How a Bending Machine Plate Can Make Your Life Easier

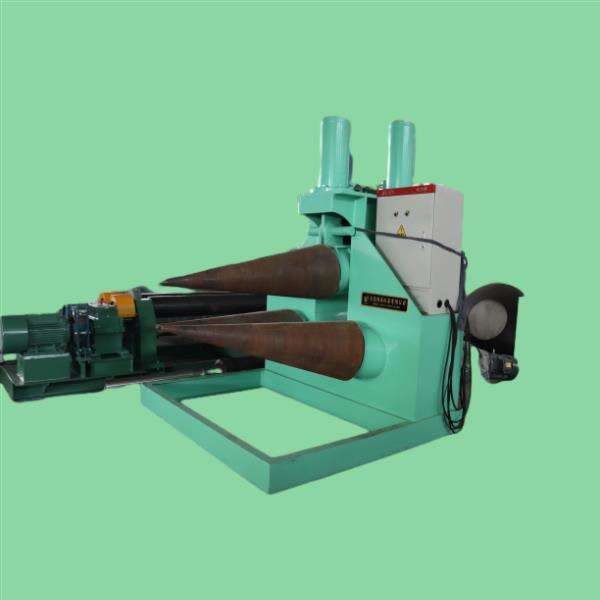

Have you ever wondered how metal objects are shaped into different forms and sizes? Chances are that they were formed using a bending machine plate. This piece of equipment is essential tool for industries such as manufacturing and construction, as it allows for efficient and precise metal bending. We will explore advantages of using JUGAO plate bending machine, its innovation, how to use it safely and effectively, and quality of the service and application it provides.

Using a bending machine plate offers many advantages over traditional metal bending methods. Firstly, it allows for faster production time, as it can create multiple bends in short amount of time. This results in increased productivity and reduced labor costs. Secondly, JUGAO Bending Machine Plate produces more precise and uniform bends, can enhance quality of finished product. Thirdly, bending plate machine minimizes material waste as it can bend metal with reduced scrap costs.

Bending machine plates continually being upgraded and innovated to cater to changing industry demands. They have become more versatile, compact, and user-friendly. With addition of computer software, operators can now program desired angles and dimensions, allowing for greater accuracy and precision. This innovation has made JUGAO bending machine plate critical machine in large industries.

Safety is top priority when operating a bending machine plate. Operators need to go through proper training and certification before using machine, as it can be dangerous if used incorrectly. Manufacturers have incorporated safety features into machine, such as interlocks and guards, to reduce risk of accidents. Additionally, JUGAO bending roll machine essential to follow safety protocols, such as wearing protective equipment, to avoid any injury or damage to machine.

Using bending machine plate requires a few straightforward steps. Firstly, metal sheet is inserted into JUGAO machine, aligned with the desired angle and dimension. Secondly, operator sets the bending angle, clamps the sheet, and lowers the bending blade. Lastly, blade is raised to release the metal sheet, and the finished product is removed. Although it requires practice, using steel plate bending machine can produce high-quality and precise results.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market bending machine plate using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

Press Brakes known reliability precision bending machine plate various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

bending machine plate accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader bending machine plate.