Press Brake Tooling

We are JUGAO, world-leading designersand manufacturers of specialistPress Brake Tools.

If you need to:

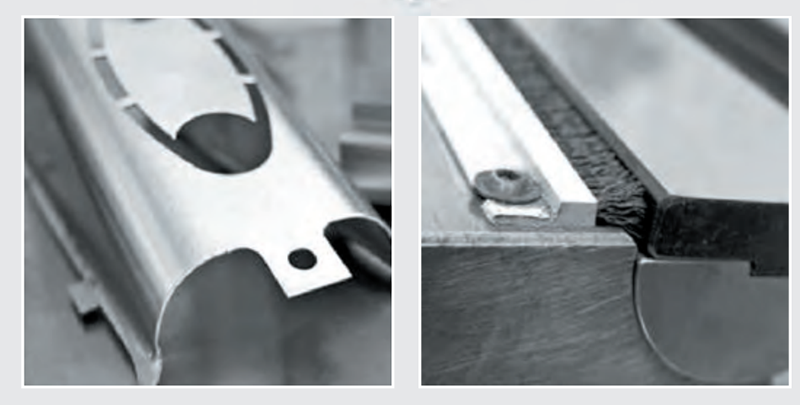

Bend stainless steel, aluminium (or any aestheticmaterials) with little or no marking

Bend small flanges

Bend near to a hole or slot without distortion

Avoid tool contamination

Prevent secondary expensive and unnecessary rework.

