How Do Digital Controls Enhance Press Brakes?

Digital controls are essential for improving the precision, efficiency, and ease of use when operating press brakes. Integrating these controls can greatly enhance the overall performance of your machine. In this article, I will explain how digital controls can elevate the functionality of press brakes, making them more intuitive and increasing the accuracy of your metalworking projects. Whether you’re an experienced operator or a beginner, understanding digital controls will help you maximize your machine’s potential.

What Are Digital Controls for Press

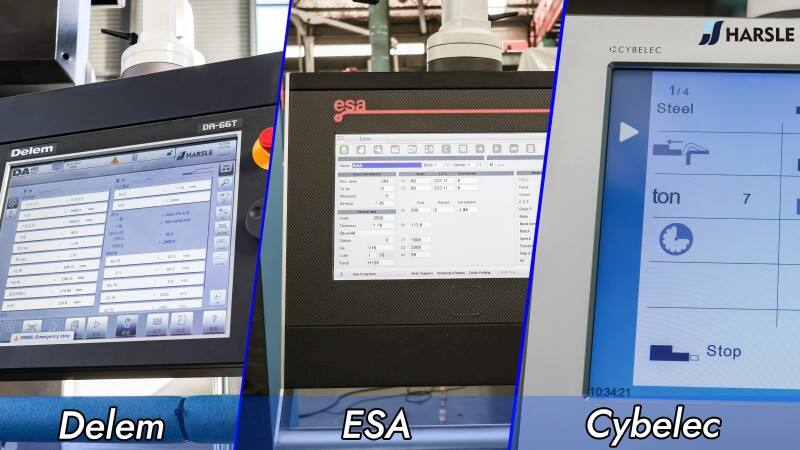

Digital controls refer to the computerized systems installed on press brakes that help operators manage and monitor various aspects of the machine’s operation. These controls allow for precise adjustments to bending parameters, tool setup, and machine movements, all of which contribute to improved accuracy and efficiency. Unlike traditional mechanical systems, digital controls provide real-time data and feedback, enabling users to make fine-tuned adjustments with ease.

Benefits of Digital Controls for Press Brakes

Enhanced Precision in Bending

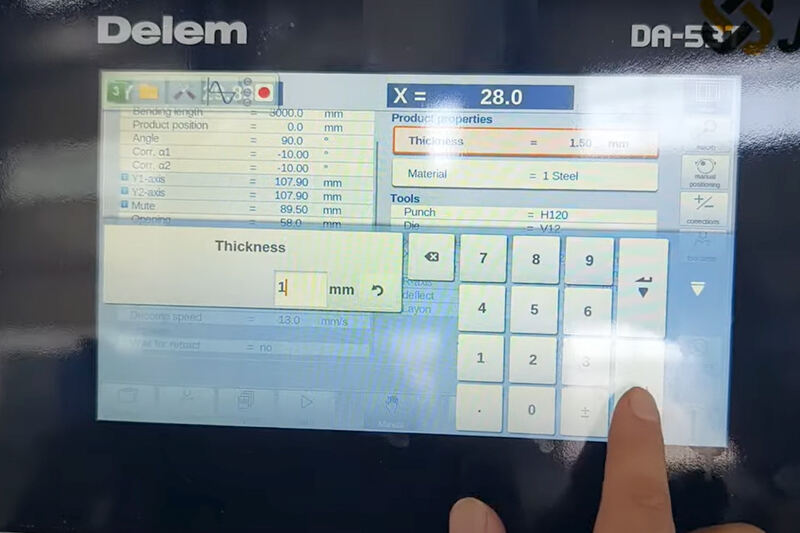

One of the key advantages of digital controls is their ability to improve the precision of bends. By inputting specific measurements into the system, operators can achieve exact angles and dimensions. This eliminates the need for manual calculations, reducing human error and ensuring the final product matches specifications.

Increased Efficiency and Reduced Setup Time

With digital controls, setting up your press brake becomes a quicker and more efficient process. The system allows operators to store preset bending programs for different jobs, enabling fast setup changes. Instead of manually adjusting the machine for each task, the system can automatically adjust the parameters, reducing downtime and increasing overall productivity.

