- Oorsig

- Vraag

- GERELEERDE PRODUKTE

Produk Kenmerke

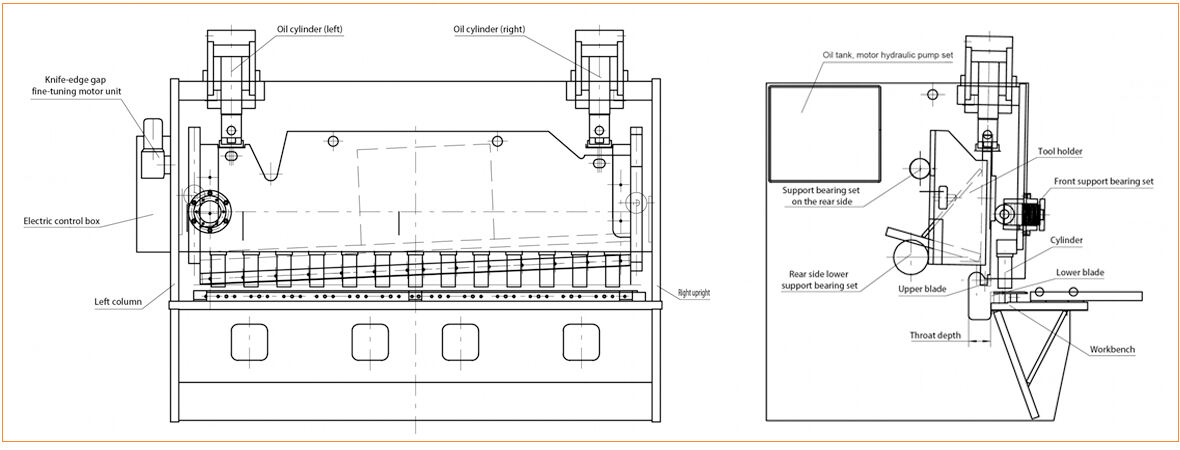

1.Snyhoek kan aangepas word. Dit word gebruik om metaalblaaie van verskillende materialen te sny. Om snykwaliteit te verseker.

2. Vier kante van die blaar kan gebruik word. Dus is die dienslewen van die blaar dubbel soveel as van gewone masjiene.

3. Elektriese blaar randopening aanpassing. Eenvoudiger bediening.

4. Die opwaartse beweging van die blaar word deur 'n akkumulator beheer. Geen noodsaaklikheid om in die toekoms stikstofgas by te voeg nie.

5. Sny van staalplaat met dikte groter as 12mm. Die snykwaliteit is beter.

Voorbeeld wysing

Tegniese parameter

| Nee | Model | Maks snydikte (mm) | Maks snylengte (mm) | Ramslag (n/min) | Snyhoek (°) | Motor (kw) | Masjienformaat (mm) |

