- Overview

- Inquiry

- Related Products

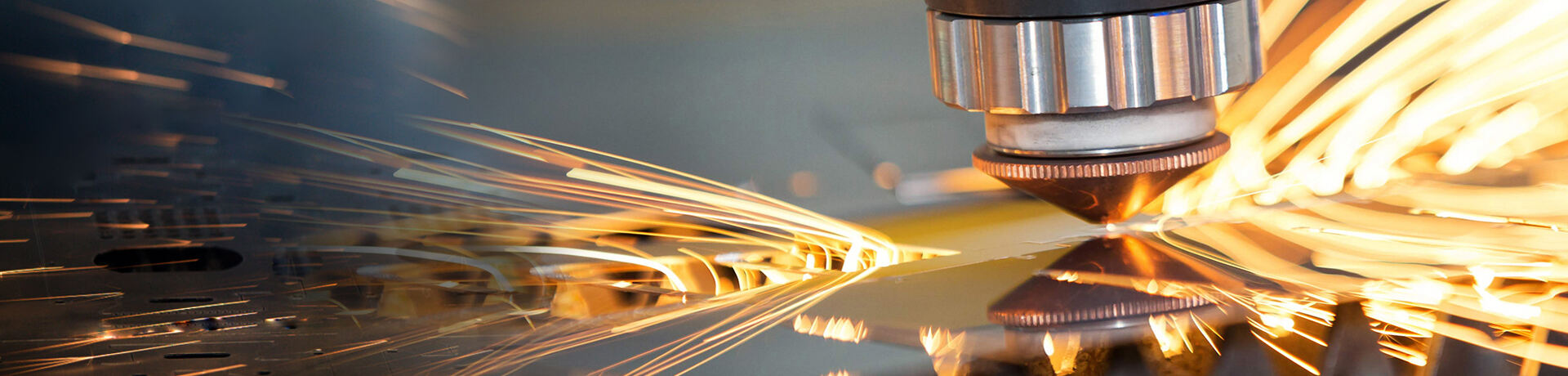

100% Fully-electric press brake for simple to complex sheet metal bending.German lF brand screw rod ball screw press brake is driven by an AC servo motorand ball screw drive mechanism.lt maximizes productivity with high speed ramand high precision repeatability(0.01mm). This drive method is quiet in operation.which results in cost savings at the same time.

The pure electric servo press brake automatically outputs the appropriate power according to the working conditions, without the use and replacement of hydraulic oil, avoiding the pollution of the waste liquid pressure oil to the environment.

Compared with electro-hydraulic press brakes, it can save more than 60% of energy, reduce operating costs, and increase efficiency by more than 40%, thus becoming a more stable and reliable choice.

Currently, we offer these highly sophisticated eco-friendly electric servo press brakes in multiple sizes. They can be configured to handle various stroke lengths and force/load requirements to meet the needs of any production process.

CONTROLLER

The new generation DA-Touch controlsoffers an even higher grade of efficiency inprogramming, operation and control oftoday's press brakes, Ease of usecombined with state-of-the-art technologygo hand in hand, improving productivity

The DA-69T offers 2D as well as 3Dprogramming that includes automaticbend sequence calculation and collisiondetection. Full 3D machine set-up withmultiple tool stations giving true feedbackon the product feasibility and handling

Highly effective control algorithmsoptimise the machine cycle andminimise set-up time. This makes usingpress brakes easier, more efficient andmore versatile then ever.

The OEM-panel located above the screenreserved for machine functions and OEM-application switches, is integrated in thedesign and can be used depending therequired application.

Design Concept:

Our Servo-Electric Press Brake provides energy savings of up to 50%.

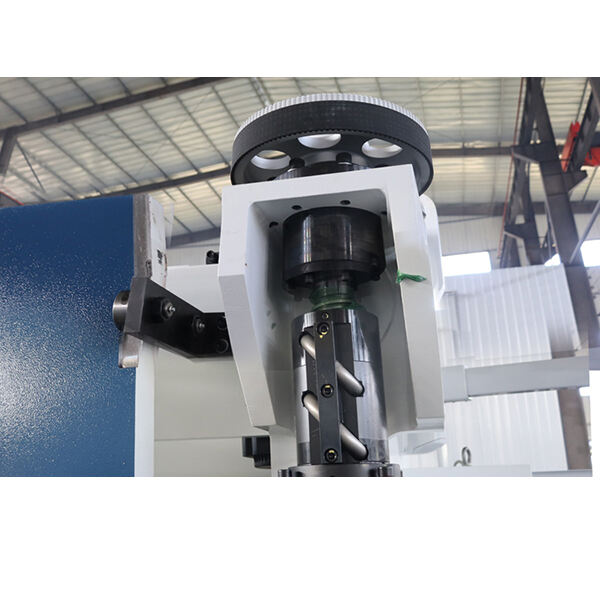

Electric press brake machine is a compact, fast, accurate, non-hydraulic bending solution. The ram is driven by a heavy-duty servo motor and a high-performance ball screw. This innovative machine concept combines productivity, accuracy, flexibility, and reliability with high priority to beneficial ecological aspects.