Non-Standard lengths areavailable to order on all models

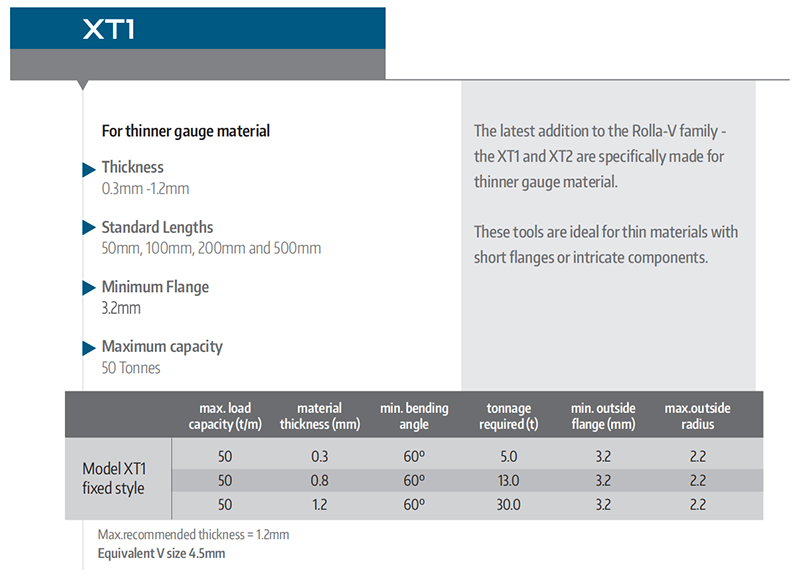

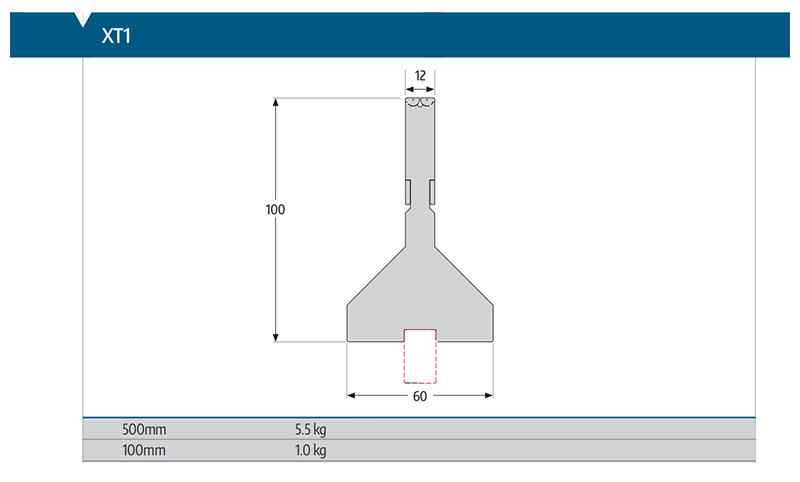

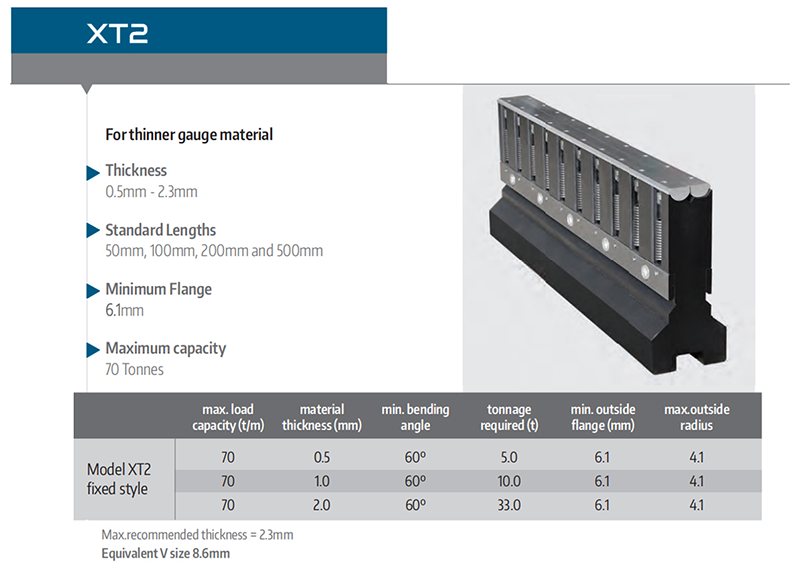

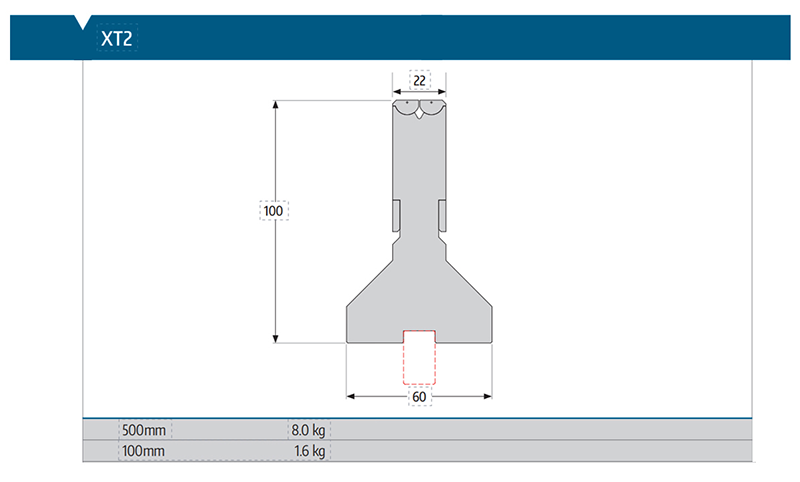

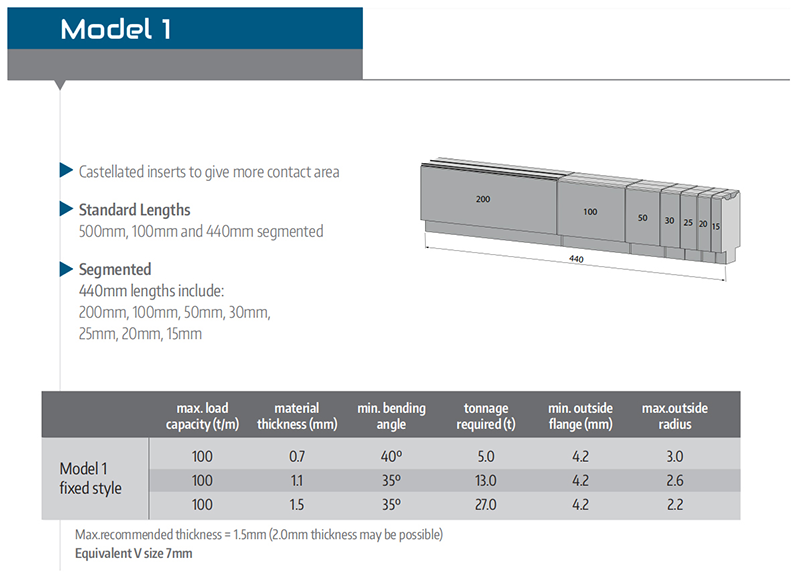

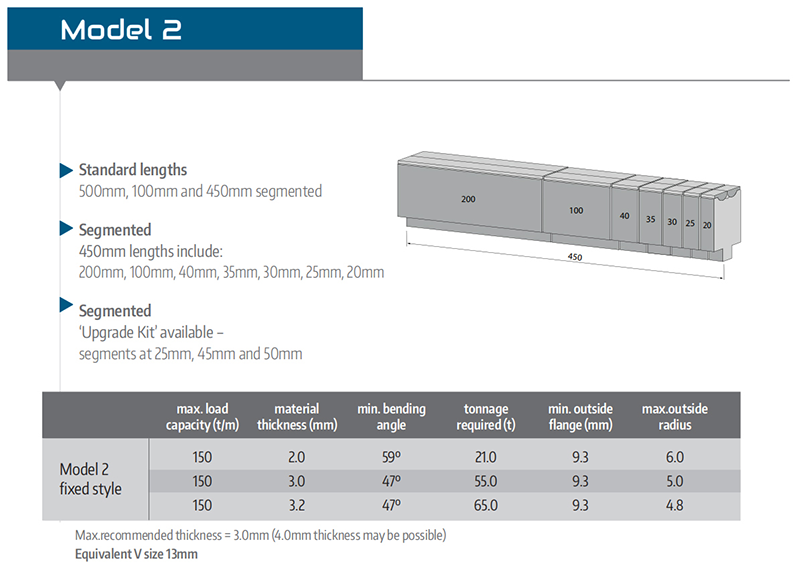

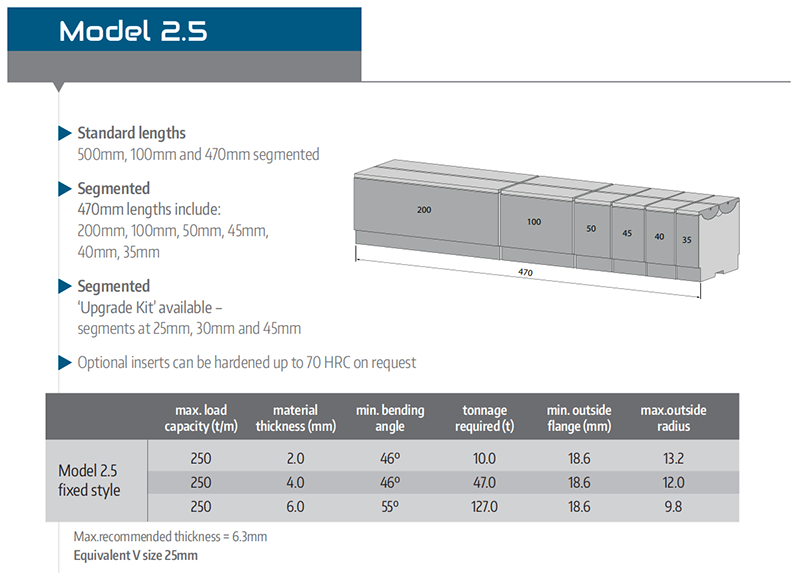

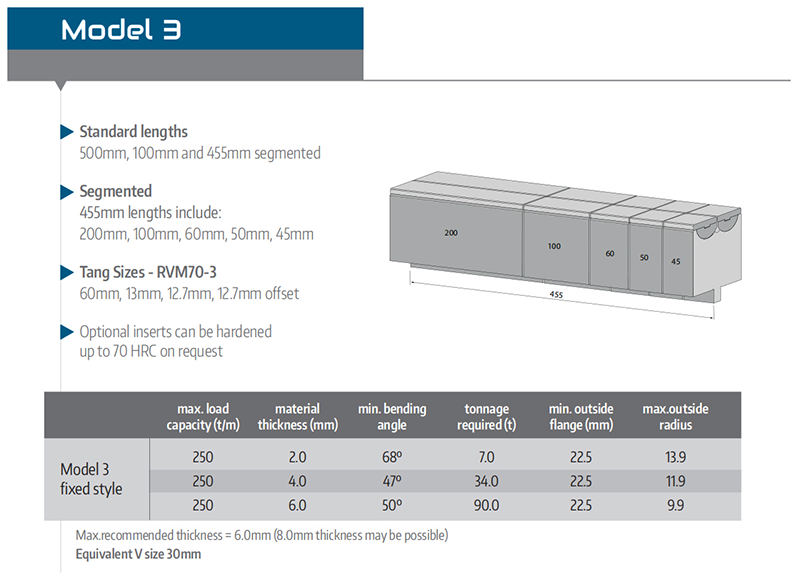

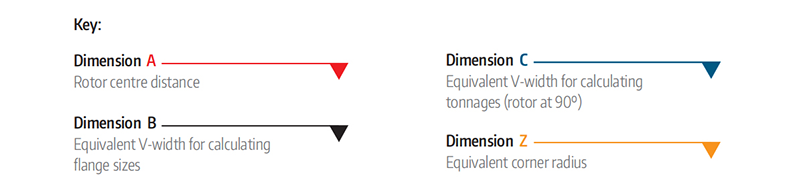

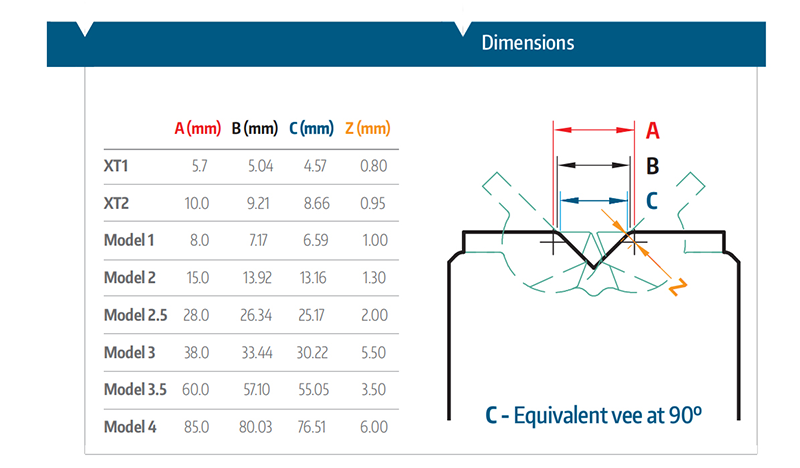

Technical Spec.

