- Overview

- Inquiry

- Related Products

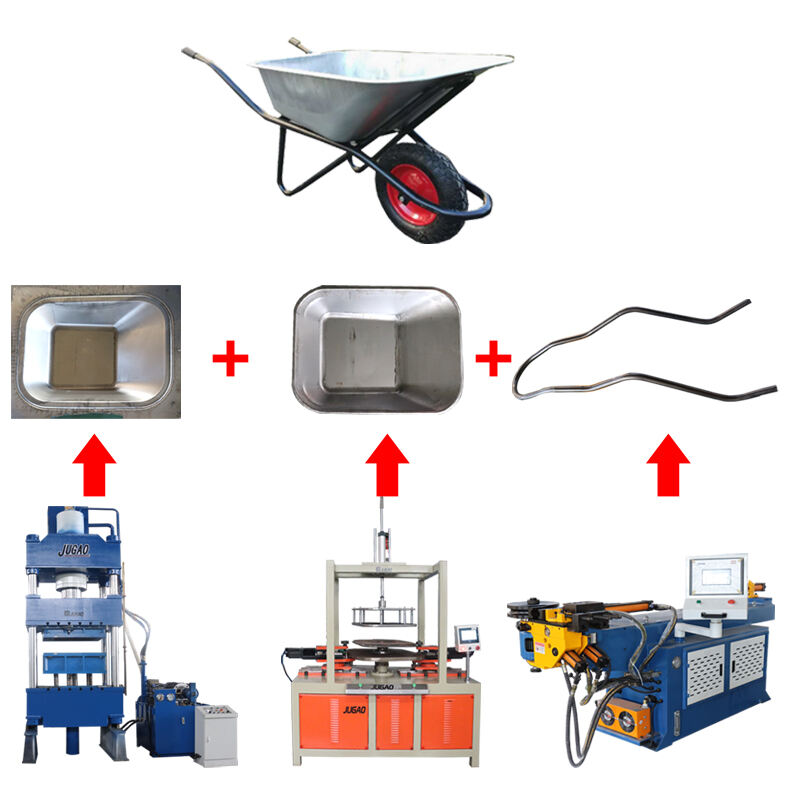

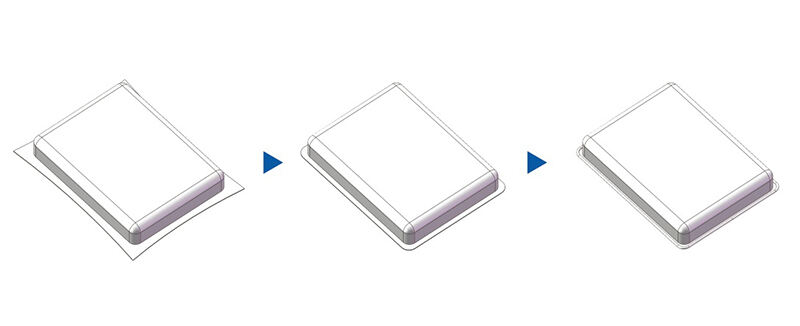

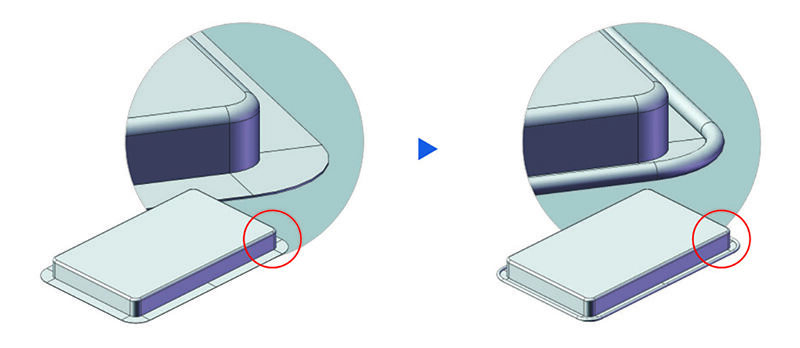

Wheelbarrow is a special transport vehicle for transporting construction waste, soil, stone, etc., and is usually used in urban construction and road construction. The production process of wheelbarrow bucket includes: stretching, blanking, forming, curling, etc. The bucket body can be formed by stamping and stretching. The main processing equipment of this process is stretching forming hydraulic press, curling machine, and pipe bending machine. The first is the forming part, which is related to the initial shape of the wheelbarrow. Using a raw steel plate with a thickness of 1.0mm, with the help of the synergy of the hydraulic press and the forming die, the raw steel plate is stretched to obtain the approximate shape of the wheelbarrow. The second is the trimming step. The wheelbarrow has a large width around it after forming, and the excess part needs to be accurately cut off. The next step is the hemming step. The hemming machine is used to flanging the wheelbarrow around to make its edges round. In this way, the wheelbarrow can be placed more firmly on the frame. The last step is the production of the frame. The hydraulic pipe bending machine can efficiently complete the production of the frame. If you choose a fully automatic pipe bending machine, the production process will be easier and more convenient.

1. The forming part of the wheelbarrow——Hydraulic forming press

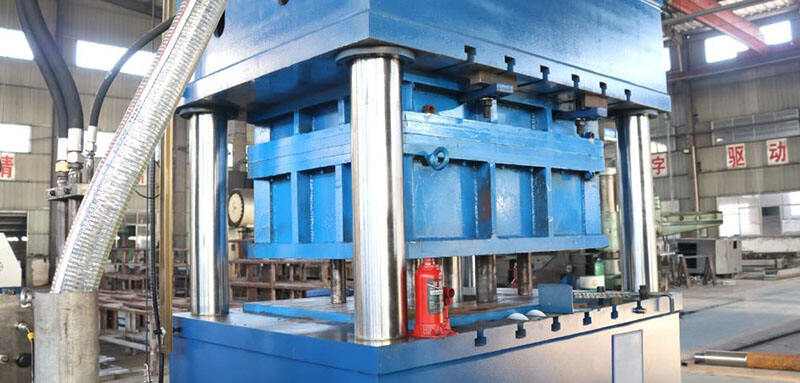

The wheelbarrow special production equipment forming hydraulic press adopts a four-column structure, the hydraulic system adopts a cartridge valve, the electrical system adopts PLC automatic control, and has inching and semi-automatic functions. The stroke, pressure and speed of each operating component are self-adjustable within a certain range to meet the needs of metal product forming parts. It is equipped with a special mold for stretching wheelbarrow, and the stretching forming is carried out in one time, which greatly improves the quantity and quality of production.

