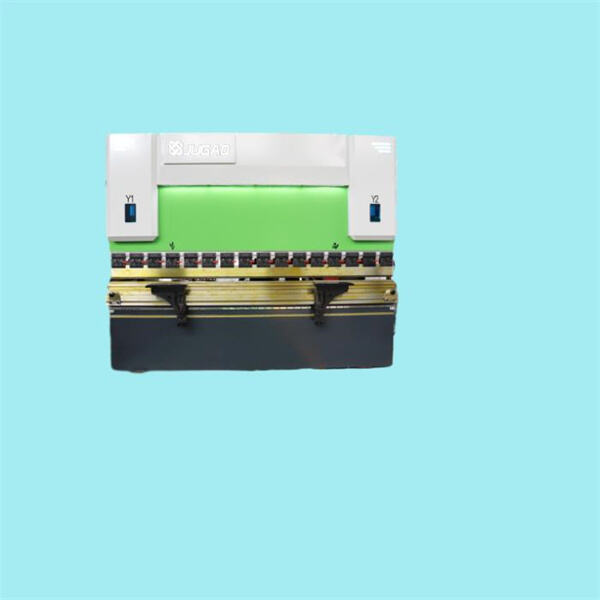

Metal can manipulated in to other shapes utilizing a CNC press brake machine. A computer program drives this machine to create accurate metal bends. It is capable of bending different material sheets like metals with precise measurements.

The punching machines are used for the small as well medium range of production i. e., up to many hundred thousands pieces and CNC press brakes help in making things out of sheet metal like cutting, bending, welding & assembling. It allows developers to fabricate more intricate designs quicker and producing less waste. These machines are also very precise and allow one to run only a small quantity of product.

Wanted faster and more efficient CNC press brakes are used for a newer_least. Their built-in tools that can both, automatically change and reflect accurate angles. These are still electric machines, but motors vibrate less and use energy more efficiently than older vibrations (and make fewer noise).

CNC press brakes work with computer design programs to assist in easier bending. Also, they come with proper safety features to allow the people using them in case of any malfunction. They can also be linked to other equipment, such as for transport of material.

In conclusion, the CNC press brakes can be fascinating as they fabricate things out of metal fast and efficiently. Always improving and utilizing new technology to make the production of metal that much easier.

Have you ever been fascinated by the metal objects with complex shapes? A CNC press brake is one such interesting invention that enables the aforementioned. CNC(C omputer N umerical C ontrol) is a technology to use computers and software using information (such as metal sheet bending process of steel size with precision.

The CNC press brake has an important panel in sheet metal fabrication that is carried out by bending, cutting, welding and assembling metallic sheets to create different kinds of products. CNC press brakes make it possible for fabricators to create complex shapes more quickly, and with less material waste.

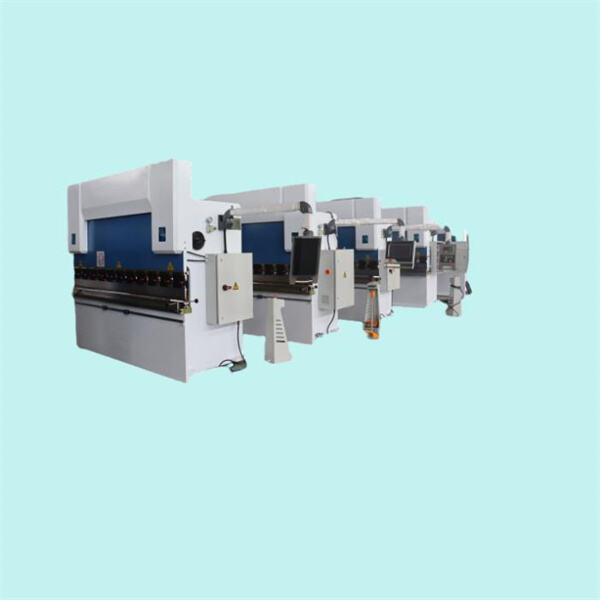

Press Brakes known reliability precision cnc press brake various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent cnc press brake capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective cnc press brake production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

recognize significance RD cnc press brake. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.