Easy Integration with Other Systems

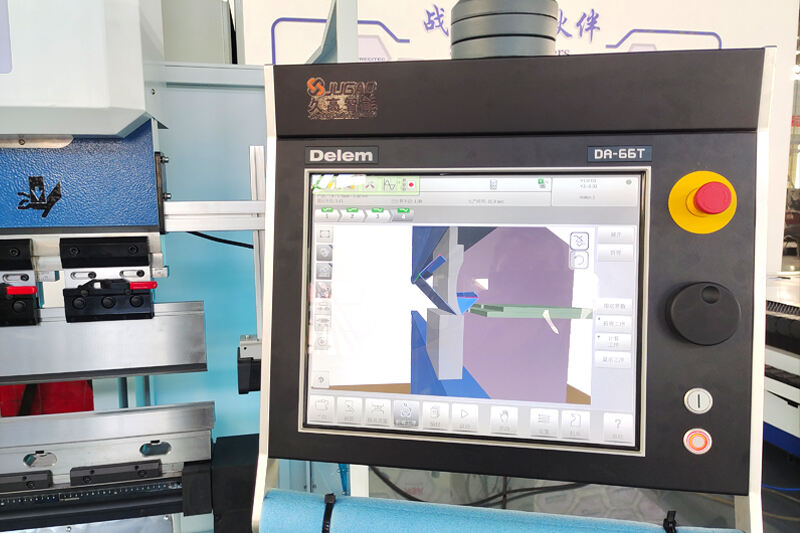

Digital controls on press brakes can be integrated with other systems like CAD/CAM software, allowing for seamless workflow across different stages of production. This integration helps streamline the manufacturing process, making it easier to manage complex designs and adjust settings directly from the digital interface.

Real-Time Monitoring and Diagnostics

Digital controls provide operators with real-time data on the performance of the press brake. This includes monitoring of parameters like pressure, speed, and position. If something goes wrong, the system can quickly diagnose issues, alerting operators to any malfunctions or areas that need attention. This proactive approach helps prevent major breakdowns and minimizes machine downtime.

How Digital Controls Improve the User Experience

Simplified User Interface

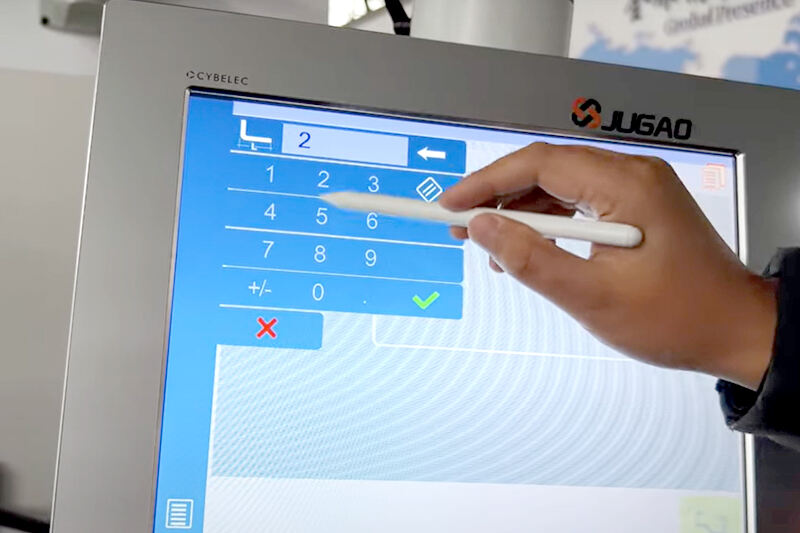

Digital controls come with user-friendly interfaces, often featuring touchscreens that display intuitive menus and instructions. This makes it easier for operators, especially those who are new to press brakes, to navigate the machine’s functions. The interface typically includes clear visuals and helpful prompts that guide users through setup and operation, reducing training time and errors.

Enhanced Customization

With digital controls, users can easily customize settings based on the specific requirements of each project. This flexibility allows press brakes to handle a variety of tasks, from simple bends to complex shapes. By adjusting settings like speed, pressure, and angle, operators can fine-tune the machine for optimal results on different materials.

FAQ

How do I set up digital controls on my press brake?

Setting up digital controls on your press brake involves entering the correct bending parameters into the system. This may include selecting the material type, thickness, and desired bend angle. Once inputted, the system will automatically adjust the machine’s settings to ensure the highest level of precision.

Can digital controls be used for all press brake models?

Most modern press brake models are compatible with digital control systems. However, older models may require retrofitting to accommodate digital controls. It’s important to consult the manufacturer or a professional technician to determine compatibility.

What happens if the digital control system malfunctions?

If the digital control system malfunctions, it will usually provide an error message or diagnostic information to help identify the issue. You can troubleshoot by following the instructions provided in the machine’s manual or contact the manufacturer for support.