The stretching wheelbarrow hydraulic press (with stretching die) is a common hydraulic equipment. Its structure mainly includes the following components:

1) Upper beam: The upper beam is the upper supporting structure of the tensile four-column hydraulic press, usually welded from high-strength steel plates. A hydraulic cylinder is installed above the upper beam, and the hydraulic pressure provided by the hydraulic system drives it to move up and down.

2) Lower base: The lower base is the bottom support structure of the four-column hydraulic press, usually welded from steel plates, with sufficient rigidity and stability. The lower base is equipped with bolt holes fixed to the ground to stabilize the hydraulic press.

3) Hydraulic cylinder and piston: The hydraulic cylinder is one of the core components of the hydraulic wheelbarrow press (with a stretching die), usually installed between the upper beam and the lower base. The hydraulic cylinder includes a cylinder barrel and a piston. The hydraulic pressure is generated by the piston and drives the movement of the upper beam.

4) Hydraulic system: The hydraulic system is the power source of the four-column hydraulic press, including hydraulic pumps, hydraulic valves, oil pipelines and control systems, etc. The hydraulic system is responsible for providing hydraulic pressure, controlling the movement of the hydraulic cylinder and regulating the pressure.

5) Work surface: The work surface is a platform on the stretching wheelbarrow hydraulic press (with stretching die) for placing workpieces. The work surface can be fixed or movable to accommodate workpieces of different shapes and sizes, and the stretching force is applied through the movement of the hydraulic press.

6) Safety protection device: In order to ensure the safety of the operator, the stretching four-column hydraulic press is usually equipped with various safety protection devices, such as emergency stop buttons, protective covers, safety sensors, etc., to avoid accidents.

