- Overview

- Inquiry

- Related Products

CONTROLLER

Customize The Controller For Your Press Brake

Touch 24 is an outstanding numerical control for press brakes with a new all-in-one solution

●24 inches surface full touch-screen and the CNC board mounted on the back of the screen.

●Full digital buses controlling many axes

●Unique experience with 2D graphic profile drawing (Touch Profile) and 3D viewer thanks to a new quadcore processor unit.

●Interface to all kind of hydraulic systems, I/O and analog axes thanks to the modules placed inside the cabinets.

In addition to all the features available to controlsimple as well most sophisticated press brakes, hydraulic, electrical and hybrid, Touch offers also an open system allowing customization to be up to the Industry’s 4.0 production management requirements.

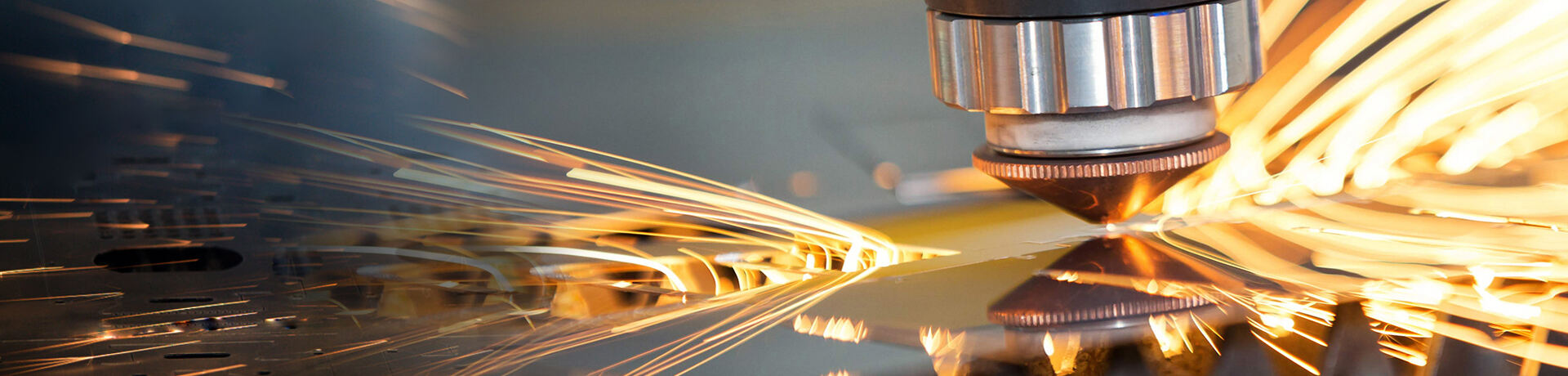

Press Brake Machine Frame Structure

1.Machine frame is of steel welding structure through finite element analysis and optimal design, featuring hi-rigidity and strength.

2.Welding stress is deleted after the annealing treatment for welding parts in the electric furnace, which can avoid the frame deformation in future. Sandblasting remove the rust on the welding parts and the anti-rust painting apply to the welding structure parts.

3.Heat Treatment Processes:JUGAO press brake and laser cutting machine steel frames undergo annealing at over 600⁰ to relieve stress and they are built to last years of heavy use without distortion.

Mechanical compensation workbench (V axis)

Mechanical deflection compensation with high CNC precision is adopted. Since there are many compensation points, the bending machine can realize linear compensation when bending the workpiece during operation, which can improve the bending effect of the workpiece. It has the characteristics of maintenance-free and more accurate compensation

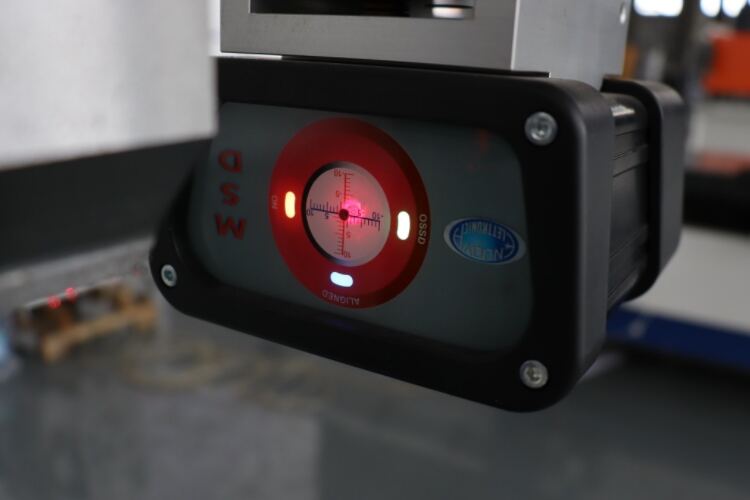

High precision grating ruler

Y1,Y2 axes are two independent CNC axes of two oil cylinders. The linear scale will measure the distance between ram and worktable.Its data will feed back to the control, and after close-loop calculation the servo valve signals S1 and S2 are output to control the output flow of two servo valves.