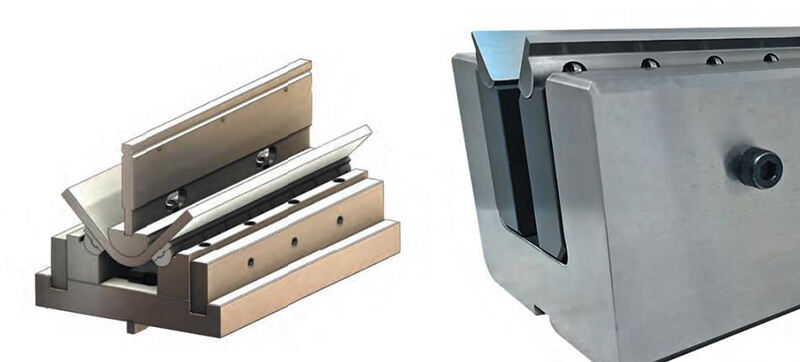

The JUGAO Range of Tools

JUGAO dies are available to suit anymanufacturer's machine.

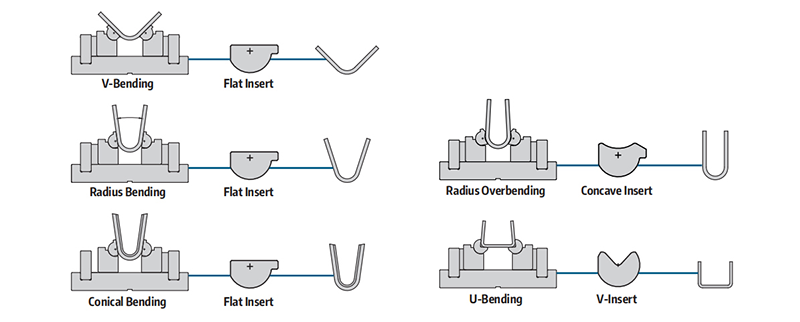

Several fixed sizes are offered as well asadjustable models which are ideal for heavyplate or large radius work.

Appropriate insert materials are used to suitthe typical applications for each size of JUGAO tool, although custom materials may beavailable on request.

Custom sizes and widths are also availablefor specific applications.