Conclusion

Digital controls play a vital role in enhancing the performance of press brakes by improving precision, efficiency, and ease of use. By integrating digital systems into your press brake operations, you can streamline production processes, reduce setup time, and achieve greater accuracy in your bends. For more information on digital controls or support with your press brake, feel free to reach out to JUGAO CNC MACHINE our team today.

How Do Digital Controls Enhance Press Brakes?

Table of contents

· What Are Digital Controls for Press Brakes?

· Benefits of Digital Controls for Press Brakes

· Enhanced Precision in Bending

· Increased Efficiency and Reduced Setup Time

· Easy Integration with Other Systems

· Real-Time Monitoring and Diagnostics

· How Digital Controls Improve the User Experience

· Simplified User Interface

· Enhanced Customization

· FAQ

· How do I set up digital controls on my press brake?

· Can digital controls be used for all press brake models?

· What happens if the digital control system malfunctions?

· Conclusion

Digital controls are essential for improving the precision, efficiency, and ease of use when operating press brakes. Integrating these controls can greatly enhance the overall performance of your machine. In this article, I will explain how digital controls can elevate the functionality of press brakes, making them more intuitive and increasing the accuracy of your metalworking projects. Whether you’re an experienced operator or a beginner, understanding digital controls will help you maximize your machine’s potential.

What Are Digital Controls for Press Brakes?

Digital controls refer to the computerized systems installed on press brakes that help operators manage and monitor various aspects of the machine’s operation. These controls allow for precise adjustments to bending parameters, tool setup, and machine movements, all of which contribute to improved accuracy and efficiency. Unlike traditional mechanical systems, digital controls provide real-time data and feedback, enabling users to make fine-tuned adjustments with ease.

Benefits of Digital Controls for Press Brakes

Enhanced Precision in Bending

One of the key advantages of digital controls is their ability to improve the precision of bends. By inputting specific measurements into the system, operators can achieve exact angles and dimensions. This eliminates the need for manual calculations, reducing human error and ensuring the final product matches specifications.

Increased Efficiency and Reduced Setup Time

With digital controls, setting up your press brake becomes a quicker and more efficient process. The system allows operators to store preset bending programs for different jobs, enabling fast setup changes. Instead of manually adjusting the machine for each task, the system can automatically adjust the parameters, reducing downtime and increasing overall productivity.

Easy Integration with Other Systems

Digital controls on press brakes can be integrated with other systems like CAD/CAM software, allowing for seamless workflow across different stages of production. This integration helps streamline the manufacturing process, making it easier to manage complex designs and adjust settings directly from the digital interface.

Real-Time Monitoring and Diagnostics

Digital controls provide operators with real-time data on the performance of the press brake. This includes monitoring of parameters like pressure, speed, and position. If something goes wrong, the system can quickly diagnose issues, alerting operators to any malfunctions or areas that need attention. This proactive approach helps prevent major breakdowns and minimizes machine downtime.

How Digital Controls Improve the User Experience

Simplified User Interface

Digital controls come with user-friendly interfaces, often featuring touchscreens that display intuitive menus and instructions. This makes it easier for operators, especially those who are new to press brakes, to navigate the machine’s functions. The interface typically includes clear visuals and helpful prompts that guide users through setup and operation, reducing training time and errors.

Enhanced Customization

With digital controls, users can easily customize settings based on the specific requirements of each project. This flexibility allows press brakes to handle a variety of tasks, from simple bends to complex shapes. By adjusting settings like speed, pressure, and angle, operators can fine-tune the machine for optimal results on different materials.

FAQ

How do I set up digital controls on my press brake?

Setting up digital controls on your press brake involves entering the correct bending parameters into the system. This may include selecting the material type, thickness, and desired bend angle. Once inputted, the system will automatically adjust the machine’s settings to ensure the highest level of precision.

Can digital controls be used for all press brake models?

Most modern press brake models are compatible with digital control systems. However, older models may require retrofitting to accommodate digital controls. It’s important to consult the manufacturer or a professional technician to determine compatibility.

What happens if the digital control system malfunctions?

If the digital control system malfunctions, it will usually provide an error message or diagnostic information to help identify the issue. You can troubleshoot by following the instructions provided in the machine’s manual or contact the manufacturer for support.

Conclusion

Digital controls play a vital role in enhancing the performance of press brakes by improving precision, efficiency, and ease of use. By integrating digital systems into your press brake operations, you can streamline production processes, reduce setup time, and achieve greater accuracy in your bends. For more information on digital controls or support with your press brake, feel free to reach out to our team today.