A high-precision grating ruler is used as the displacement sensor, which is installed on the C-shaped plate to detect the position of the oil cylinder. The feedback accuracy is as high as 0.001mm, which can help better control the bending angle.

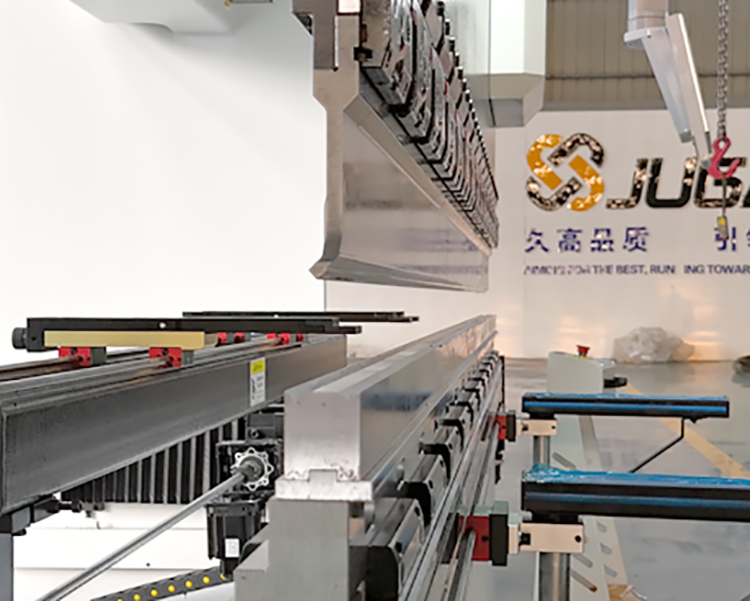

CNC Backgauge

The main support axes of a 4+1-axis CNC bending machine usually include Y1, Y2, X, R and an auxiliary axis for compensation or adjustment. This configuration enables the machine tool to handle more complex bending tasks and improves processing efficiency.

One-key Release Fast Clamp

The one-key release fast clamp could ensure the safe and fast punch changing, with strict quality requirements and procurement standards of raw materials, which keeps the punch from falling out.

Made of high-quality tool steel/high-strength CrMo alloy steel, the maximum load capacity can reach 800 tons/meter, and the hardness after heat treatment can reach 56~60HRC.

Bending machine mold

The material of the bending machine mold is usually high-strength and high-toughness alloy steel 42CrMo. The notch selection of the mold needs to be determined according to the width 8 times of the plate thickness. It is mainly divided into upper mold and lower mold. The shape and size of the mold are customized according to different work requirements. Common ones include standard U-shaped, V-shaped, bottom mold, upper mold, etc.

1.Standard U-shaped mold: used to manufacture standard bending shapes, suitable for most manual and automatic bending machines.

2.Standard V-shaped mold: has a sharper angle and is suitable for plates that require deeper bends.

3.Bottom form: used for bottom bends, with a folded edge used to shape the sheet in the bottom bend angle.

4.Upper die: used to shape the sheet from the top, usually with right angles and semi-circular shapes.

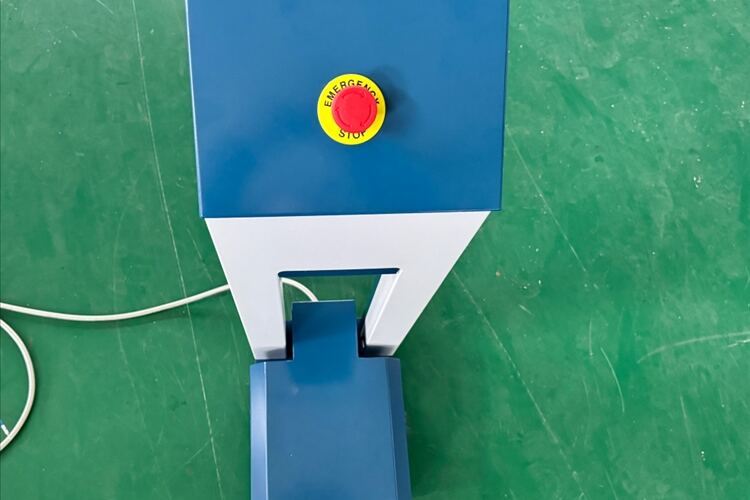

Multifunctional Pedal Switch

JUGAO has upgraded the pedal switch to a new generation, with a single switch design, front-mounted rollers, emergency stop switch, and return button, all for easier and smarter operation.

The multi-function foot switch of the bending machine is an important control device, which allows the operator to achieve precise control of the machine through pedaling movements when operating the bending machine. The design of this switch not only improves the convenience of operation, but also enhances the safety of operation to a great extent.

Safety Light Curtain

The light curtain, JUGAO chooses is from the well-known brands, with perfect performance to offer a highly effective solution for both operator safety and machine productivity.

Using laser light source, it can detect objects as small as 5mm and allow vibration deviation,Once an obstruction enters the protected area, the machine stops immediately, protecting the personal safety of bending operators and avoiding accidents.