Application

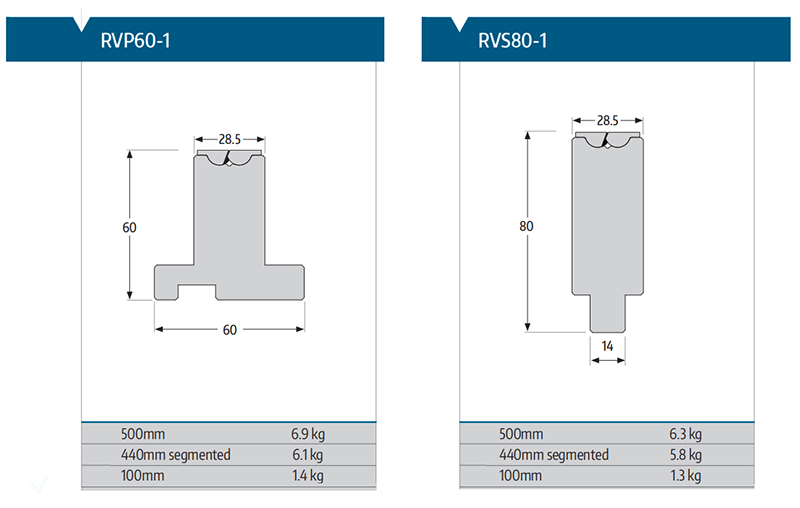

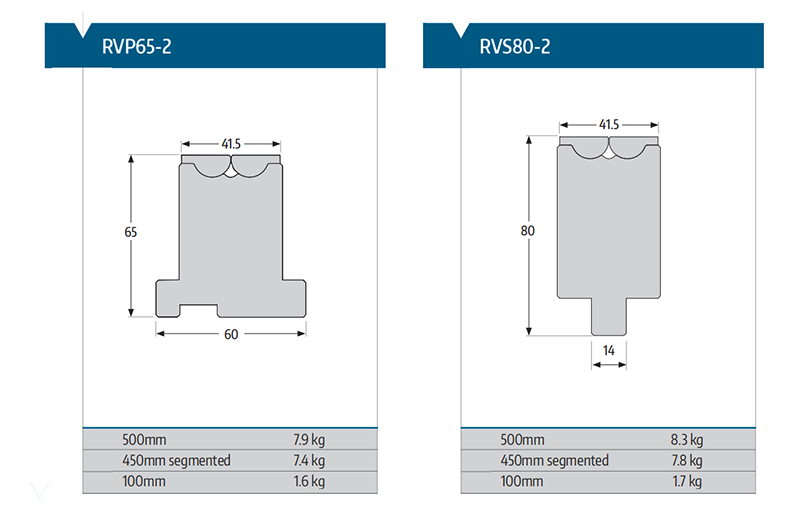

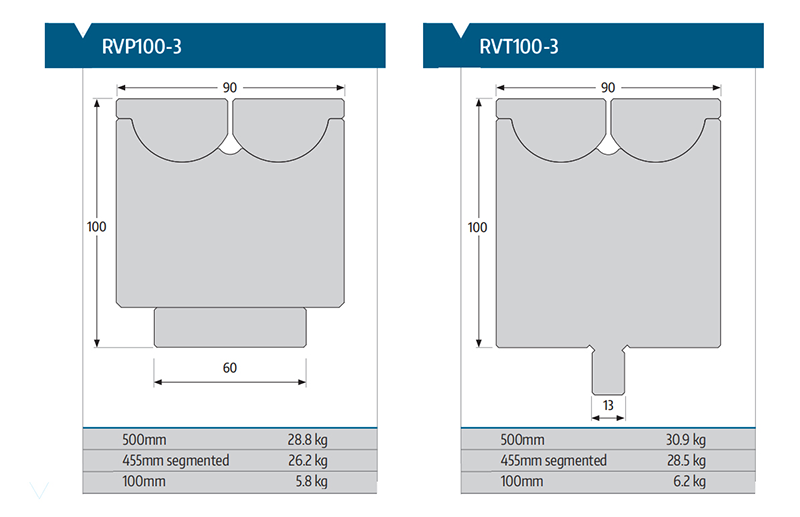

RVP (models 1, 2 and 3)are; 60mm clamping widthsSuitable for Amada, Atlantic, Adira, Bystronic Euro,.Beyeler Euro-B,CR Electronic, Durmazlar, Ermaskan,Gasparini, Guifil, Haco, Promecam.

