How To Choose Press Brake Die

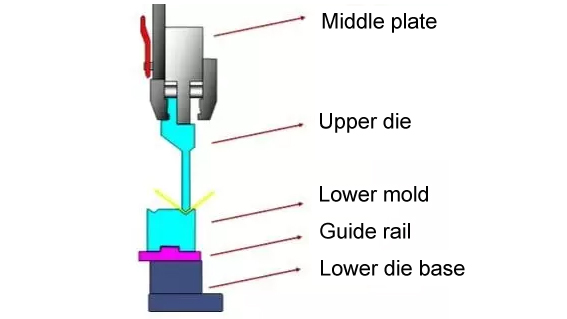

1. Basic structure of bending machine die

General dies are divided into intermediate plates, upper dies, lower dies, guide rails, lower die bases, etc. This type of die is highly versatile and can complete most processing.

2. Selection of bending die

Processing different parts requires the use of different die. First, you must understand the processing parameters of the machine tool and die before you can choose a die that matches each other.

Machine tool parameters include: stroke, processing capacity, opening height, intermediate plate type, etc.;

Die parameters include: upper die handle type (matching the middle plate), pressure tonnage (maximum bending pressure), etc.;

A About the selection of machine tool parameters

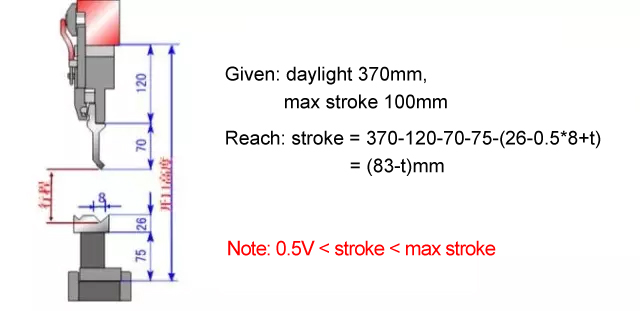

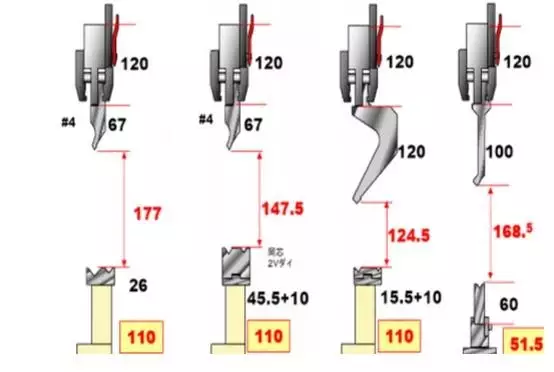

1. Selection of die height

Stroke (mm) = opening height - height of middle plate - height of upper die - height of lower die base - (height of lower die - 0.5V + t) t is the thickness of the sheet (mm)

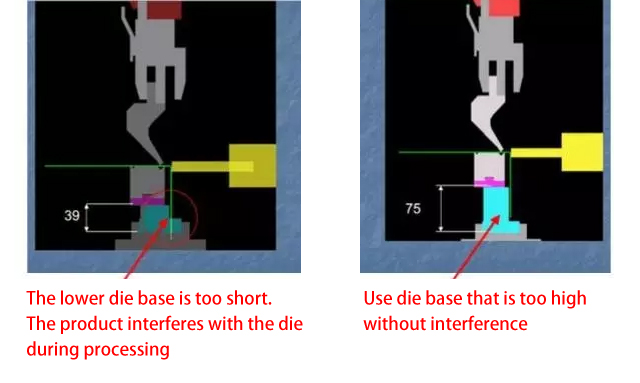

When selecting the lower die base, you should also pay attention to the fact that the lower die base has multiple heights. die bases of different heights are used to match different processes.

Using different die combinations, you can obtain different die combination heights for processing different parts.

