- Overview

- Inquiry

- Related Products

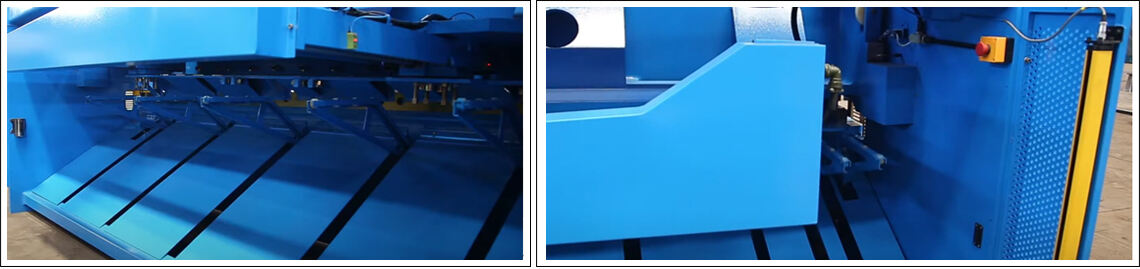

Product Features

1.Cutting angle can be adjusted. It is used for cutting metal sheets of different materials. So as to ensure cutting quality.

2. Four edges of blade can be used. So service life of blade is double that of ordinary machines.

3. Electric blade edge clearance adjustment. Simpler operation.

4. Upward movement of the blade is controller by accumulator . No need to add nitrogen gas in future use.

5. Cutting steel plate with thickness greater than 12mm. The cutting quality is better.

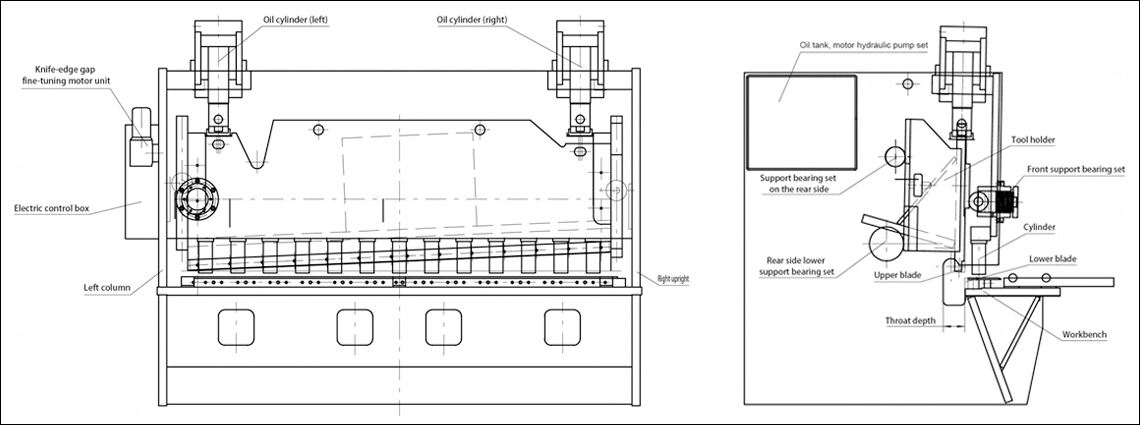

Technical parameter

| Name | Data | Unit | Remarks | ||

| Max cutting thickness | 16 | mm | |||

| Max cutting width | 4000 | mm | |||

| Throat depth | 350 | mm | |||

| Intensity of the sheared material | 500 | N/mm2 | |||

| Maximum support of workbench | 5 | T | |||

| Shearing angle | 1.45°-3° | ||||

| Max stroke of back gauge | 1000mm | ||||

| Times of stroke | 22 | Per/min | |||

| Distance between vertical columns | 4250 | mm | |||

| The length of blade | 4100 | mm | |||

| Height of the work bench | 950 | mm | |||

| Main motor | Model | Y180M-4 | |||

| Power | 18.5 | KW | |||

| Speed | 1400 | rpm | |||

| Back gauge motor | Model | servo motor | B5 | ||

| Power | 0.75 | KW | |||

| Speed | 2000 | rpm | |||

| Blade gap adjust motor | Model | Y802-6 | |||

| Power | 0.37 | KW | |||

| Speed | 900 | rpm | |||

| Gear Pump | Model | LXPG1H-LX1/040R | |||

| Power | 40 | L/min | |||

| Pressure | 31.5 | MPa | |||

| Dimensions | Length | 4250 | mm | ||

| Width | 1780 | ||||

| Height | 2580 | ||||

| Weight | 14000 | Kg | |||

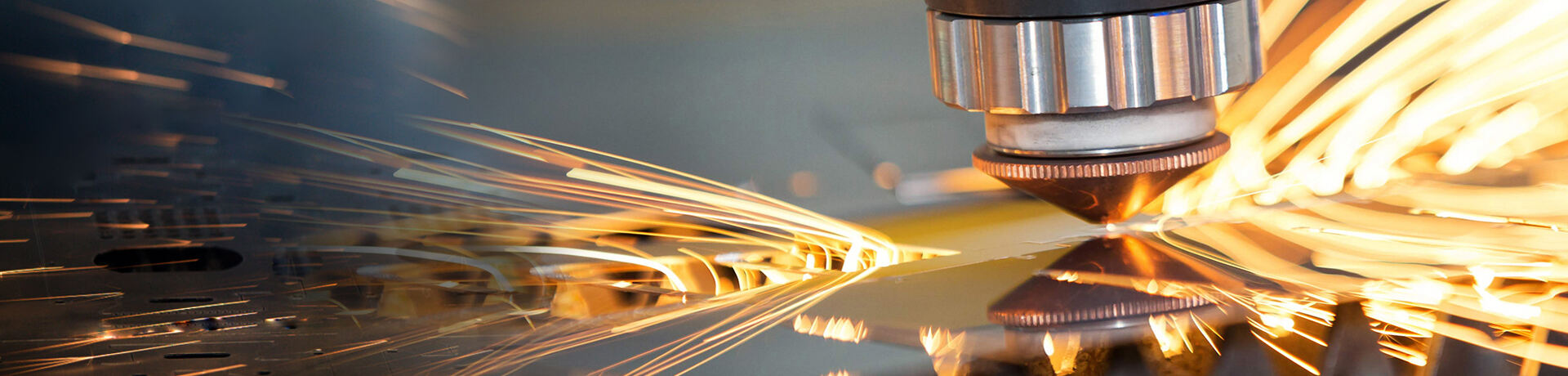

Sample show

Accessories brand list

| No | Acessory Name | Model/Manufactur er | Other | Configuration |

| 1 | CNC System | ☑DELEM DAC360 | Standard | |

| 2 | Electrics | Germany Schneider electric | Travel switch & Limit switch | |

| 3 | Main motor | Siemens motor | ||

| 4 | Frequency Converter | JRACDRIVE | Positioning control | |

