How to Choose the Right Press Brake Tooling Selection?

Press Brake Tooling Selection is a crucial decision that directly impacts your production efficiency and quality. Choosing the wrong tooling can lead to operational delays, poor precision, and higher costs. In this article, we’ll explore how to make the right selection by understanding the key types of press brake tooling and the best practices to follow for optimal results.

Selecting the appropriate press brake tooling is essential for ensuring accurate bending outcomes and sustaining operational efficiency. This guide provides an in-depth analysis of the fundamental categories of press brake tools, including their components and operational guidelines, to assist you in making well-informed decisions that enhance efficiency and cost-effectiveness.

Introduction

Press brake tooling is a vital component in the metalworking industry, used to bend sheet metal into desired shapes and forms with precision. Whether you’re dealing with simple or intricate bends, the right tooling selection can significantly affect the accuracy, quality, and efficiency of your production process. Choosing the wrong tooling, however, can result in numerous challenges, including increased material waste, longer production times, and compromised product quality. Furthermore, using inappropriate tooling can lead to tooling choices can lead to additional costs for rework, tool replacement, and maintenance.

Understanding the diverse range of press brake tooling, including V-dies, punches, and clamping systems, and selecting the most suitable ones for your specific requirements is crucial for optimizing your production process. The tooling you choose must align with the material type, thickness, bend radius, and machine compatibility. In this article, we will explore the key factors that influence tooling selection and provide guidance on how to choose the right tools for your press brake operations, ensuring both long-term efficiency and cost-effectiveness.

Types of Press Brake Tooling

There are several types of press brake tooling, each serving specific purposes based on your production needs. Let us delve into the most prevalent types:

1. V-Dies (Die Sets)

V-dies are one of the most essential components of press brake tooling. These dies are used to form the bends by holding the material while the punch exerts force. The V-shaped profile of the die determines the bend angle and radius. V-dies come in different sizes and configurations to accommodate various material types and thicknesses.

· Function: Guides and supports the material as it is bent.

· Common Use: Used in almost every metalworking operation, from basic to complex bends.

· Advantages: Simple design, cost-effective, and highly versatile.

2. Punches

Punches are the opposite of dies and are used to apply force to the material during the bending process. Punches come in various shapes and sizes depending on the type of bend required. Common types of punches include single V-punches, multi-V-punches, and hemming punches. Punches are typically used in combination with V-dies to achieve the desired bend.

· Function: Applies force to the material to create a bend.

· Common Use: Used for bending sheet metal in a controlled and precise manner.

· Advantages: Available in various shapes and sizes to suit different materials and bending angles.

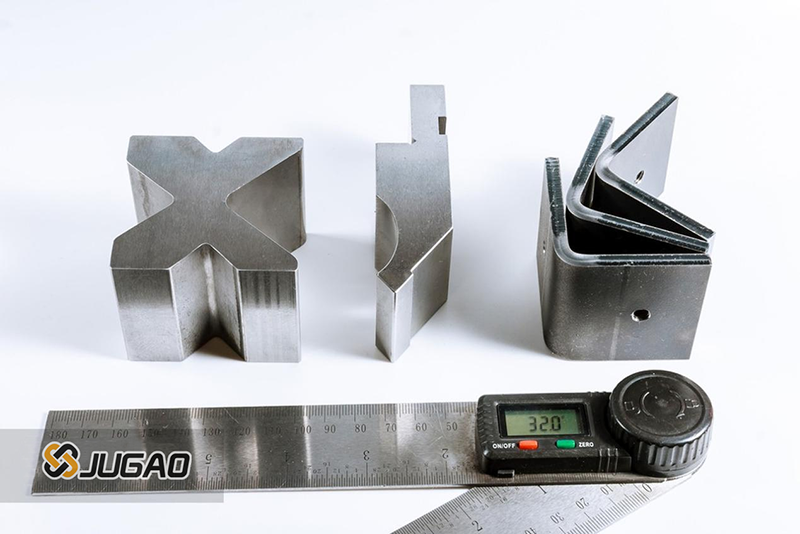

3. Specialty Tooling

Specialty tooling is customized tooling designed to meet specific, complex, or unique bending requirements. This can include tools designed for specific materials (e.g., thicker metals, hard-to-bend materials), or tools for special operations such as punching, notching, or forming intricate shapes.