| 1 | 4x2500 | 4 | 2500 | 20-40 | 0.5-1.5 | 5.5 | 3100x1600x1700 |

| 2 | 4x3200 | 4 | 3200 | 20-40 | 0.5-1.5 | 7.5 | 3800x1800x1700 |

| 3 | 6x2500 | 6 | 2500 | 16-35 | 0.5-1.5 | 7.5 | 3150x1650x1700 |

| 4 | 6x3200 | 6 | 3200 | 14-35 | 0.5-1.5 | 7.5 | 3860x1810x1750 |

| 5 | 6x4000 | 6 | 4000 | 10-30 | 0.51.5 | 7.5 | 4630x2030x1940 |

| 6 | 6x5000 | 6 | 5000 | 10-30 | 0.5-1.5 | 11 | 5660x2050x1950 |

| 7 | 6x6000 | 6 | 6000 | 8-25 | 0.5-1.5 | 11 | 6680x2200x2500 |

| 8 | 8x2500 | 8 | 2500 | 14-30 | 0.5-1.5 | 11 | 3170x1700x1700 |

| 9 | 8x3200 | 8 | 3200 | 12-30 | 0.5-1.5 | 11 | 3870x1810x1780 |

| 10 | 8x4000 | 8 | 4000 | 10-25 | 0.5-1.5 | 11 | 4680x1900x1860 |

| 11 | 8x5000 | 8 | 5000 | 10-25 | 0.5-1.5 | 15 | 5680x2250x2200 |

| 12 | 8x6000 | 8 | 6000 | 8-20 | 0.5-1.5 | 15 | 6800x2350x2700 |

| 13 | 10x2500 | 10 | 2500 | 10-25 | 0,5-2,0 | 15 | 3270x1730x1800 |

| 14 | 10x3200 | 10 | 3200 | 9-25 | 0,5-2,0 | 15 | 3990x2250x2200 |

| 15 | 10x4000 | 10 | 4000 | 6-20 | 0,5-2,0 | 15 | 4720x2490x2500 |

| 16 | 10x5000 | 10 | 5000 | 7-20 | 0,5-2,0 | 22 | 5720x2600x2800 |

| 17 | 10x6000 | 10 | 6000 | 6-20 | 0,5-2,0 | 30 | 6720x2500x2550 |

| 18 | 12x2500 | 12 | 2500 | 10-25 | 0,5-2,0 | 15 | 3270x1730x1800 |

| 19 | 12x3200 | 12 | 3200 | 9-25 | 0,5-2,0 | 15 | 3990x2250x2200 |

| 20 | 12x4000 | 12 | 4000 | 6-20 | 0,5-2,0 | 15 | 4720x2490x2500 |

| 21 | 12x5000 | 12 | 5000 | 7-20 | 0,5-2,0 | 22 | 5720x2600x2800 |

| 22 | 12x6000 | 12 | 6000 | 6-20 | 0,5-2,0 | 30 | 6720x2500x2550 |

| 23 | 12x7000 | 12 | 7000 | 6-20 | 0,5-2,0 | 37 | 7800x2600x3200 |

| 24 | 12x8000 | 12 | 8000 | 6-20 | 0,5-2,0 | 45 | 9100x2800x3400 |

| 25 | 12x10000 | 12 | 10000 | 4-18 | 0,5-2,0 | 55 | 11100x3200x3900 |

| 26 | 12x12000 | 12 | 12000 | 4-18 | 0,5-2,0 | 2X37 | 13200x3950x4800 |

| 27 | 16x2500 | 16 | 2500 | 9-20 | 0.5-2.5 | 22 | 3320x2100x2200 |

| 28 | 16x3200 | 16 | 3200 | 8-20 | 0.5-2.5 | 22 | 4120x2150x2300 |

| 29 | 16x4000 | 16 | 4000 | 8-15 | 0.5-2.5 | 22 | 4760x1900x2560 |

| 30 | 16x5000 | 16 | 5000 | 7-15 | 0.5-2.5 | 30 | 5760x2200x2750 |

| 31 | 16x6000 | 16 | 6000 | 6-15 | 0.5-2.5 | 37 | 6880x2480x3000 |

| 32 | 16x8000 | 16 | 8000 | 5-15 | 0.5-2.5 | 55 | 9120x3000x3800 |

| 33 | 16x10000 | 16 | 10000 | 4-15 | 0,5-3,0 | 2X37 | 11200x3400x4000 |

| 34 | 16x12000 | 16 | 12000 | 3-12 | 0,5-3,0 | 2x45 | 13300x4300x5800 |

| 35 | 20x2500 | 20 | 2500 | 7-20 | 0,5-3,0 | 30 | 3300x2050x2440 |

| 36 | 20x3200 | 20 | 3200 | 6-20 | 0,5-3,0 | 30 | 4000x2160x2540 |

| 37 | 20x4000 | 20 | 4000 | 5-15 | 0,5-3,0 | 30 | 4930x2300x2710 |

| 38 | 20x5000 | 20 | 5000 | 4-15 | 0,5-3,0 | 55 | 5860x2400x3150 |

| 39 | 20x6000 | 20 | 6000 | 4-15 | 0,5-3,0 | 55 | 6100x2650x3375 |

| 40 | 20x8000 | 20 | 8000 | 4-15 | 1,0-2,5 | 2X37 | 9120x3400x3800 |

| 41 | 20x10000 | 20 | 10000 | 4-14 | 1,0-2,5 | 2x45 | 11200x4300x5800 |

| 42 | 20x12000 | 20 | 12000 | 3-12 | 1,0-2,5 | 2x55 | 13380x4500x6100 |

| 43 | 25x2500 | 25 | 2500 | 6-15 | 1.0-3.5 | 37 | 3300x2000x2650 |

Lys van toerustingmerke

OPITION PART