RVS (models 1, 2) are 14mm tang

Suitable for Amada style single V holder

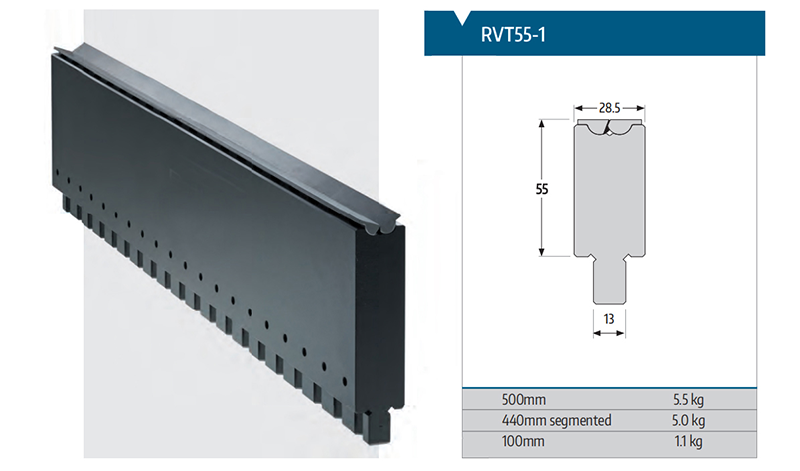

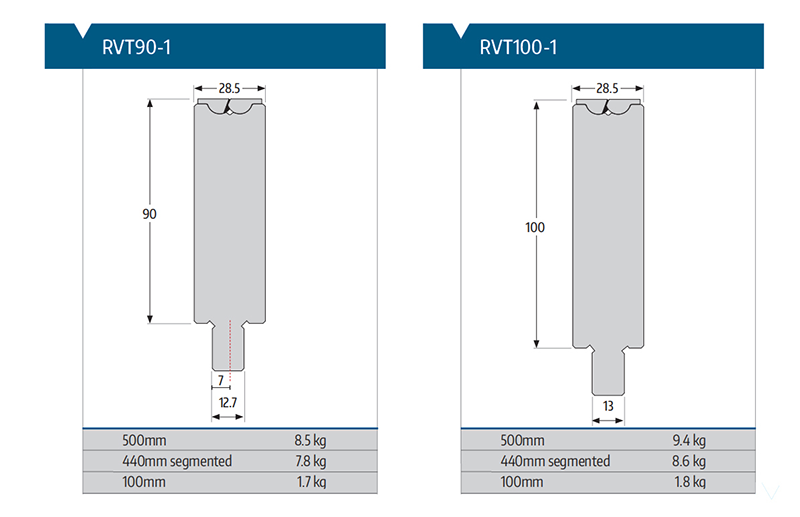

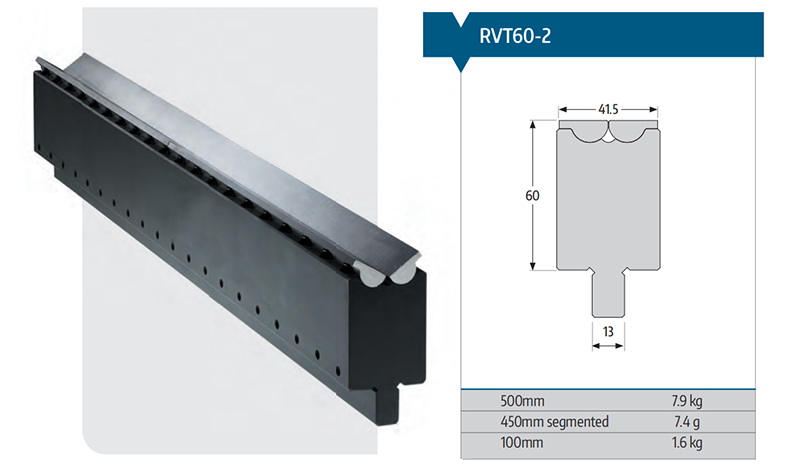

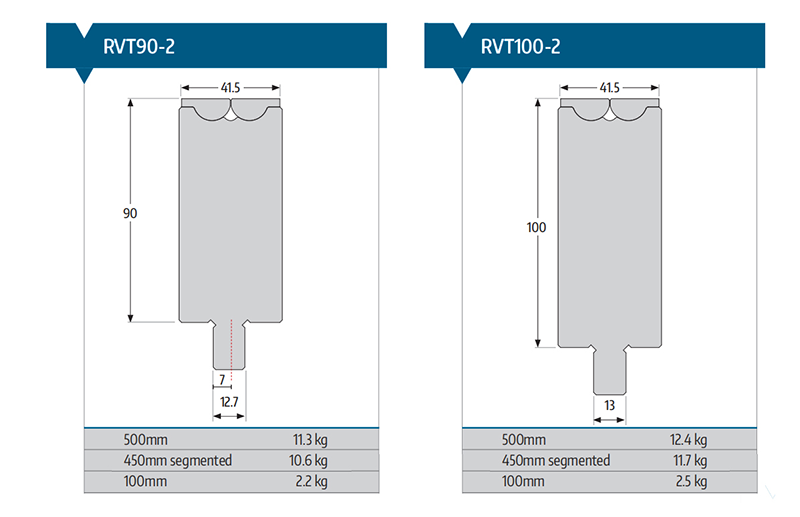

RVT (models 1, 2 and 3) are 12.7mm/13.0mm tangSuitable for Bystronic, Hammerle, Beyeler, EdwardsSafan, SMD, Trumpf.

RVT90 (models 1, 2 and 3)are 12.7mm offset tangSuitable for LVD with offset tang.

