Efficient and accurate production line for oil storage tanks

Jan.25.2024

In today's industrial production, efficient and precise production lines are the key to manufacturing high-quality products. This video shows us the production process of oil storage tanks, air storage cylinders, and water tanks. The production line mainly consists of 4 pieces of equipment, namely plasma cutting machine, edge spinning machine, plate rolling machine, and automatic welding machine. Below, we will introduce each step of this production line in detail.

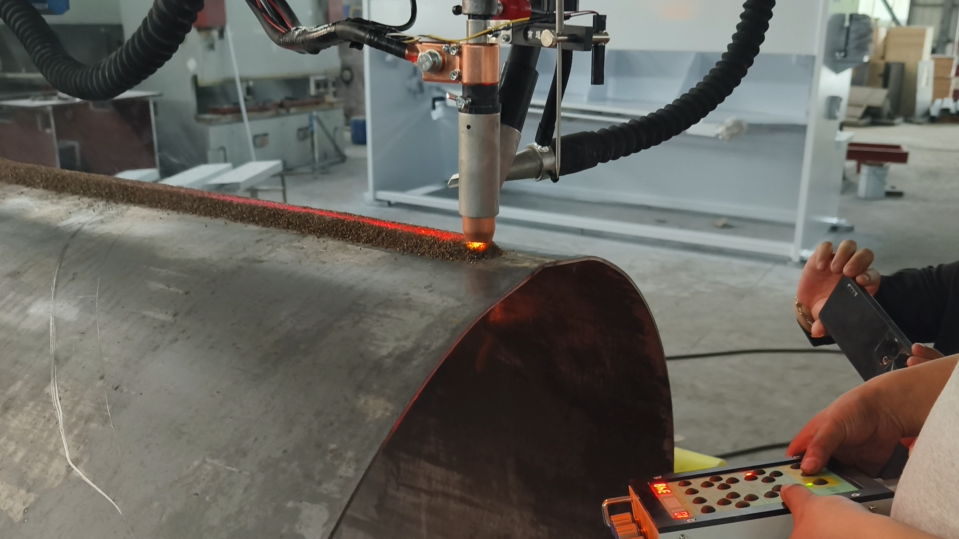

1: Plasma cutting

Plasma cutting is the first step in the production line. Plasma cutting machines use high-temperature plasma gas to cut steel plates into circles. This cutting method has high precision and smooth cutting edges, laying a solid foundation for subsequent processing steps.

2: Edge spinning machine

The edge turning machine is the second step in the production line. The edge turning machine flanges the edges of the circular steel plate to make the steel plate stronger and more beautiful. This step ensures the strength and stability of the product.

Efficient and accurate production line for oil storage tanks

gas cylinders and water tanks

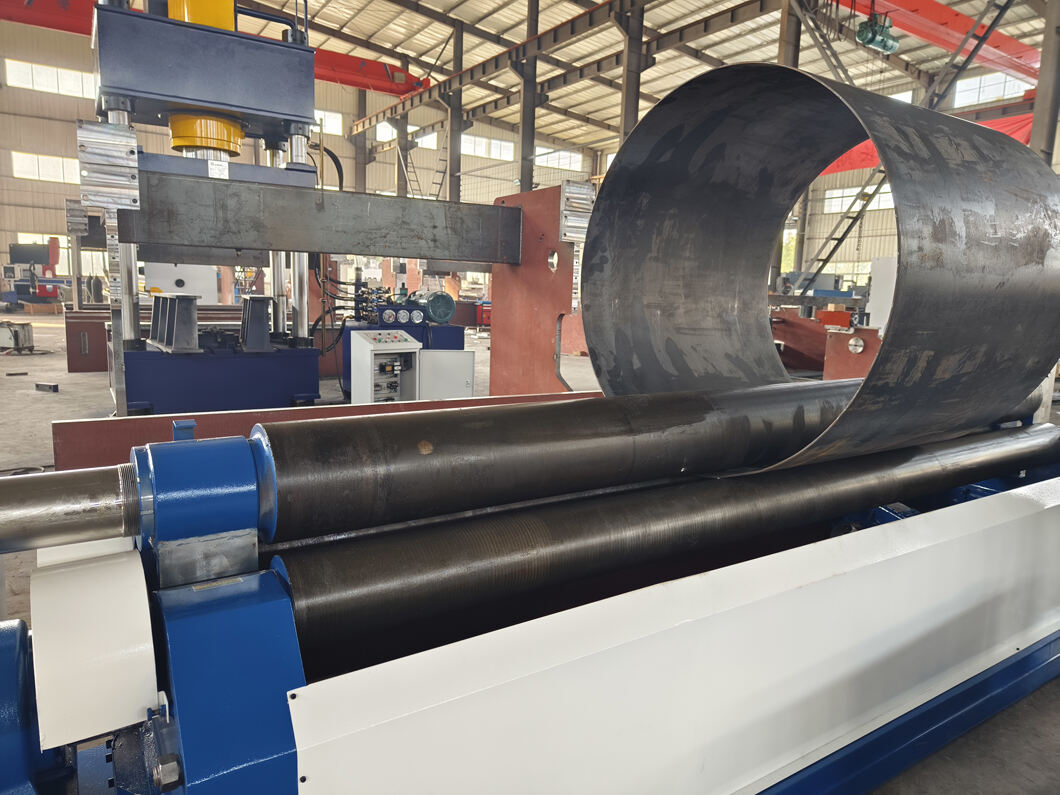

3: Plate rolling machine

The plate rolling machine is the third step in the production line. The plate rolling machine rolls steel plates into cylindrical products, which is a key step in manufacturing oil storage tanks, air storage cylinders, and water tanks. The accuracy and stability of the plate rolling machine directly affect the quality and performance of the product.

4 automatic welding machine

The automatic welding machine is the last step in the production line. The automatic welding machine can automatically weld the straight seam and bottom seam of cylindrical products. This welding method is fast and of high quality, which greatly improves production efficiency.

Through each step of this production line, we can see an efficient and precise production process. From plasma cutting to automatic welding, every link is strictly controlled to ensure product quality and performance. Finally, after a series of processing and welding, we obtained high-quality oil storage tanks, air storage cylinders, and water tank products.

This production line demonstrates the advanced technology and high efficiency of modern industrial production. Through plasma cutting, spinning, plate rolling and automatic welding, we are able to manufacture high-quality oil storage tanks, air storage cylinders, and water tank products. The application of this production line not only improves production efficiency, but also ensures product quality and performance. We believe that with the continuous development of science and technology, such production lines will play a greater role in the future and bring more innovations and breakthroughs to our industrial production.