| Guaranteed precision | ||||

| 5 | Pedal Switch | South Korea KACON | ||

| 6 | Accumulator | NINGBO | ||

| 7 | Back gauge | Ball screw linear guide rail-Taiwan HIWIN | ||

| 8 | Hydraulic system | Bosch Rexroth Germany | ||

| 9 | Oil pump | Rexroth | ||

| 10 | Sealing ring | PARKER-America | ||

| 11 | Oil tube connector | Casing connector | ||

| 12 | Front safety guard | Produced by ERMAK | ||

| 13 | Back safety guard | Produced by ERMAK | ||

| 14 | Blade | One set of upper and down blade | ||

| 15 | Pressing device | Produced by ERMAK | ||

| 16 | Automatic Feeding Table | Produced by ERMAK | Optional | |

| 17 | Large Throat Gap | Produced by ERMAK | ||

| 18 | Automatic Lubrication System | Produced by ERMAK | ||

| 19 | Front Angle Gauge | Produced by ERMAK | ||

| 20 | Laser cutting line | Produced by ERMAK | ||

| 21 | Cooling System | Produced by ERMAK | ||

| 22 | Back Safety System | Produced by ERMAK | ||

| 23 | Pneumatic support | Produced by ERMAK | ||

| 24 | Light curtain protection | CHINA | ||

| 25 | System options | E200P DA310 | ||

| 26 | Safety standard | ☑CE □CSA ☑NR-12 □OSHA | ||

SPARE PARTS AND SPECIAL TOOLS

| Accessory | ||||

| 1 | GB801-2011 | Bolt M16X500 | Piece | 4 |

| 2 | GB7160-2016 | Nuts M16 | Piece | 4 |

| 3 | GB98-2015 | Inflatable tools | Piece | 1 |

| 4 | GB610-2014 | Electrical box key | Piece | 1 |

| 5 | GB766-2018 | Button box power key | Piece | 2 |

| 6 | GB568-2018 | Foot switch | Piece | 1 |

| Spare parts | ||||

| 7 | GB689-2018 | O type seal ring | Piece | 17 |

| Document | ||||

| 1 | Manual Operation Book | Copy | 1 | |

| 2 | Certification of CE | Copy | 1 | |

| 3 | Packing list/Commercial Invoice( Certification of Origin) | Copy | 1 | |

| 4 | Inspection Qualified | Copy | 1 | |

OPITING PART

Delem DA360 Controller:https://youtu.be/1LS4YJWPRro

Controller

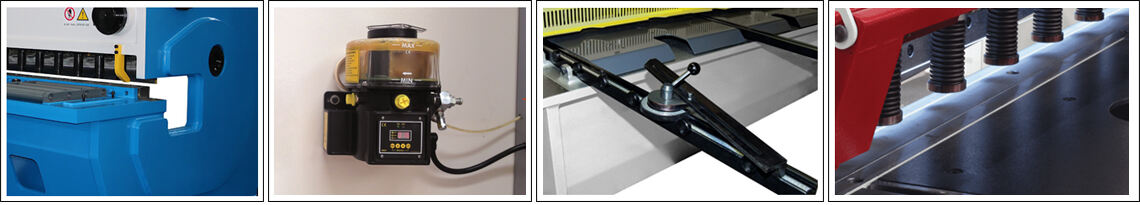

Large Throat GapAutomatic Lubrication SystemFront Angle GaugeLaser cutting line

Cooling SystemAutomatic Feeding Table

Automatic Feeding Table Back Safety System