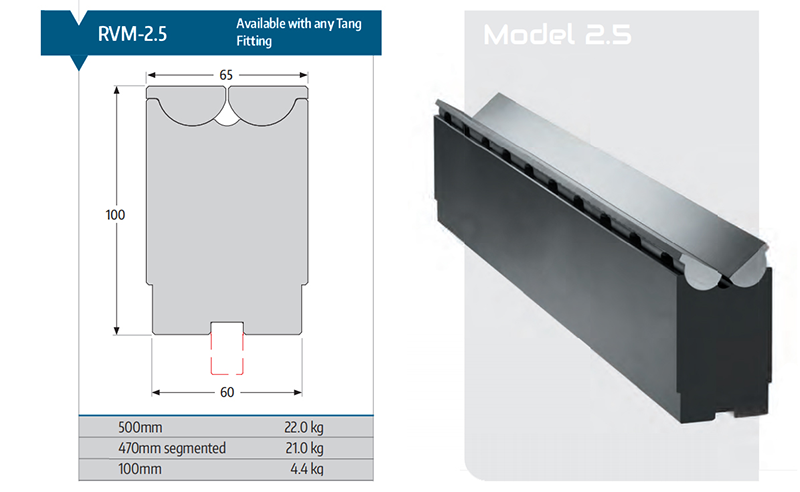

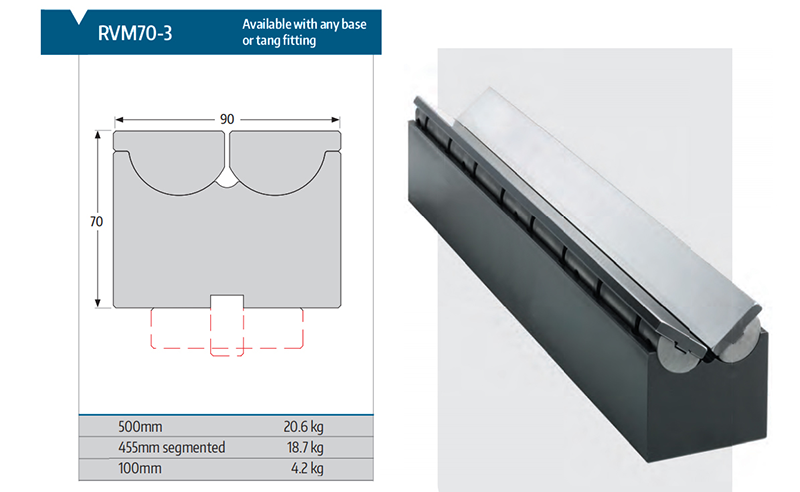

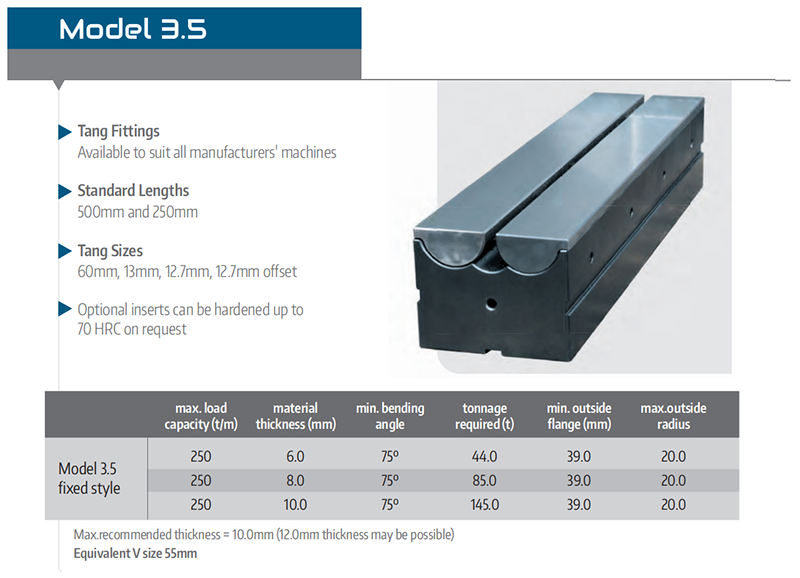

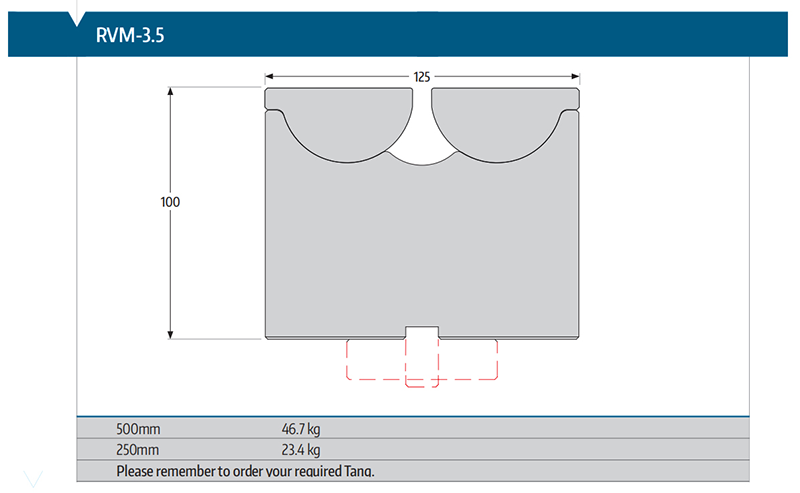

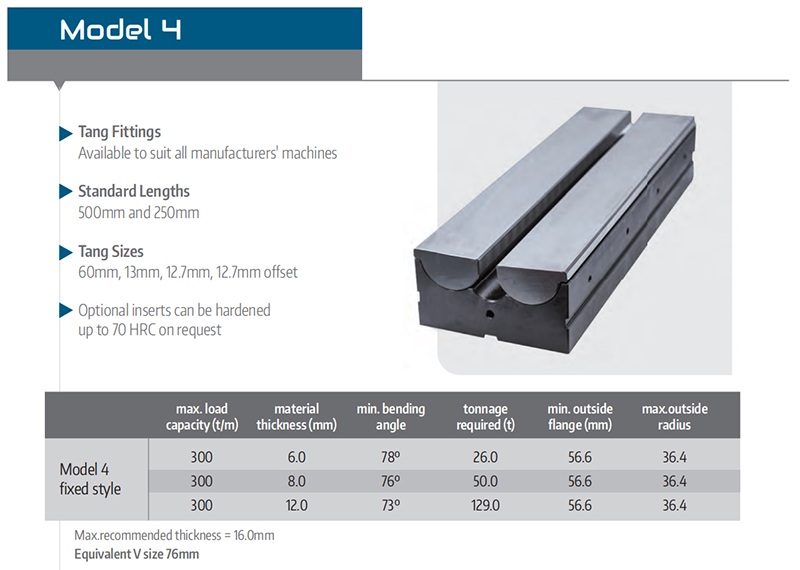

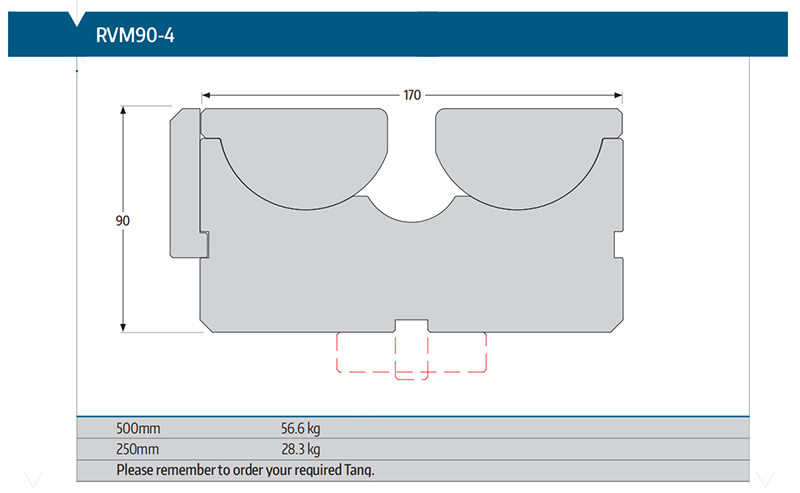

RVM (models 2.5, 3, 3.5 and 4)

Universal clamping with base or tang - all styles areavailable - suitable for any machine brand.

Ifyou cannot see your machine type listedhere we can provide advice and make customfittings to your specification

Materials

Inserts:Through hardened up to HRc60. 70 Rockwell available on request.

