Bendy machinesgiving you a sense of awe nature? Such tools have the extraordinary capability to reshape flat metal sheets into a multitude of shapes and angles. So let us discuss how bending machines are transforming metal fabrication and becoming the staple of modern manufacturing.

Metalworking used to be a long and laborious endeavor. Hour after hour, skilled workers would bend metal by hand to fit specific profiles and angles. But with the advent of bending machines,suddenly everything changed!

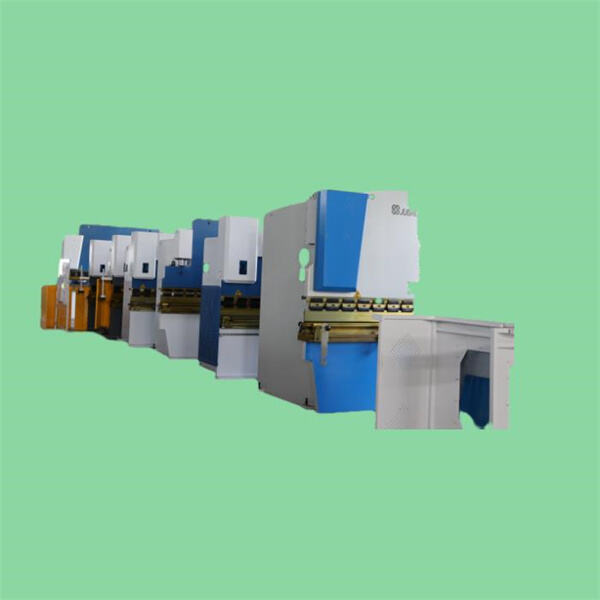

Hydraulic bending machines are capable of using hydraulic power to bend metal with more speed and accuracy. Their craftsmanship is amazing because they can bend metal in any curve or angleposible, from the sweetest curvature to complicated geometry.

The amazing flexibility of folding machines to let us flying in the unlimited sky! So these amazing tools can be use in various application. They are adept at shaping metal pipes, tubes and beams into the most precise shapes. Additionally, they specialize in forming sheet metal for individual parts in machinery as well as cars and other equipment.

Bending machine benefitsAmong the key advantages of using a bending machinery is that this can supply an unbeatable amount of preciseness. These machines bend metal with impeccable precision, ensuring each piece fits perfectly into the project for which they are intended. In addition to improving the quality of a finished product, this precision also reduces waste-that is cost savings!

Next, we turn our attention to the state-of-the-art technology behind precision bending. Newer developments have taken these bending machines to higher levels of power and efficiency. The bending process has been automated over the years, with computer-controlled systems directing state-of-the-art bending machines.

When using computerized bending machines, an operator is able to set accurate measurements and angles into the machine which can then execute perfect bends on its own. So, not only this automation helps in increasing the productivity but also improves the quality of manufacturing products by reducing human errors.

bending machine brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

Quality bending machine Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

bending machine importance RD support after-sales. press brakes, laser cutting machines, rolling machines pipe bending equipment items, offer extensive range after-sales support includes Spanish after-sales service, ensure customers able use product without worry. continuing invest product development upgrade technology innovation. allows us meet evolving customer requirements keep leadership position market.

bending machine Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.