Advantages:

Noiseless All-electric Servo

No Hydraulic Oil or Hydraulic Filter

No Valves or Cylinders

No Clutch or Flywheel

Reduced Dwell Time

Press Brake Machine Frame Structure

1.Machine frame is of steel welding structure through finite element analysis and optimal design, featuring hi-rigidity and strength.

2.Welding stress is deleted after the annealing treatment for welding parts in the electric furnace, which can avoid the frame deformation in future. Sandblasting remove the rust on the welding parts and the anti-rust painting apply to the welding structure parts.

3.Heat Treatment Processes:JUGAO press brake and laser cutting machine steel frames undergo annealing at over 600⁰ to relieve stress and they are built to last years of heavy use without distortion.

Mechanical compensation workbench (V axis)

Mechanical deflection compensation with high CNC precision is adopted. Since there are many compensation points, the bending machine can realize linear compensation when bending the workpiece during operation, which can improve the bending effect of the workpiece. It has the characteristics of maintenance-free and more accurate compensation

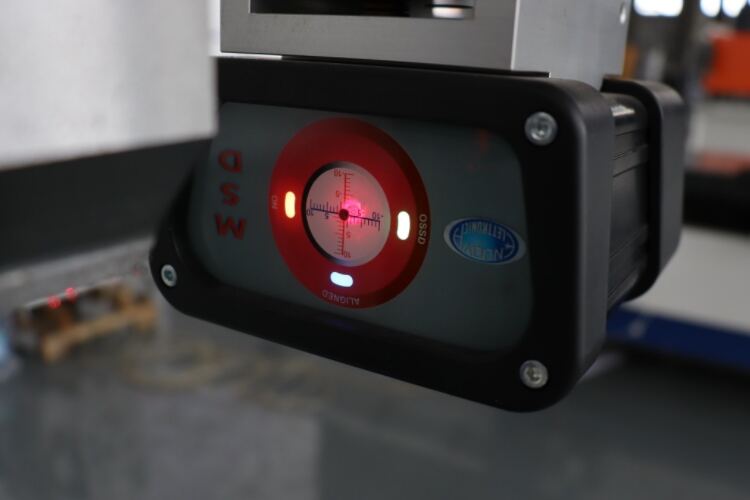

High precision grating ruler

Y1,Y2 axes are two independent CNC axes of two oil cylinders. The linear scale will measure the distance between ram and worktable.Its data will feed back to the control, and after close-loop calculation the servo valve signals S1 and S2 are output to control the output flow of two servo valves. A high-precision grating ruler is used as the displacement sensor, which is installed on the C-shaped plate to detect the position of the oil cylinder. The feedback accuracy is as high as 0.001mm, which can help better control the bending angle.

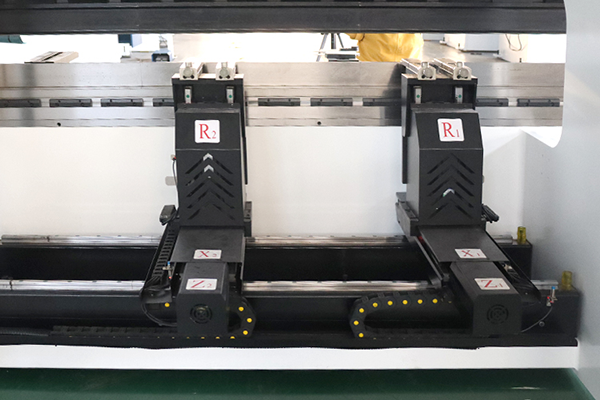

CNC Backgauge

Up to 8-axis controlling CNC backgauge guarantees the flexible bending as customers’ requirements. High accuracy with precision ball screws and linear guide.Supports Y1Y2, The Y1Y2 axis is responsible for controlling the bending angle and shape to achieve the bending of workpieces with different cross-sectional shapes. The R1R2 axis is used to adjust the working height of the bending machine, and the Z1Z2 axis is used to position the plate width to adapt to metal plates of different widths.

One-key Release Fast Clamp

The one-key release fast clamp could ensure the safe and fast punch changing, with strict quality requirements and procurement standards of raw materials, which keeps the punch from falling out.

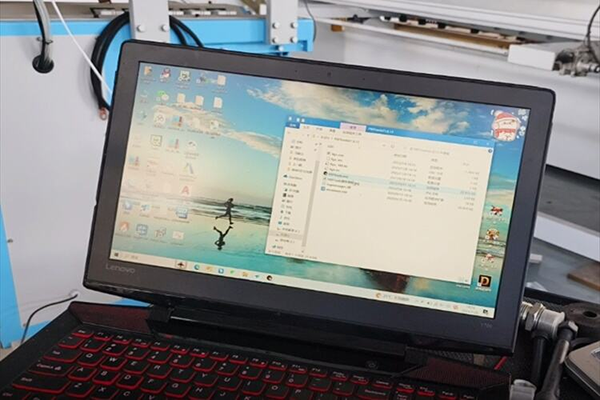

Offline Software

The Profile-T3D software makes possible the offline programming and simulation of the bending process. It is software on any remote computer and it maximizes the efficiency and production output of the JUGAO press brake.

Multifunctional Pedal Switch

JUGAO has upgraded the pedal switch to a new generation, with a single switch design, front-mounted rollers, emergency stop switch, and return button, all for easier and smarter operation.