Body:42CrMo4 tensile strength 1100-1200M/mm? surface hardened to HRc55

Non-standard insert materials and HRc values are available for specific applications

Advantages

Highly precision ground

Modular

Avoid traditional bending marks

Minimal marking

Extremely short flanges possible

No tool material cross contamination

Bend close to holes and cut-outs

with no deformation

Fewer tool changes

Bends laser cut sheets with no tool damage

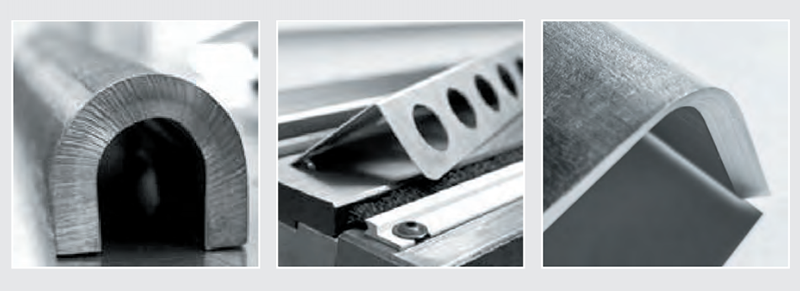

ldeal for radius bending

Exact inside radius

Ideal for tapered or feathered edges

Bends up to 30mm thick material(subject to model selected)

