun Distance Test (automatic)

*High Speed Control

*Low Speed Control

*Automuting in Low Speed

*Direction Control

*Change Speed Point: 2mm

*Up to 2 Pedals Control with Antipanic

*Side Repairs Control

*Back Repair Control

*Back Gauge driving

*Automatic tools block

*Emergency Control

*Valve direct driving

*Valve Monitoring

*CNC interface

*Hemming Control

*8 pulsed safety outputs

*8 pulsed safety inputs

*24 safety inputs

*8 safety outputs(maximum current up to 3.2A)

*12 general inputs

*14 general outputs

*3 special function outputs

*2 linear encoders inputs(Y1/Y2)

*1RS232 communication interface

4. DSP EX+MCS EX----For the high-end press brake

Main Technical Features:

*Laser Protection (F+C+R)

*Box Mode Function

*Very Low Muting Point (~2mm)

*Automatic Overrun Distance Test

*High Speed Control

*Low Speed Control

*Automuting in Safety Condition

*Direction Control

*Up to 2 Pedals Control with Antipanic

*Side Repair Control

*Back Repair Control

*Back Gauge Safety Stop

*No Clamping Tools Control

*Emergency Control

*N.4 Valves Direct Driving (up to 3,2A for each output)

*Valve Monitoring

*CNC interface

*No Hemming Control

*RS232 Communication

*Robot Mode

*NO CE Certification

*n.5 Safety Pulse Outputs

*n.5 Safety Pulse Inputs

*n.7 Safety Inputs

*n.4 Safety Outputs

*n.7 Generic Input

*n.6 Generic Outputs

*n.2 Special Function Outputs

*n.5 Inputs for Encoders

*n.1 RS232