· Function: Designed to handle specific bending tasks that standard tooling cannot achieve.

· Common Use: For complex or highly specialized applications.

· Advantages: Provides tailored solutions for unique production needs, enhancing flexibility and precision.

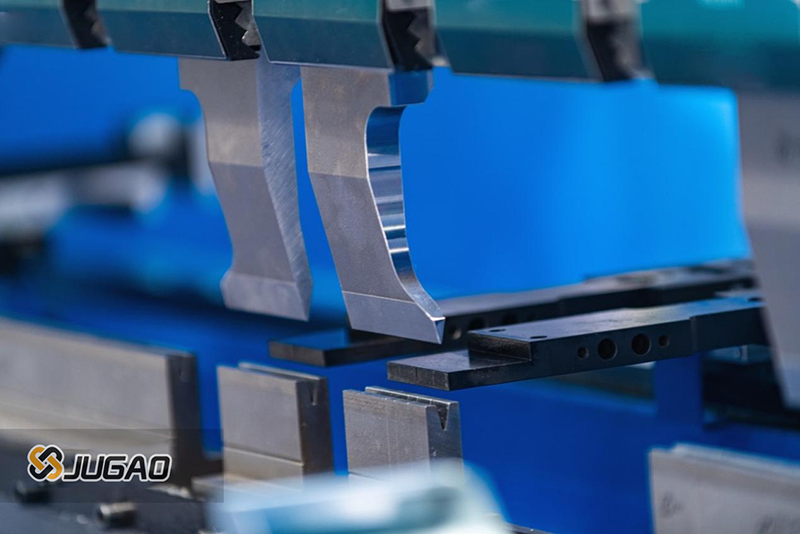

5. Gooseneck Tooling

Gooseneck tooling is used for bending parts with tight inside radii or deep bends. These tools feature a distinct gooseneck shape, allowing the punch to reach areas of the material that are difficult to access with regular tooling.

· Function: Enables tight or deep bends by allowing access to hard-to-reach areas.

· Common Use: Used for complex, high-precision applications such as forming deep bends.

· Advantages: Allows for more flexibility in bending without compromising material integrity.

6. Folding Tooling

Folding tooling is specifically designed for bending sheet metal without creating a significant bend radius. These tools are used in folding operations, where the metal is bent in a way that the material folds over itself, often used for making boxes or enclosures.

· Function: The technology enables a folding motion that maintains structural integrity without creating conventional bends.

· Common Use: Common in box or enclosure making, as well as in the production of parts with no sharp angles.

· Advantages: The automatic feed bending machine, as demonstrated by the new patent from Chengdu Senwo Electric, allows for intricate folds and low-radius bends, significantly improving material efficiency.

Factors to Consider When Choosing Press Brake Tooling

Selecting the right press brake tooling requires a deep understanding of your production needs. Consider the following factors:

