Commonly used operating systems for JUGAO bending machines

During the development of the bending machine, the initial machine tool positioned the primary electromechanical stop. As the technology advances, it is gradually replaced by the digital display operating system, and the Eston E10 system has the highest evaluation for the digital display system.

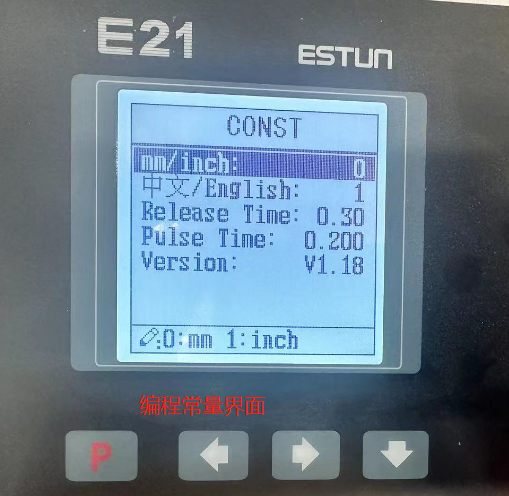

At this stage, it has been replaced by Eston's E21 and E21S. At the same time, other domestic systems are also gradually launched, representing NC89, etc., but E21 and E21S maintain a market share of more than 50%. In addition, with the emergence of torsion-axis CNC systems, torsion-axis CNC models have also been recognized by the market. However, due to the high prices of systems such as DELEM's DA41 and ESTUN's E300, the market utilization rate is low. However, with the introduction of other domestic CNC systems in recent years, the price of system options has dropped to freezing point. Torsion axis CNC models are also recognized by most users. At the same time, JUGAO has also launched the JUGAO-T8 bending machine operating system in conjunction with electronic control developers.