Application and Technical Data

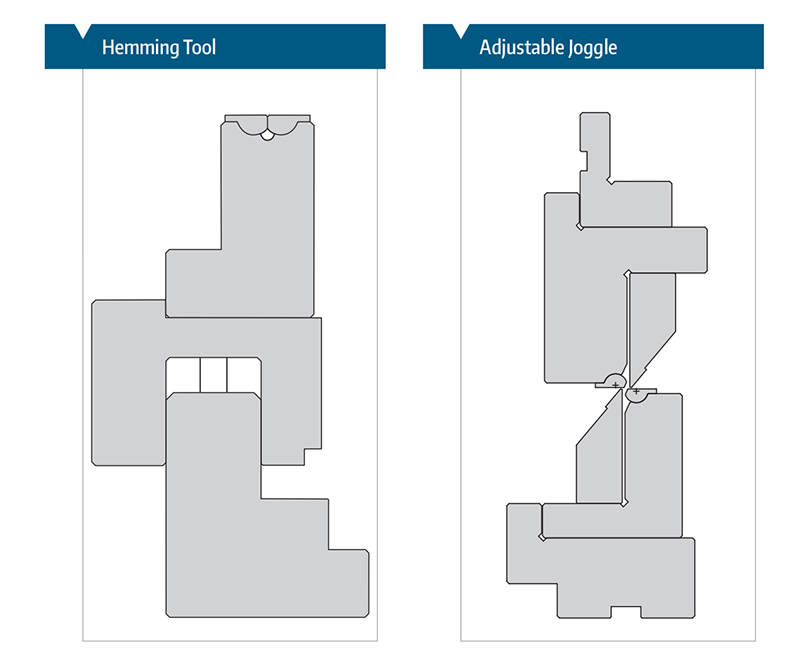

Special Hemming & joggle (z) Tools

# Achieve a small flange and minimise safetyedge marking using the Hemming Too!.

# Minimise joggle Form marking.

# Large range of Z folds available from one tool.

# Contact us ifyou have special applications.

Non-standard lengths available to order

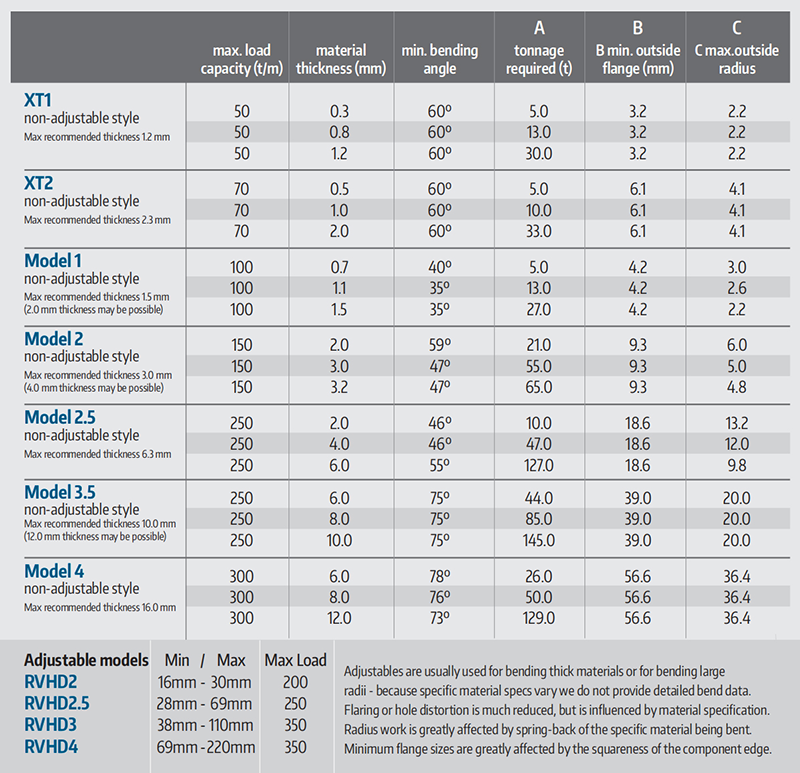

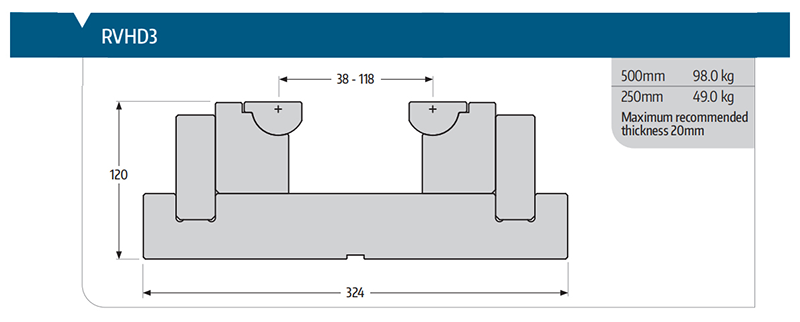

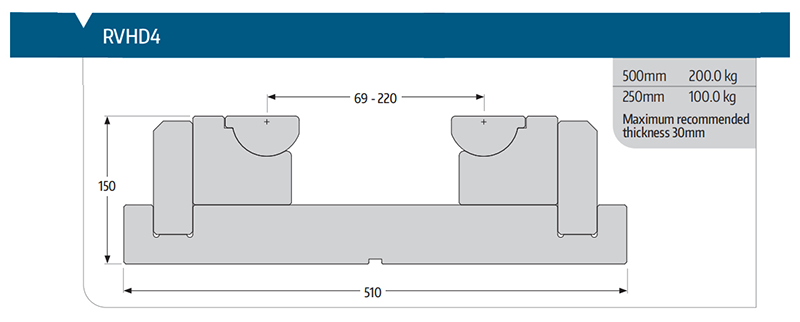

# Several fixed sizes are offered as well as adjustablemodels which are ideal for heavy plate orlargeradius work.

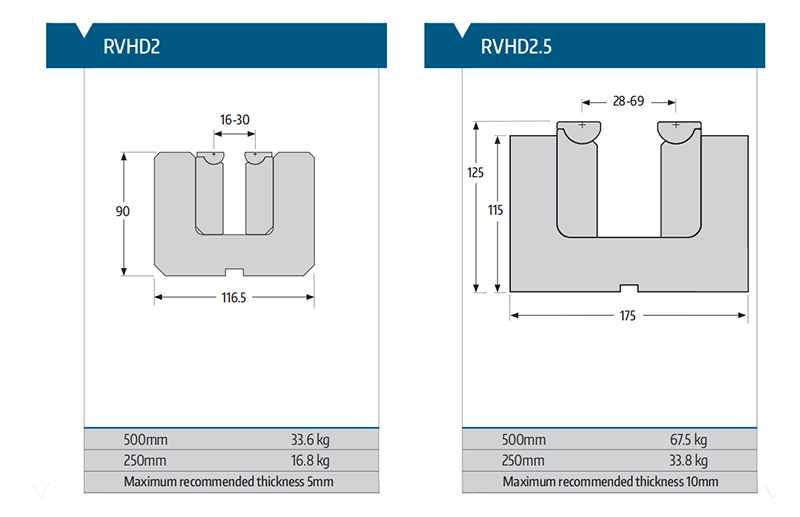

# Standard lengths 500mm and 250mm

# These tools are usually used for bending thickermaterials or making large radius components

# Specific material specifications vary greatly so it isnot feasible to provide detailed data

——eg. minimum flange sizes are greatly affected bysquareness of component edge

——eg. flaring or hole distortion is much reducedwith these tools, but is influenced by specifidmaterial type

——eg. radius work is greatly affected by springbackof specific material and flange sizes

Please call us to discuss specific applications

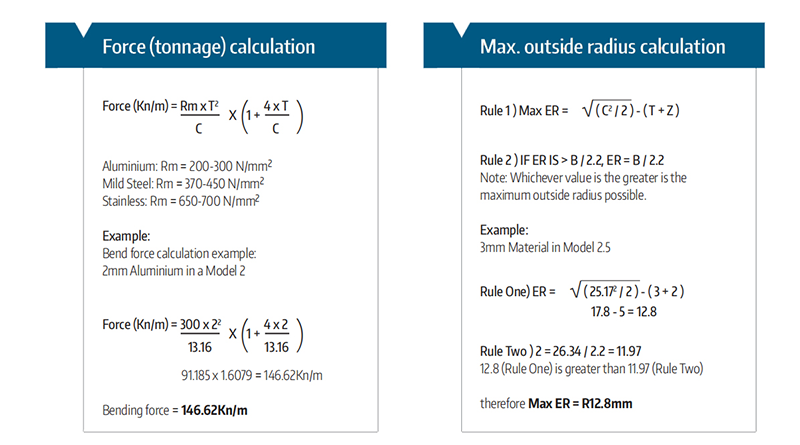

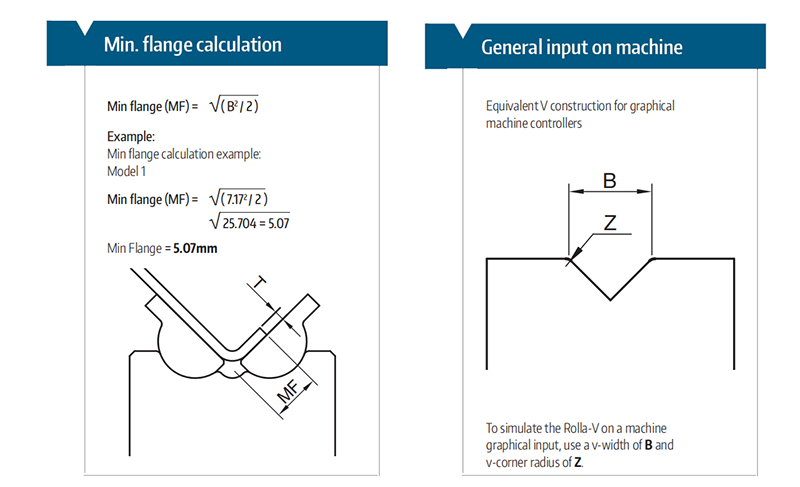

These formulae are for guideline purposes only- they will provide a good indicator of whattonnage, flange size or maximum outsideradius is possible for a specific bend.

Our experience shows thatwhilst these calculationsprovide theoretical values, in practice it is usuallypossible to obtain a more favourable result.

We would recommend that if your requirement isclose to the calculated value, a test bend using yourmaterial and tooling may be advisable to confirmwhat result is actually possible.

This catalogue illustrates ourstandard range of tools.

If you cannot see the product thatyou require we can make bespoketools to order based on your ownindividual specification.

Please call to discuss yourindividual requirements.