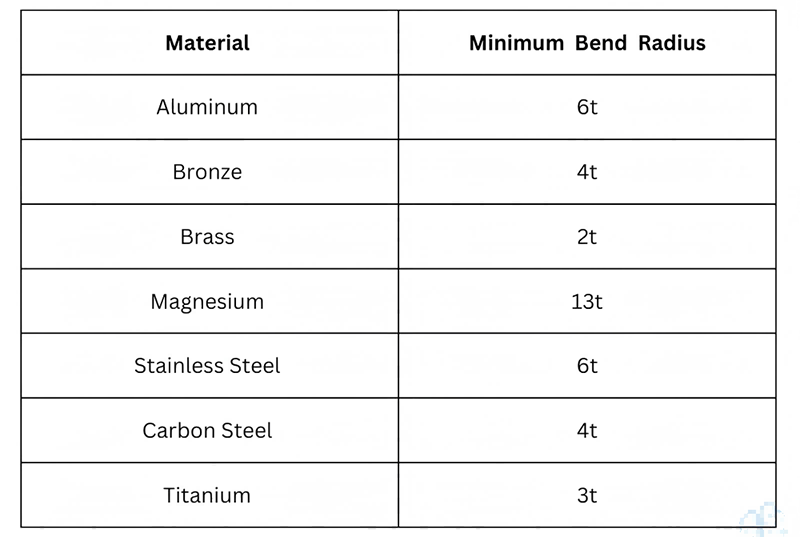

1. Material Type and Thickness

The selection of materials is a critical factor in determining the performance and longevity of press brake tooling, as it influences the tooling's hardness, strength, and wear resistance. Materials such as mild steel, stainless steel, aluminum, and brass exhibit distinct properties that influence their bending behaviors. For instance, stainless steel is known for its high hardness and tendency to spring back, requiring specific tooling with high hardness and surface roughness. Aluminum, on the other hand, offers light weight and high strength, along with good corrosion resistance and weldability, but it can be prone to over-bending due to its softness. The thickness of the material is equally important as it determines the amount of force needed to bend the material.

· Material Type: Some materials are more prone to cracking or may require specialized tooling to handle their properties. For example, stainless steel may need a more robust punch and die system due to its hardness compared to softer materials like aluminum.

· Material Thickness: Thicker materials require stronger tooling that can withstand more force. You may need larger or more durable dies and punches to handle these materials effectively.

Consideration: Always ensure the tooling selected is compatible with the material type and thickness you plan to work with to prevent premature wear and ensure accuracy.

2. Bend Angle and Radius

The bend angle and radius are critical factors that affect the precision of your formed parts. Different tooling types are designed to handle different bend angles and radii. When making your selection, it is essential to consider:

· Bend Angle: Some tooling, such as V-dies, is designed to handle specific bend angles. Ensuring the proper die size and shape will determine the final outcome of the bend.

· Bend Radius: The radius of the bend is equally important. For example, sharp bends require different tooling than gentle or wide-radius bends. Specialty tooling, such as gooseneck tooling, is often used for tight bends.

Consideration: Choose tooling that matches the required bend specifications for the project to ensure clean, accurate bends without material deformation.

3. Tooling Compatibility with Press Brake Machine

Ensuring the tooling you choose is compatible with your press brake machine is essential for smooth operation. Press brakes come in various sizes and types, and not all tooling is designed to fit every machine.

· Machine Specifications: The size of your press brake and its tonnage capacity should align with the tooling you plan to use. For example, a large hydraulic press brake might require larger dies than a smaller mechanical press.

· Machine Control: If you are using a CNC press brake, ensure that your tooling is compatible with the machine’s control system. CNC machines often require more precise tooling, which should be chosen based on the machine’s capabilities.

Consideration: Always check the machine’s specifications to ensure that the tooling is designed to work with your press brake model. This will minimize issues like misalignment and tool wear.

4. Precision and Tolerances

The level of precision required in your bending process will affect your tooling choice. Some projects may demand tight tolerances, while others may allow for more flexibility. CNC press brakes, for instance, are recognized for their high precision, as defined by national standards such as GB/T 14349-2011, which specify the accuracy testing methods and requirements for these machines. The tooling selected must align with these stringent precision standards.

· Tolerances: Stringent tolerances necessitate the use of high-precision tooling capable of maintaining consistent performance over extended periods. Precision tooling often comprises precisely fitting dies and punches, which minimize deviation.

· Material Handling: High-precision tooling is particularly important for thin materials, which may be more prone to damage during bending.