The main features of the wheelbarrow stretching die are that the upper die adopts a convex die that is similar to the inner cavity of the wheelbarrow, and the edge and lower die adopt edge and concave dies that are similar to the outer edge of the upper opening of the wheelbarrow. It has the advantages of fast forming, no welds, no seams, no water leakage, and strong and durable.

The wheelbarrow wheelbarrow stretching die consists of the following main parts:

1) Upper die: The upper die is the part of the die corresponding to the lower die. It is usually located above the wheelbarrow and is used to apply pressure and stretching force. The shape and size of the upper die are consistent with the desired wheelbarrow bucket shape.

2) Lower die: The lower die is the part of the die corresponding to the upper die. It is usually located below the wheelbarrow bucket, provides support for the wheelbarrow bucket, and realizes the stretching operation by moving up and down. The shape and size of the lower die are consistent with the desired wheelbarrow bucket shape.

3) Stretching mechanism: The stretching die is usually equipped with a specific stretching mechanism to control the movement between the upper die and the lower die, and apply stretching force to change the shape of the wheelbarrow bucket. The stretching mechanism can be implemented using hydraulic, pneumatic or mechanical means.

4) Auxiliary components: In addition to the upper die, lower die and stretching mechanism, the wheelbarrow bucket stretching die may also be equipped with other auxiliary components, such as fixing fixtures, guide components, control systems, etc., to improve the stability of the die and the accuracy of operation.

Performance advantages of special production equipment wheelbarrow forming hydraulic press:

(1) It adopts a four-column guide structure with high guide precision and strong resistance to lateral force.

(2) Simple structure, economical and practical. Made of 45# integral cast steel, it has good rigidity, solidity, durability and high precision.

(3) The main cylinder of the wheelbarrow forming hydraulic press is made of alloy cast steel and precision ground, which ensures high reliability under high pressure.

(4) A CNC system can be added. During the stretching process, the master cylinder and blank holder force change within the rated range along with the sheet area (optional).

(5) The hydraulic press has the functions of fast work advance and slow mold profiling, which improves production efficiency and mold service life.

(6) It can be adjusted according to process requirements within the specified range: two molding processes of constant pressure and fixed stroke, easy to operate.

Wheelbarrow special production equipment forming hydraulic press maintenance:

1) It is recommended to use 32# and 46# anti-wear hydraulic oil for working oil, and the oil temperature should be within the range of 15~60 degrees Celsius.

2) The oil is allowed to be added to the oil tank only after strict filtration.

3) The working oil is replaced once a year, and the first replacement time should not exceed three months.

4) The slider should be frequently filled with lubricating oil, the exposed surface of the column should be kept clean at all times, and the engine oil should be sprayed before each work.

5) The pressure gauge should be calibrated and checked every six months.

2. Wheelbarrow flanging process——Profiling shearing and curling machine

Product features

1) Suitable for trimming and curling large-sized round products

2) Extended workstation, suitable for a wide range of products

3) Suitable for a variety of materials such as aluminum, iron, copper, etc., with strong applicability

Product parameters:

Input voltage: 380V

Total power: 4.5kW

Transmission mode: gas-liquid mixture

Suitable thickness of workpiece: 0.4-1.0mm

Suitable height of workpiece: 30-300mm

Diameter range of workpiece: 200-700mm

Equipment function: profiling, trimming, curling

3. Frame production——Hydraulic pipe bending machine

Features of hydraulic pipe bending machine

1) Automatic identification of machine tool/workpiece dynamic characteristics → fast and good processing

2) High-speed single-head hydraulic pipe bending machine, using microcomputer control, multiple sets of programs, multi-angle settings, making operation simple and convenient.

3) Chinese and English subtitles display, human-computer dialogue operation, manual, half-cycle, full-cycle operation mode can be selected at will.

4) High-performance imported hydraulic valves and electrical components are used.

5) Equipped with a large-capacity cooling system to effectively control the working temperature.

6) The whole machine has the characteristics of easy operation, stable performance, high work efficiency, and high safety factor. It is an ideal equipment for the pipe processing industry.

7)Manual and semi-automatic operation modes can be selected at will, and the mobile foot switch has both start and emergency stop functions.

Every link of this advanced production line is carefully designed to create high-quality wheelbarrows.