- Overview

- Inquiry

- Related Products

CONTROLLER

Customize The Controller For Your Press Brake

The E22 bending machine CNC system has a high cost performance, and has rich software functions, simple and smooth hardware design, simple and easy operation, and can realize multi-step programming, automatic positioning, automatic step change and other functions. Various control functions optimize the electrical design of the machine tool, improve the operability and electrical reliability of the machine tool, and have built-in hardware self-diagnosis functions, thereby improving the maintainability of the equipment.

Press Brake Machine Frame Structure

1.Machine frame is of steel welding structure through finite element analysis and optimal design, featuring hi-rigidity and strength.

2.Welding stress is deleted after the annealing treatment for welding parts in the electric furnace, which can avoid the frame deformation in future. Sandblasting remove the rust on the welding parts and the anti-rust painting apply to the welding structure parts.

3.Heat Treatment Processes:JUGAO press brake and laser cutting machine steel frames undergo annealing at over 600⁰ to relieve stress and they are built to last years of heavy use without distortion.

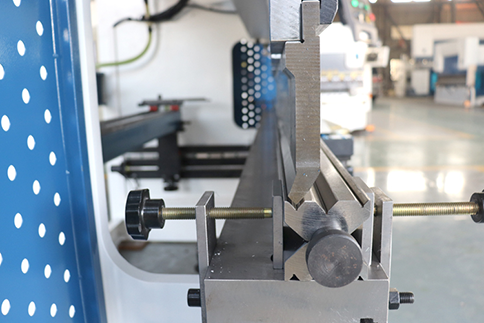

Bending machine mold

The material of the bending machine mold is usually high-strength and high-toughness alloy steel 42CrMo. The notch selection of the mold needs to be determined according to the width 8 times of the plate thickness. It is mainly divided into upper mold and lower mold. The shape and size of the mold are customized according to different work requirements. Common ones include standard U-shaped, V-shaped, bottom mold, upper mold, etc.

1.Standard U-shaped mold: used to manufacture standard bending shapes, suitable for most manual and automatic bending machines.

2.Standard V-shaped mold: has a sharper angle and is suitable for plates that require deeper bends.

3.Bottom form: used for bottom bends, with a folded edge used to shape the sheet in the bottom bend angle.

4.Upper die: used to shape the sheet from the top, usually with right angles and semi-circular shapes.

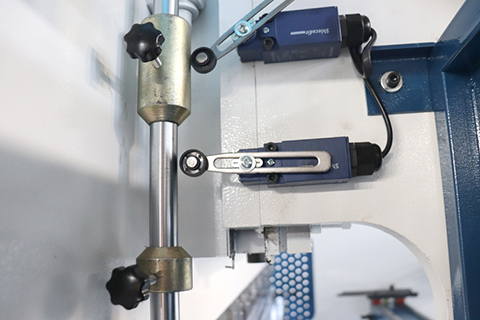

Bending machine travel switch

When the upper and lower molds of the bending machine reach the set positions respectively, the corresponding travel switch will send a signal to notify the hydraulic system to stop movement. The travel switch also helps limit the travel and position control of the workpiece, ensuring that the workpiece is accurately placed at the appropriate bending angle.

Press Brake 2-Axis CNC BackGauge With X, R-Axis

Ball screws and linear guide on X, R-axis

Axis X speed 500 mm/s.

Manual Z1, Z2-axis with HIWIN linear guide.

Mechanical accuracy ± 0.03 mm.

Fingers with double stop and micrometric adjustment.

One-key Release Fast Clamp

The one-key release fast clamp could ensure the safe and fast punch changing, with strict quality requirements and procurement standards of raw materials, which keeps the punch from falling out.

Made of high-quality tool steel/high-strength CrMo alloy steel, the maximum load capacity can reach 800 tons/meter, and the hardness after heat treatment can reach 56~60HRC.

Multifunctional Pedal Switch

JUGAO has upgraded the pedal switch to a new generation, with a single switch design, front-mounted rollers, emergency stop switch, and return button, all for easier and smarter operation.

The multi-function foot switch of the bending machine is an important control device, which allows the operator to achieve precise control of the machine through pedaling movements when operating the bending machine. The design of this switch not only improves the convenience of operation, but also enhances the safety of operation to a great extent.