Consideration: If your project demands high accuracy, opt for CNC press brake tooling and specialty dies that ensure tight tolerances and reduce the risk of errors.

5. Tooling Durability and Maintenance

Durability is a key consideration when selecting press brake tooling. High-quality tooling can reduce wear and tear, allowing for a longer lifespan and less frequent replacements. Regular maintenance also plays an essential role in ensuring the long-term effectiveness of tooling.

· Durability: High-quality materials such as high-strength steel and tungsten carbide are known for their exceptional longevity and superior performance in tooling applications. These materials can withstand heavy usage and maintain their cutting edge for extended periods, often lasting several months to years, depending on the specific conditions of use.

· Maintenance Requirements: Tooling should be easy to maintain and clean. Proper care can extend the lifespan of the tooling and reduce costs associated with frequent replacements.

Consideration: Choose durable tooling materials and ensure your team has proper maintenance protocols in place to maximize tool lifespan and performance.

6. Production Volume and Speed

The production volume and required speed of the operation should also influence your tooling selection. For high-volume operations, you may want to consider tooling that is more durable and designed for faster setups and quicker cycle times.

· High-Volume Production: For fast-paced production environments, mechanical or hydraulic press brakes with high-speed tooling may be more suitable. Quick-change dies and punches can also improve productivity.

· Low-Volume or Custom Bending: If you’re working with low-volume or custom jobs, more versatile tooling (such as CNC tooling) may be needed, despite its higher cost, to handle various bending angles and shapes.

Consideration: Match tooling to the volume and speed requirements of your production to avoid bottlenecks and downtime.

7. Cost Efficiency

High-quality tooling, while potentially more expensive upfront, can lead to significant long-term savings by minimizing wear and reducing the frequency of replacements, thus balancing the initial cost with the benefits of durability. Consider the following:

· Initial Cost: Investing in higher-quality tools may entail a greater upfront cost, yet they tend to endure over time, potentially decreasing the frequency of replacements due to their durability.

8. Supplier Reliability and Support

A reputable supplier should offer:

· Technical Support: Having access to expert advice and assistance with tool setup, maintenance, and troubleshooting can significantly reduce downtime.

· Quality Assurance: Ensure that the supplier’s tooling meets industry standards and is backed by warranties or guarantees.

· After-Sales Service: Suppliers who offer responsive after-sales service and prompt replacements for defective tools can help keep your production running smoothly.

Recommendation: Collaborate with suppliers renowned for delivering top-notch tooling and exceptional customer support.

Rules to Follow for Effective Press Brake Tooling Selection

To ensure that your tooling selection leads to efficiency and accuracy, follow these key rules:

· Quality Control: Prioritize tooling that adheres to industry standards, such as ISO 9001 and DIN, to ensure high-quality performance and reliability in manufacturing processes. Well-made tools produce better results and last longer.

· Tooling Maintenance: Proper maintenance is crucial. Regular cleaning, lubrication, and inspection can extend the life of your tools and keep them in peak working condition.

· Supplier Reliability: Choose a reliable supplier with a reputation for delivering quality tooling on time. Communication and after-sales service are critical in preventing production delays.

· Cost Efficiency: While quality remains paramount, it is equally crucial to factor in the overall cost of ownership. Tools of superior quality, which enjoy a longer lifespan, may ultimately provide greater value than their less expensive counterparts.

How to Maintain Your Press Brake Tooling

Regular maintenance is essential for maximizing the life of your press brake tooling. Here are some tips:

1. Regular Cleaning

Keeping your tooling clean is the first and most important step in maintaining its performance. Dirt, dust, and debris can cause uneven wear, affect the accuracy of the bends, and even damage the tooling. Cleaning should be done after each production run to prevent buildup.

· Action: Use a soft cloth or brush to wipe down the dies, punches, and clamping systems. Avoid using abrasive materials that could scratch or damage the surface of the tools.

