Calculate the Press Brake Tonnage for Any Part

Every time you need to bend a new part, think: “Do we have enough tonnage to bend this?” To bend sheet metal is to disrupt the molecular structure of the metal. At least enough power needs to be provided to achieve "plastic deformation". Unlike elastic deformation, this type of deformation is irreversible because the molecular structure changes. Our bending solution calculator can be of great help when trying to calculate the tonnage required to bend metal to achieve plastic deformation.

"Plastic deformation" and "elastic deformation"

While ED (elastic deformation) allows the material to return to its original shape, PD (plastic deformation) means that some of the fibers of our material have changed its structure, so the material does not fully return to its original shape. PD is basically what we want to achieve when bending on a press brake. It is sometimes difficult to tell with the naked eye whether PD has been achieved.

Required tonnage rate of bending machine

When calculating the tonnage required to bend a material, A: Tonnage rate, which is tons/foot or tons/meter. B: Length of bent metal plate.

Simple example:

We need to bend 1.5 meters of ¼ mild steel.

We will use a V opening of 50mm (about 2).

We will apply 85 tons… which means about 56 tons/meter.

This rate will, in fact, bend the material, but let’s think about the following:

Q) What would happen if we change the length to 3 meters?

A) If we continue to apply 85 tons we will be applying about 28 tons/meter.. so our material will not bend.

Q) What would happen if we change the length to 0.5 meters?

A) If we continue to apply 85 tons we will be applying about 170 tons/meter.. which will probably damage our tooling and our press brake.

But how do we determine the required ton/meter rate?

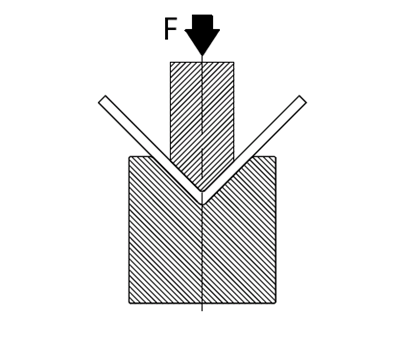

Mathematics and engineering have provided for us an equation that we can use to find the maximum load (or tonnage).

The Formula

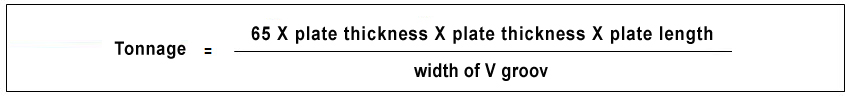

Tonnage = (65X plate thickness X plate thickness X plate length) / width of V groove

1. Plate thickness: The greater the thickness of the plate, the greater the tonnage required.

2. Plate length: The longer the plate length, the greater the required tonnage.

3. The width of the V-groove: usually 8-10 times the plate thickness. The larger the V-groove is, the smaller the required tonnage is, but the larger the R angle of the bent workpiece is. On the contrary, the smaller the V-groove, the greater the tonnage required, but the smaller the R angle of the bent workpiece.

4. 65: Bending coefficient. This coefficient is calculated based on the standard carbon plate strength of 500N/mm².

Example:

Take an ordinary carbon plate with a plate thickness of 2mm and a length of 2500mm as an example.

Tonnage=(65 x 2 x 2 x 2.5)/(2 x 8)=40.6TON.

You can choose a 40TON/2500 bending machine for processing.