B: Regarding the selection of die parameters

1. Upper die handle form

The die handle of the upper die has 3 types to match different middle plates

2. Upper die shape

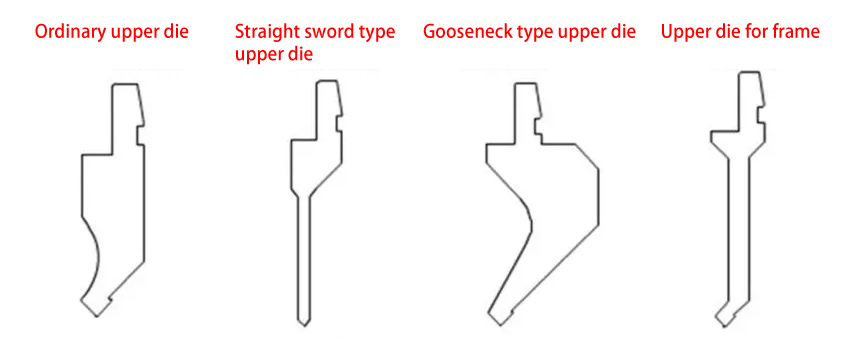

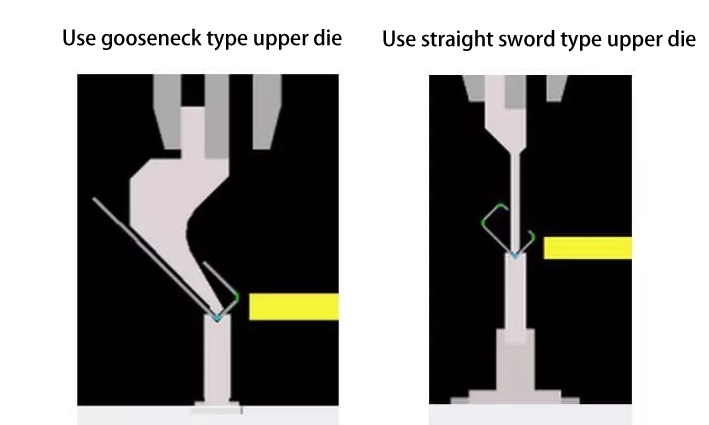

Commonly used standard shapes of upper dies include:

According to different bending needs, choose different switch dies

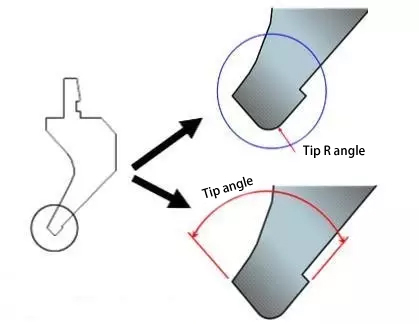

3.Upper die tip R angle and tip angle. The commonly used tip R angles of the upper die are:

(1)0.2R (2)0.6R (3)0.8R (4)1.5R (5)3.0R

Choose a suitable tip R: Generally, R0.6 is used when the tip is less than 3mm.

The tip angles of standard upper dies are: 90 degrees, 88 degrees, 86 degrees, 60 degrees, 45 degrees, 30 degrees; etc.

The included angle of the die should be smaller than the processing angle. For example, if we bend the workpiece to 90 degrees, we use an 88 degrees included angle die.

4. Lower die form

Generally, the lower die is divided into single V and double V. Among these two types, there are segmented and whole segments. Different die types are suitable for different processing needs.

Generally speaking, single-V dies are more versatile than double-V dies, and split dies are more versatile than whole-section dies. Our company generally uses double V and triple V lower dies.

5. Lower die V width and V groove angle

The relationship between the selection of lower die V-groove and material

thickness (T):

| T | 0.5~2.6 | 3~8 | 9~10 | 12 above |

| V | 6XT | 8XT | 10XT | 12XT |

The V-groove angle of the lower die is the same as that of the upper die.