· Why it Matters: Regular cleaning prevents the buildup of metal shavings and other contaminants, which can degrade tooling and diminish its effectiveness.

2. Lubrication

Proper lubrication aids in reducing friction between tooling and the material being bent, minimizing wear and tear. Additionally, it ensures smooth operation by facilitating easy gliding of dies and punches, thereby enhancing bending accuracy.

· Action: Apply a light coat of lubrication to the surfaces of the dies, punches, and clamping systems as part of your routine maintenance schedule. Use lubricants that are specifically designed for press brake operations.

· Why it Matters: Lubrication reduces friction, extending the life of your tooling, and preventing excessive heat buildup, which could cause tool deformation or failure.

3. Inspect for Wear and Damage

Routine inspection of your press brake tooling is necessary to catch early signs of wear or damage. Over time, tooling may develop signs of wear, such as chipped edges, cracks, or deformed areas, especially after prolonged use in high-volume production.

· Action: Regularly check the tooling for visible signs of wear, such as uneven surfaces, nicks, or cracks. Pay particular attention to the edges of the dies and the punch faces, as these areas are most prone to wear.

· Why it Matters: Early identification and mitigation of tool wear are crucial to prevent significant damage to the tooling and to maintain consistent production quality, as detailed in machining studies. Worn tooling can lead to inaccurate bends and reduced product quality.

4. Ensure Proper Storage

Proper storage of tooling when not in use is crucial for preventing damage, rust, or deformation. Storing tools improperly can result in warping or rust buildup, especially when exposed to moisture or extreme temperatures.

· Action: Store tooling in a dry, temperature-controlled environment. Use tool racks, cabinets, or protective covers to prevent tools from being scratched, chipped, or exposed to harmful elements. Additionally, store heavier tooling on shelves that can support the weight to avoid any bending or warping.

· Why it Matters: Proper storage ensures that your tools remain in good shape when needed and prevents preventable damage or corrosion.

5. Check Tool Alignment

Proper alignment of the tooling is critical for achieving precise and accurate bends. Misaligned dies or punches can lead to product defects, including inaccurate angles, inconsistent bends, or even tool damage, which can be quantified and assessed through defect rate calculations.

· Action: Before starting a new production run, check the alignment of the tooling on the press brake machine. Make sure that the dies are properly seated in the machine and that the punch and die are aligned correctly to avoid any misalignment during bending.

· Why it Matters: Correct alignment ensures that the tooling applies force evenly across the material, which improves the quality and precision of the bends.

6. Monitor Tooling Performance

Over time, tooling performance may degrade slightly due to prolonged use. Real-time monitoring of tooling performance during production, as suggested by Reference 0, can facilitate early detection of issues and enable corrective actions before problems escalate, enhancing quality control and operational efficiency.

· Action: Monitor the press brake during operation for signs of unusual noise, vibration, or difficulty in bending. These could be early warning signs that the tooling needs maintenance or replacement.

· Why it Matters: Timely detection of performance issues helps prevent production delays and ensures that the tooling continues to work efficiently, minimizing downtime.

Conclusion

Selecting appropriate press brake tooling is essential for ensuring the precision and superior quality of the bending process. By understanding the different types of tooling, considering key factors like material type and machine compatibility, and following best practices for maintenance, you can optimize your production process. If you’re unsure about the best tooling options for your needs, reach out to a trusted supplier for expert advice.

About Gary Olson

Gary Olson is a skilled website editor at JUGAO CNC MACHINE, specializing in curating and organizing professional knowledge about sheet metal processing. With a keen eye for detail and a passion for precision, He ensures that all technical content is accurate, engaging, and informative. Gary Olson regularly updates the JUGAO website with invaluable industry insights, helping to educate and support customers and professionals in the metalworking field. His dedication to excellence plays a key role in strengthening JUGAO's online presence and reputation as a trusted authority in sheet metal solutions.View all posts by Gary Olson