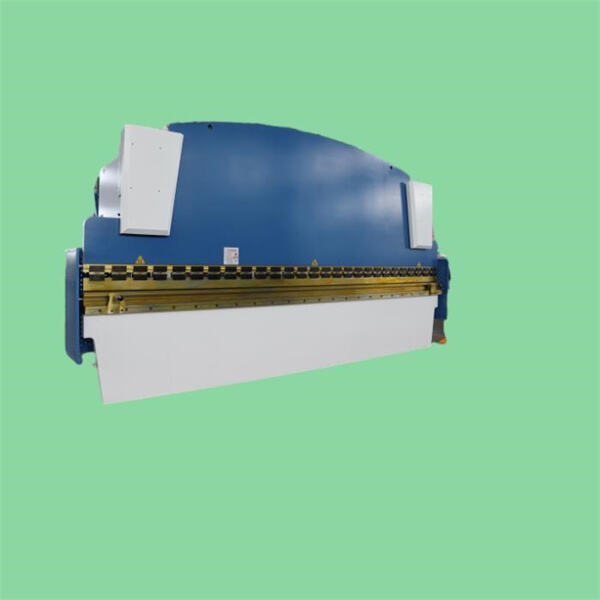

Electric sheet metal brake It is a unique kind of machine created for easy bending of metals. This is especially useful to people who work with metal in any form like the manufacturers of race cars, and airplanes. This brief article takes you on a journey. A glimpse of how an electric sheet metal brake can redefine your experience with working the magic into those precious metals!

Specifically, to shape metal of a variety of forms - that is where an electric sheet metal brake really comes in handy. It is very quick and precise; manual brakes for such a task usually sacrifice time and exertion on the operator's part. User Experience Another important aspect of the machine that receives high-feedback is how user-friendly it performs so well in giving machinists and operators time to learn more on creativities at work, which include drawing-out and finalising projects.

There are many benefits to using an electric sheet metal brake. One of the major advantages is in using time and resources during metal bending. An electric brake - unlike manual machines that need enough muscle power to work with the metal - simply, you press a button and it will do your job. Furthermore, while electric brakes are more accurate than manual ones and make it possible to manufacture parts that fit precisely with one another (a dissuasion of the occurrence of errors and waste materials).

Efficiency is key when it comes to large-scale projects such as building a car or an airplane. And that's why the electric sheet metal brake is there to save us! Increasing Productivity = Fewer Delays In Projects, Sticking To Timelines And Happy Clients/Customer And because the machine is capable of producing more parts in less time than manual brakes, that means you can do lot more work and earn a percentage greater roi.

Additionally, an electric sheet metal brake is capable of providing a significant boost to ones stopworking capabilities. It allows people to create shapes with metal that would be difficult or impossible to do by hand, for example bending around curved edges. And because of this broader possibility, more intricate patterns and forms can be designed. In addition, the system allows work with thicker metal sheets that allow to use a more diverse array of materials in design solutions.

In short, the electric sheet metal brake proves to be a game-changing device that changes how industry do metalworking. Considering how it can save time, boost productivity and improve one's overall metalworking abilities (especially if you work with metals regularly), thus the option is worth every single penny. From birdhouses small to skyscrapers tall, an electric sheet metal brake allows you perfect end products. Hence, regardless of whether you are a professional metalworker or new to the craft, this tool can help make your job easier allowing quicker processes and finer products. By choosing an electric sheet metal brake, you can save time and materials in your production processes while producing high quality workpieces.

Press electric sheet metal brake renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain electric sheet metal brake advantages.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities electric sheet metal brake production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales electric sheet metal brake well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.